Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 07, 2025 03:59

Back to list

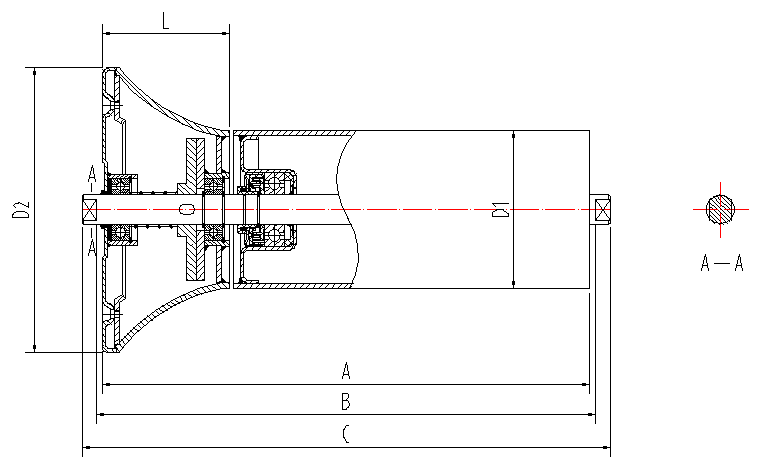

conveyor bend pulley

The world of conveying systems has seen remarkable advancements in recent decades, driven by the need for efficiency, safety, and sustainability. As a cornerstone of any conveyor system, conveyor pulleys have transitioned from being simple components to highly engineered devices pivotal in numerous industrial applications. Catered with steadfast experience in the machinery and manufacturing industry, this article is crafted to deep dive into the nuances of conveyor pulley catalogues, showcasing expertise, instilling trust, and offering authoritative insights for professionals seeking to optimize their operational facilities.

Moreover, surface finishes on pulleys are getting extensive focus, with advancements aimed at reducing belt slippage, especially under high-load conditions. Techniques such as diamond rubber lagging and ceramic lagging have emerged, providing an exemplary resistance to wear and improved grip compared to traditional methods. Expertise in selection extends to understanding operational requirements thoroughly. An experienced engineer should analyze factors like belt tension, load capacity, conveyor speed, and environmental conditions. Furthermore, for heavy-duty applications, split cylindrical roller bearings are recommended, offering easy maintenance and superior load handling capabilities. Authoritativeness is gained by ensuring specifications from the catalogue align with international standards such as ISO 9001, ASME standards, and industry-specific certifications. This helps decision-makers in industries as diverse as mining, automotive manufacturing, or logistics to ensure they are investing in components that will deliver consistent, reliable performance under varying conditions. Trustworthiness, meanwhile, is reinforced by selecting suppliers who have a proven track record of innovation and reliability. Companies with a commitment to quality assurance processes, documented testing standards, and after-sales support foster trust and drive customer loyalty. As industries increasingly pursue automation, global supply chains lean heavily on the efficiency provided by conveyor systems. A well-composed conveyor pulley catalogue serves as an invaluable resource, juxtaposing complex technical data with practical insights. It not only aids engineers and procurement specialists in making informed decisions but also plays a crucial role in optimizing equipment life cycles, and ultimately, achieving operational excellence. This exploration into the strategies for crafting a conveyor pulley catalogue emphasizes a holistic approach—considering real-world experience, expert knowledge, authoritative specifications, and a cornerstone of trust—essential elements for professionals navigating the evolving landscape of materials handling technology.

Moreover, surface finishes on pulleys are getting extensive focus, with advancements aimed at reducing belt slippage, especially under high-load conditions. Techniques such as diamond rubber lagging and ceramic lagging have emerged, providing an exemplary resistance to wear and improved grip compared to traditional methods. Expertise in selection extends to understanding operational requirements thoroughly. An experienced engineer should analyze factors like belt tension, load capacity, conveyor speed, and environmental conditions. Furthermore, for heavy-duty applications, split cylindrical roller bearings are recommended, offering easy maintenance and superior load handling capabilities. Authoritativeness is gained by ensuring specifications from the catalogue align with international standards such as ISO 9001, ASME standards, and industry-specific certifications. This helps decision-makers in industries as diverse as mining, automotive manufacturing, or logistics to ensure they are investing in components that will deliver consistent, reliable performance under varying conditions. Trustworthiness, meanwhile, is reinforced by selecting suppliers who have a proven track record of innovation and reliability. Companies with a commitment to quality assurance processes, documented testing standards, and after-sales support foster trust and drive customer loyalty. As industries increasingly pursue automation, global supply chains lean heavily on the efficiency provided by conveyor systems. A well-composed conveyor pulley catalogue serves as an invaluable resource, juxtaposing complex technical data with practical insights. It not only aids engineers and procurement specialists in making informed decisions but also plays a crucial role in optimizing equipment life cycles, and ultimately, achieving operational excellence. This exploration into the strategies for crafting a conveyor pulley catalogue emphasizes a holistic approach—considering real-world experience, expert knowledge, authoritative specifications, and a cornerstone of trust—essential elements for professionals navigating the evolving landscape of materials handling technology.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS