Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Turanci

Turanci  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Kayan Aikin Layi Namu

Gudanar da tsari: Babban tsarin kamfaninmu na samar da rollers ya kasu kashi 13 matakai, kowannensu yana amfani da kayan aiki da kayan aiki.

-

KYAUTA GIDAN FLANGINGTsarin flanging na wurin zama ya haɗa da shimfiɗa gefen waje na wurin zama a baya don dacewa da bangon ciki na bututun Tuntuɓi. Lokacin da aka sanya shi akan bututun, zai iya samun babban wurin tuntuɓar sadarwa da dacewa da tsangwama iri ɗaya, ta yadda za'a iya shigar da wurin zama da ƙarfi akan bututun kuma a guji nakasar walda. Ta wannan tsari, ƙarshen fuskar wurin zama yana ƙara siffa kuma baya sake komawa. A lilo da radial runout na bearing wurin zama karshen fuska da hali wurin zama axis za a iya sarrafa a cikin 0.1mm. Samar da tabbaci don tsarin shigarwa na gaba.

-

YANKAN KARFE KARFE GA SHAFTAn kammala yankan shinge ta amfani da na'ura mai shinge, kuma an daidaita tsayin yanke zuwa girman girman ± 0.5mm. Yanke na'ura na iya guje wa lankwasawa na waje yayin aiki. (Mai aiki ya cika fom ɗin rikodin tsari)

-

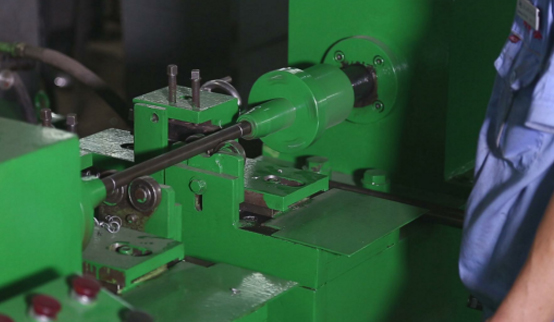

SHAFT CHAMFERINGAn kammala aikin chamfer na shaft ta hanyar rawar gani mai fa'ida, kuma mai yankan yana sanye da na'urar sanyawa don sarrafa girman chamfer, yana tabbatar da daidaitaccen girman chamfer. Kuma ingancin yana da yawa sosai. Gabaɗaya, ma'aikata na iya kammala guda 1500-2000 a kowane motsi.

-

HANYAR GIRMAShigar da kayan aikin ramin don sarrafa ramukan abin nadi, ƙididdige adadin kowane aiki dangane da tsayi da diamita na shaft, sannan bayan sanyawa, aiwatar da sarrafa abincin niƙa don tabbatar da ingantacciyar faɗin tsagi da zurfin ga kowane tsari na sarrafawa. Aji ɗaya na iya kammala ayyuka 800-1200. (Mai aiki ya cika fom ɗin rikodin tsari).

-

HANYAR SARAUTAR CIRCLIP GROOVEProcessing katin spring tsagi kayan aiki, atomatik clamping, biyu tsagi atomatik sabon. Yana da fa'idar madaidaicin nisa tsakanin ramummuka biyu da ingantaccen inganci. Yawan amfanin ajin ya bambanta daga tushen 1000 zuwa 1500. (Mai aiki ya cika fom ɗin rikodin aikin aiki).

-

YANKAN BUBUWAN KARFEYanke bututu na iya kammala ciyarwa ta atomatik, matsawa, da yanke ayyukan, kuma an gama zagayowar bututu gabaɗaya. Fitowar ajin na iya kaiwa guda 500-1000.

-

KARSHEN BANZAƘarshen ƙarshen bututu da kusurwoyi na ciki da na waje na motar za a iya sarrafa su a cikin ± 0.1 millimeters tsawon bayan aiki. Wannan yana ba da yanayi mai kyau don sarrafa daidaitattun daidaiton axial na taron nadi a nan gaba. Samar da ajin na iya sauƙaƙe 800-1500 guda.

