Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  IsiNgisi

IsiNgisi  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Izisetshenziswa Zethu Zomugqa Wokukhiqiza

Ukulawulwa kwenqubo: Inqubo eyinhloko yenkampani yethu yokukhiqiza ama-roller ihlukaniswe ngezinyathelo eziyi-13, ngasinye sazo sisebenzisa amathuluzi nezinto ezizinikezele.

-

UKUTHWALA KWEZINDLU FLANGINGInqubo ye-flanging yesihlalo esithwalayo ihilela ukwelula unqenqema lwangaphandle lwesihlalo esithwalayo emuva ukuze uvumelane nodonga lwangaphakathi lwepayipi lokuthintana kwendawo. Uma ifakwe kwipayipi, ingaba nendawo enkulu yokuxhumana kanye nokuphazamiseka okufanelekile nokufana okufanayo, ukuze isihlalo esithwalayo sifakwe ngokuqinile kwipayipi futhi sigweme i-welding deformation. Ngale nqubo, ubuso bokugcina besihlalo sokuthwala buqhubeka nokubunjwa futhi akusaphindi. Ukushwibeka kanye nokuphuma kwe-radial kobuso bokuphela kwesihlalo esinesihlalo esinesihlalo esine-axis kungalawulwa ngaphakathi kuka-0.1mm. Nikeza isiqinisekiso senqubo yokufaka elandelayo.

-

IBHA LESTEEL LOKUSIKA ISHAFTUkusika kwe-shaft kuqedwa kusetshenziswa umshini wokusaha, futhi ubude bokusika bulungiswa kusayizi oyisisekelo ± 0.5mm. Ukusika umshini wokusaha kungagwema ukugoba kwangaphandle kwe-shaft ngesikhathi sokucubungula. (Umsebenzisi ugcwalisa ifomu lerekhodi lenqubo)

-

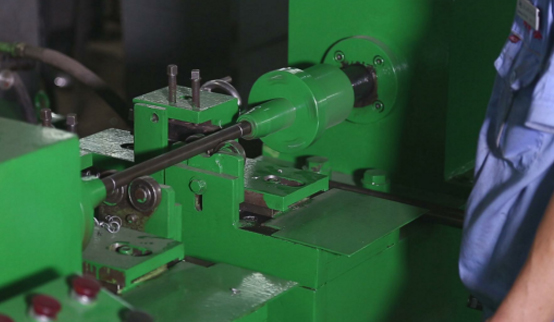

I-SHAFT CHAMFERINGInqubo ye-shaft chamfering iqedwa ngokubhola okuyisicaba okuzinikezele, futhi i-cutterhead ifakwe idivayisi yokumisa ukulawula usayizi we-chamfer, iqinisekisa usayizi we-chamfer ongaguquki. Futhi ukusebenza kahle kuphezulu kakhulu. Ngokuvamile, abasebenzi bangaqedela izingcezu eziyi-1500-2000 ngokushintshana ngakunye.

-

GROOVE PROCESSINGFaka okokusebenza kwe-slot ukuze kucutshungulwe ama-roller shafts, nquma inani lokucutshungulwa ngakunye ngokusekelwe kubude nobubanzi be-shaft, futhi ngemva kokumiswa, yenza ukucubungula kokuphakelayo kokugcina ukuze uqinisekise ububanzi obunembile begroove nokujula kweqoqo ngalinye lokucubungula. Ikilasi elilodwa lingaqeda imisebenzi engu-800-1200. (Umsebenzisi ugcwalisa ifomu lerekhodi lenqubo).

-

CIRCLIP GROOVE PROCESSINGIcubungula imishini ye-spring groove yekhadi, ukugoqa okuzenzakalelayo, ukusika okuzenzakalelayo kwe-double groove. Inenzuzo yebanga eliqondile phakathi kwezikhala ezimbili nokusebenza kahle okuphezulu. Isivuno sekilasi sisukela ezimpandeni eziyi-1000 kuye kweziyi-1500. (Umsebenzisi ugcwalisa ifomu lerekhodi lomsebenzi).

-

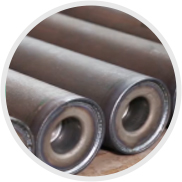

UKUSIKA AMAPHAPHA ENSIMBAUkusika amapayipi kungaqedela ngokuzenzakalelayo ukuphakela, ukubopha, nokusika, futhi wonke umjikelezo wamapayipi uyaphothulwa. Ukukhishwa kwekilasi kungafinyelela izingcezu ezingama-500-1000.

-

I-BEVELLING ENGAPHAKATHIUkuphela kwepayipi okuyisicaba kanye namakhona angaphakathi nangaphandle emoto kungalawulwa ngaphakathi kwamamilimitha angu-± 0.1 ubude ngemva kokucubungula. Lokhu kunikeza izimo ezinhle zokulawula ukunemba kokufakwa kwe-axial komhlangano we-roller esikhathini esizayo. Ukukhiqizwa kwekilasi kungaqedela kalula izingcezu ze-800-1500.

