Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  IsiNgesi

IsiNgesi  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu IsiXhobo sethu soMmandla wokuVelisa

Ulawulo lwenkqubo: Inkqubo ephambili yenkampani yethu yokuvelisa i-roller ihlukaniswe ngamanyathelo angama-13, ngalinye lisebenzisa izixhobo ezizinikeleyo kunye nezixhobo.

-

UKUTHWALA KWEZINDLU FLANGINGInkqubo ye-flanging yesihlalo sokuthwala ibandakanya ukunweba umda wangaphandle wesihlalo sokuthwala ngasemva ukuze uvumelane nodonga lwangaphakathi lombhobho Uqhagamshelwano lombhobho. Xa ifakwe kumbhobho, ingaba nomgangatho omkhulu wokudibanisa kunye nokulungelelaniswa okufanelekileyo kunye nokuphazamiseka okufanayo, ukwenzela ukuba isihlalo sokuthwala sifakwe ngokuqinileyo kumbhobho kwaye sigweme i-welding deformation. Ngale nkqubo, isiphelo sobuso besihlalo sokuthwala sibunjwa ngakumbi kwaye asisaphindi. I-swing kunye ne-radial runout ye-bearing seat isiphelo sobuso kunye ne-axis yesihlalo esinesihlalo sinokulawulwa ngaphakathi kwe-0.1mm. Ukubonelela ngengqinisekiso yenkqubo yofakelo elandelayo.

-

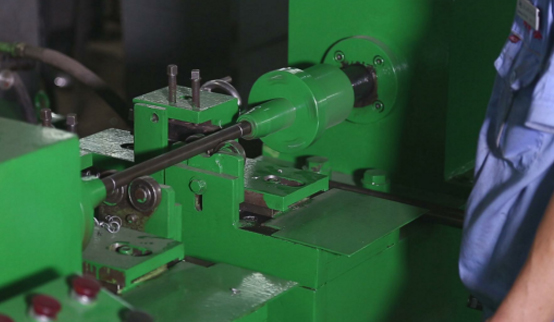

UKUSIKA IBHA YE-STEEL UKUZE SHAFTUkusika kwe-shaft kugqitywe ngokusebenzisa umatshini wokusarha, kwaye ubude bokusika bulungelelaniswa nobukhulu obusisiseko ± 0.5mm. Ukusika umatshini we-Sawing kunokuphepha ukugoba kwangaphandle kwe-shaft ngexesha lokucubungula. (Umsebenzi ugcwalisa ifomu yerekhodi yenkqubo)

-

I-SHAFT CHAMFERINGInkqubo ye-shaft chamfering igqitywe nge-drill ezinikeleyo, kwaye i-cutterhead ixhotyiswe ngesixhobo sokumisa ukulawula ubungakanani be-chamfer, ukuqinisekisa ubungakanani be-chamfer obuhambelanayo. Kwaye ukusebenza kakuhle kuphezulu kakhulu. Ngokubanzi, abasebenzi banokugqiba amaqhekeza angama-1500-2000 kwishifti nganye.

-

IGROOVE PROCESSINGFaka izixhobo zokurhweba ukwenzela ukusetyenzwa kweeshafti ze-roller, misela ubuninzi bomsebenzi ngamnye ngokusekelwe kubude kunye nobubanzi be-shaft, kwaye emva kokubeka indawo, yenza inkqubo yokutya yokugaya isiphelo ukuqinisekisa ububanzi obuchanekileyo kunye nobunzulu bebhetshi nganye yokucubungula. Iklasi enye inokugqiba imisebenzi engama-800-1200. (Umsebenzi ugcwalisa ifomu yerekhodi yenkqubo).

-

I-CIRCLIP GROOVE PROCESSINGIkhadi lokucutshungulwa kwezixhobo ze-spring groove, i-clamping ezenzekelayo, i-double groove yokusika ngokuzenzekelayo. Inenzuzo yomgama ochanekileyo phakathi kweendawo zokubeka ezimbini kunye nokusebenza okuphezulu. Isivuno seklasi sisuka kwi-1000 ukuya kwiingcambu ze-1500. (Umsebenzi ugcwalisa ifomu yerekhodi yomsebenzi).

-

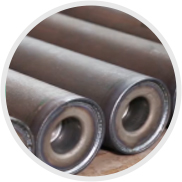

UKUSEKA IMIbhobho yentsimbiUkusika umbhobho kunokugqiba ngokuzenzekelayo ukutya, ukumbamba, kunye nokusika izenzo, kwaye umjikelezo wonke wombhobho ugqityiwe. Imveliso yeklasi inokufikelela kumaqhekeza angama-500-1000.

-

I-BEVELLING EPHELELEYOUkuphela kwecala lombhobho kunye neekona zangaphakathi nangaphandle zemoto zingalawulwa ngaphakathi kwe-± 0.1 millimeters ubude emva kokucubungula. Oku kunika iimeko ezilungileyo zokulawula ukuchaneka kwe-axial ye-roller assembly kwixesha elizayo. Imveliso yeklasi inokugqiba ngokulula iziqwenga ze-800-1500.