-

BUBUWAN KARFE YANCIAn kammala shi a cikin injin harbin sandblasting na ƙarfe don cire baƙin ƙarfe oxide da samar da wuri mai tsabta don feshin electrostatic, haɓaka mannewa na fim ɗin fenti.

-

KYAUTA GIDAManufar chamfer wurin zama shine don sauƙaƙe shigarwa lokacin da aka danna wurin zama a cikin bututu.

-

HANYAR HANYAR GIDAHaɗin wurin zama da bututu yana buƙatar diamita na waje na wurin zama ya zama mafi girma fiye da diamita na ciki na bututu ta 0.05-0.15 millimeters. Kayan aiki ya riga ya kasance a tsakiya da wurin zama da bututu, kuma wurin zama yana da babban chamfer, wanda za'a iya danna shi cikin bututu kuma ya samar da tsangwama tare da bututu don shigarwa. Saboda bangon ciki na bututu ba a sarrafa shi tare da cire kayan aiki ba, ba za a sami kurakurai masu tarin yawa ba. Hakanan yana iya samun tasirin gyara akan ainihin ellipse na bututu.

-

Gudanar da runout madauwari bayan taron nadi yana da amfani sosai. Zurfin matsi na wurin zama yana sarrafawa ta hanyar daidaitawa, wanda ya dace da gaba ɗaya kuma yana iya sarrafa nisa tsakanin ɗakunan ɗakuna biyu a cikin ± 0.1 millimeters. Wannan yana ba da tabbacin abin dogara don sarrafa motsi na axial na rollers.

-

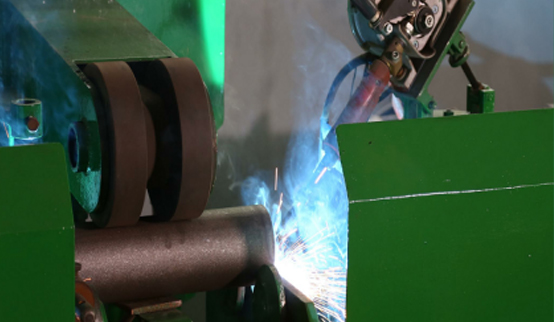

ALAMOMIN WANGA GIDA TARE DA JIKIN BUTUN KARFEJikin bututu tare da wurin zama mai ɗaukar nauyi yana waldawa anan, kuma waldi yana farawa da baka yayin jujjuyawar aikin, kuma an kashe baka a kowane kusurwa (360 °+). Welding biyu yana ƙarewa lokaci guda, saboda akwai madauwari baka lokacin jujjuya wurin zama, an kafa daidaitaccen tsagi a wurin walda bayan shigarwa, yana mai da masana'antar walda, walda mai kyau, kuma nakasar ƙanƙanta. (Mai aiki ya cika fom ɗin rikodin sa ido na musamman)

-

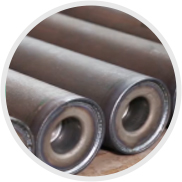

MAJALIYYAAna gama haɗa rollers a cikin injin daskarewa, an raba shi zuwa sassa biyu: haɗa bearings da haɗuwa da hatimi. Da farko, shigar da gwada bearings. Idan babu matsaloli, to shigar da hatimi. Hatimin da aka kwatanta samfurin kamfani ne. Zoben karye da ake amfani da shi don sarrafa axial yana kusa da ɗaukar hoto, kuma babu sarari nakasawa a hatimin. Sakamakon kula da axial yana da kyau sosai. An raba abin nadi zuwa labyrinth da lambar hatimin mataki biyu, tare da hatimin lamba da shaft a cikin lamba kai tsaye, yana haifar da juriya kaɗan.

-

GWADA DA TSAFTATsaftace saman abin nadi da aka haɗa kuma bincika lahanin saman da sassauci a jujjuyawar abin nadi. Ana adana ganewar ba tare da lahani ba a cikin sito. (Mai duba ingancin ya cika cikakkun bayanai game da wuraren ajiyar kayan da aka gama)