Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Ceramic Rubber Pulley(Ceramic Lagging Rubber Pulley)

Detail Description

Detail Description

The ceramic rubber plate is made up of special rubber and ceramic block (aluminum oxide ceramic block CK). There are particles on the surface of the ceramic block with excellent wear resistance, which can provide excellent grip between the driving drum and the conveyor belt. It can be used in a variety of extreme working conditions, such as muddy, wet, and high-wear environments.

- 1, The rubber groove between the ceramic blocks ensures maximum drainage.

2, the high-quality rubber at the bottom of the ceramic can effectively reduce the wear between the conveyor belt and the driving pulley.

- 3, The ceramic-coated material has a cold vulcanized CN layer, which can act with SC2000 or SC4000 to achieve strong bonding with the surface of the pulley.

Product Parameters

Product Parameters

|

Parameters for Ceramic Rubber Lagging Pulley |

|

|

Description |

Ceramic Rubber Lagging Pulley |

|

Application |

Used in power, metallurgy, mining, coal, cement, steel, chemicals, seaport, hydropower and grain industries |

|

Material/Diameter/Length of the Drum Body |

1)Material:Carbon Steel,Q235,Q355 2)OD:219mm-2000mm 3)length:500mm-6000mm |

|

Shaft |

Material:#45,42CrMo |

|

Expansion Sleeve Brand |

Z9、RINGFEDER、RINGSPANN、BIKON,FENNER |

|

Bearing |

Double row aligning cylindrical bearing(HRB ZWZ LYC NSK NTN TIMKEN NSK FAG SKF) |

|

Welding |

Automatic welding |

|

Color |

Red,gray,blue or according to requirement |

|

Service Life |

Exceeding 30000 hours |

|

Standards |

GB、ISO、DIN、CEMA、JIS |

|

Balance |

G40 |

Diagrammatic Drawings and Parameters

Diagrammatic Drawings and Parameters

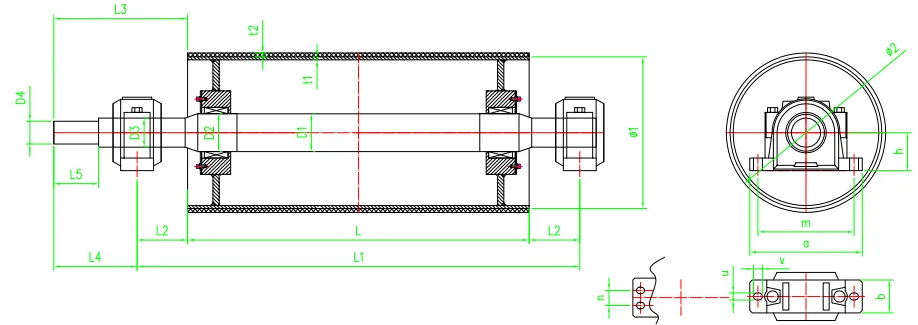

Diagrammatic Drawings and Parameters for Ceramic Rubber Pulley(Ceramic Lagging Rubber Pulley):

|

Belt Width (mm) |

Φ1 | Φ2 | L | L1 | L2 | L3 | L4 | L5 | D1 | D2 | D3 | D4 | t1 | t2 | a | m | h | b | n | u | v | Remarks |