-

UMbhobho WESENTI UKUDUMBUZWA KWESANDIIgqitywe kumatshini we-sandblasting wentsimbi yokudutyulwa kwentsimbi ukususa i-iron oxide kunye nokubonelela indawo ecocekileyo yokutshiza i-electrostatic, ukuphucula ukunamathela kwefilimu yepeyinti.

-

UKUBHALELA IZINDLU CHAMFERINGInjongo ye-chamfering isihlalo sokuthwala kukuququzelela ukufakwa xa isihlalo sokuthwala sicinezelwe kumbhobho.

-

UKUTHWALA INDLU UXINEZELEKILEYOUkuhlanganiswa kwesihlalo sokuthwala kunye nombhobho kufuna ukuba ububanzi bangaphandle besihlalo sokuthwala bube bukhulu kunobubanzi bangaphakathi bombhobho nge-0.05-0.15 millimeters. Isixhobo sokuxhobisa ngaphambili sigxininise isihlalo sokuthwala kunye nombhobho, kwaye isihlalo sokuthwala sine-chamfer enkulu, enokuthi icinezele ngokucokisekileyo kumbhobho kwaye yenze ukuphazamiseka okuhambelana nombhobho wofakelo. Ngenxa yokuba udonga lwangaphakathi lombhobho aluzange lucutshungulwe ngezinto ezisusiweyo, akuyi kuba neempazamo zokucubungula eziqokelelweyo. Kwakhona kunokuba nempembelelo yokulungiswa kwi-ellipse yasekuqaleni yombhobho.

-

Ukulawulwa kokuphuma kwesetyhula emva kwendibano ye-roller kunenzuzo kakhulu. Ubunzulu obucinezelayo besihlalo sokuthwala bulawulwa yi-fixture, ehambelanayo yonke kwaye inokulawula umgama phakathi kwamagumbi amabini okuthwala ngaphakathi kwe-± 0.1 millimeters. Oku kunika isiqinisekiso esithembekileyo sokulawula ukuhamba kwe-axial yee-roller.

-

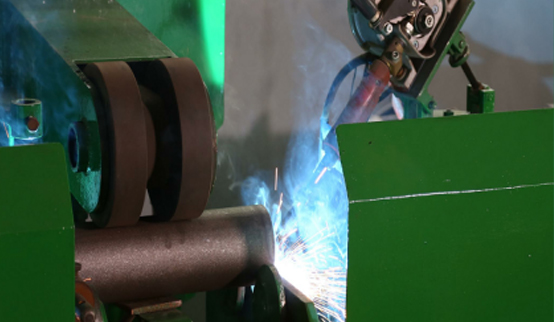

UKUTHWALA I-WELDING YEZINDLU NGOMbhobho WE-STEEL BODYUmzimba wombhobho onesitulo sokuthwala esifakelweyo udityaniswe apha, kwaye i-welding iqala nge-arc ngexesha lokujikeleza kwe-workpiece, kwaye i-arc icinyiwe kuyo nayiphi na i-angle (360 °+). I-Welding zombini iziphelo ngaxeshanye, kuba kukho i-arc ejikelezayo xa uguqula isihlalo sokuthwala, i-groove esemgangathweni yenziwa kwindawo ye-welding emva kokufakwa, ukwenza i-welding iqine, i-weld ihle, kunye ne-deformation encinci. (Umsebenzi ugcwalisa ifomu yokurekhoda inkqubo ekhethekileyo)

-

INDIBANOUkudibanisa i-roller kugqityiwe kumatshini wokushicilela, ulwahlulo lwamacandelo amabini: ukudibanisa iibheringi kunye nokudibanisa izitywina. Okokuqala, faka kwaye uvavanye iibheringi. Ukuba akukho ngxaki, ke faka izitywina. Isitywina esinemizobo yimveliso enelungelo elilodwa lomenzi wenkampani. Iringi ye-snap esetyenziselwa ulawulo lwe-axial isondele kakhulu kwi-bearing, kwaye akukho ndawo yokuguqulwa kwesitywina. Impembelelo yokulawula i-axial ilungile kakhulu. I-roller ihlulwe ibe yi-labyrinth kunye ne-contact-step-seal seal, kunye ne-contact seal kunye ne-shaft ngokuqhagamshelana ngokuthe ngqo, okubangelwa ukuchasana okuncinci.

-

UKUVAVANYA NOKUCOCACoca umphezulu we-roller edibeneyo kwaye ukhangele iziphene zomhlaba kunye nokuguquguquka ekujikelezeni kwe-roller. Ukuchongwa ngaphandle kweziphene kugcinwa kwindawo yokugcina impahla. (Umhloli womgangatho uzalisa itafile yeenkcukacha zokugcina imveliso egqityiweyo)