-

OKUQHUBEKA KWEPIPE YESIBILIKuqedwe emshinini wokudubula we-sandblasting wensimbi ukuze kukhishwe i-iron oxide futhi kunikeze indawo ehlanzekile yokufafaza nge-electrostatic, okuthuthukisa ukunamathela kwefilimu kapende.

-

UKUTHWALA KWEZINDLU CHAMFERINGInhloso ye-chamfering isihlalo esithwalayo ukwenza kube lula ukufakwa lapho isihlalo esithwalayo sicindezelwa epayipini.

-

UKUTHWALA IZINDLU OKUPHINDEZAUkuhlanganiswa kwesihlalo esithwalayo kanye nepayipi kudinga ububanzi obungaphandle besihlalo esithwalayo ukuba bukhulu kunobubanzi bangaphakathi bepayipi ngamamilimitha angu-0.05-0.15. I-tooling igxilise ngaphambili isihlalo esiphethe kanye nepayipi, futhi isihlalo esiphethe sine-chamfer enkulu, engacindezelwa ngokushelelayo epayipini bese yenza ukuphazanyiswa okuhambisana nepayipi ukuze kufakwe. Ngenxa yokuthi udonga lwangaphakathi lwepayipi alucutshungulwanga ngezinto ezisusiwe, ngeke kube namaphutha okucubungula aqoqiwe. Kungase futhi kube nomthelela wokulungisa ku-ellipse yasekuqaleni yepayipi.

-

Ukulawulwa kokuphuma kwendilinga ngemuva kokuhlanganiswa kwe-roller kunenzuzo kakhulu. Ukujula okucindezelayo kwesihlalo esinesihlalo kulawulwa yi-fixture, ehambisanayo iyonke futhi engakwazi ukulawula ibanga phakathi kwamakamelo amabili okuthwala ngaphakathi kwamamilimitha angu-± 0.1. Lokhu kunikeza isiqinisekiso esinokwethenjelwa sokulawula ukunyakaza kwe-axial kwama-roller.

-

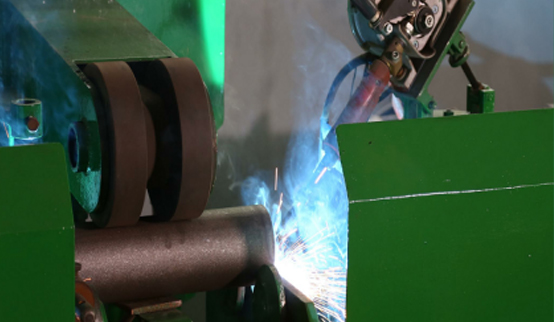

ITHWELE UKUSHISELA KWEZINDLU NGOMZIMBA WEPIPE LESTEELUmzimba wepayipi onesihlalo sokuthwala esifakiwe ushiselwe lapha, futhi i-welding iqala nge-arc ngesikhathi sokujikeleza kwe-workpiece, futhi i-arc icishiwe nganoma iyiphi i-engeli (360 °+). Ukushisela kokubili kugcina ngesikhathi esisodwa, ngoba kukhona i-arc eyindilinga lapho upheqa isihlalo esithwalayo, kwakhiwa i-groove ejwayelekile endaweni yokushisela ngemva kokufakwa, okwenza i-welding iqine, i-weld ibe yinhle, kanye ne-deformation encane. (Umsebenzisi ugcwalisa ifomu lerekhodi lokuqapha inqubo ekhethekile)

-

UMHLANGANOUkuhlanganisa ama-rollers kuqediwe emshinini wokunyathelisa, kuhlukaniswe izingxenye ezimbili: ukuhlanganisa ama-bearings nokuhlanganisa izimpawu. Okokuqala, faka futhi uhlole ama-bearings. Uma zingekho izinkinga, bese ufaka izimpawu. Isigxivizo esinezithombe siwumkhiqizo onelungelo lobunikazi wenkampani. Indandatho ye-snap esetshenziselwa ukulawula i-axial iseduze kakhulu ne-bearing, futhi asikho isikhala sokuguqulwa uphawu. Umphumela wokulawula i-axial muhle kakhulu. I-roller ihlukaniswe yaba yi-labyrinth kanye nophawu lwezigaba ezimbili zokuxhumana, ne-seal yokuxhumana kanye ne-shaft ngokuthintana okuqondile, okuholela ekuphikiseni okuncane kakhulu.

-

UKUHLOLA NOKUHLANZAHlanza ingaphezulu le-roller ehlanganisiwe futhi uhlole ukukhubazeka kwendawo kanye nokuguquguquka kokujikeleza kwe-roller. Ukuhlonza ngaphandle kokulimala kugcinwa endaweni yokugcina impahla. (Umhloli wekhwalithi ugcwalisa ithebula lemininingwane yendawo yokugcina impahla)