Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Ingelsk

Ingelsk  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Rubber Lagging Pulley

Detail Beskriuwing

Detail Beskriuwing

De soarten rubber dy't brûkt wurde kinne om de trommel te dekken binne: NBR, CR, HYPLON, PU, SBR, SR, ensfh. Hokker kin wurde oanpast neffens jo produkt mei help fan miljeu- en produktûntwerpeasken.

Produkt Parameters

Produkt Parameters

General rubber performance parameters as follows:

- 1: Fysike en meganyske eigenskippen fan oerflak rubber:

| Test items |

Fersyk |

Echt test |

Konklúzje |

|

| MPa treksterkte (Mpa) |

≥18 |

20 |

kwalifisearre |

|

| Ferlinging by brek (%) |

≥300 |

317 |

kwalifisearre |

|

| Permaninte set fan pull-apart (%) |

≤25 |

24 |

kwalifisearre |

|

| SHAW type A hurdens |

Pulley bûge |

60~70 |

70 | kwalifisearre |

|

Driving pulley |

≥70 |

|||

| Slijtageferlies (mm3) |

≤90 |

88 | kwalifisearre | |

| aging coefficient(70℃×168h) |

treksterkte |

-25~+25 | 20 | kwalifisearre |

|

feroaring taryf (%) |

||||

|

Ferlinging |

||||

|

by break feroaring rate |

||||

2: Fysike en meganyske eigenskippen fan boaiem rubber:

|

Test items |

Fersyk |

Echt test |

Konklúzje |

|

MPa spanning l e-sterkte (Mpa) |

≥30 |

30 |

kwalifisearre |

|

elongation at break(%) |

≥300 |

330 |

kwalifisearre |

|

anty-ôfbraaksterkte (Mpa) |

≥69 |

80 |

kwalifisearre |

|

heat-resistance (℃) |

80 |

85 |

kwalifisearre |

|

Adhesion strength between rubber and metal(Mpa) |

≥4.0 |

4.9 |

kwalifisearre |

|

Adhesion strength between rubber and metal after heat treatment(Mpa) (hot air method for heat treatment,temperature 1452±2℃,time:150 minutes.) |

≥3.2 |

5 |

kwalifisearre |

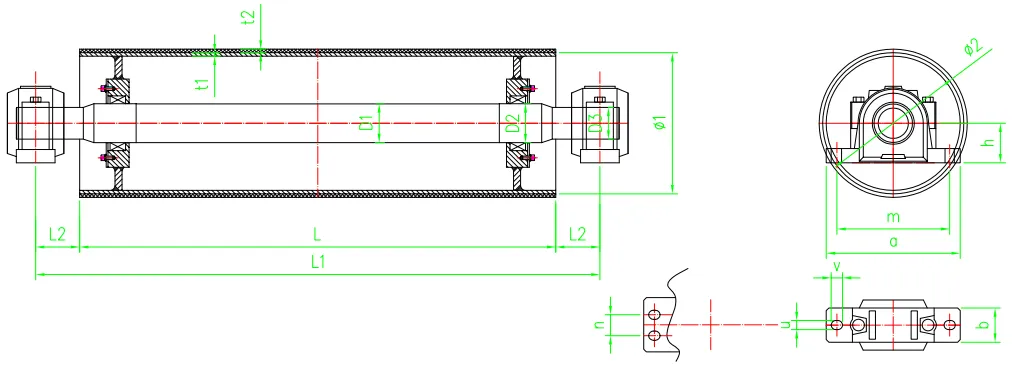

Diagrammatic Drawings and Parameters

Diagrammatic Drawings and Parameters

Diagrammatic Drawings and Parameters for Rubber Lagging Pulley:

|

Riembreedte (mm) |

Φ1 |

Φ2 |

L |

L1 |

L2 |

D1 |

D2 |

D3 |

t1 |

t2 |

a |

m |

h |

b |

n |

u |

v |

Remarks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|