Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 07, 2025 03:35

Back to list

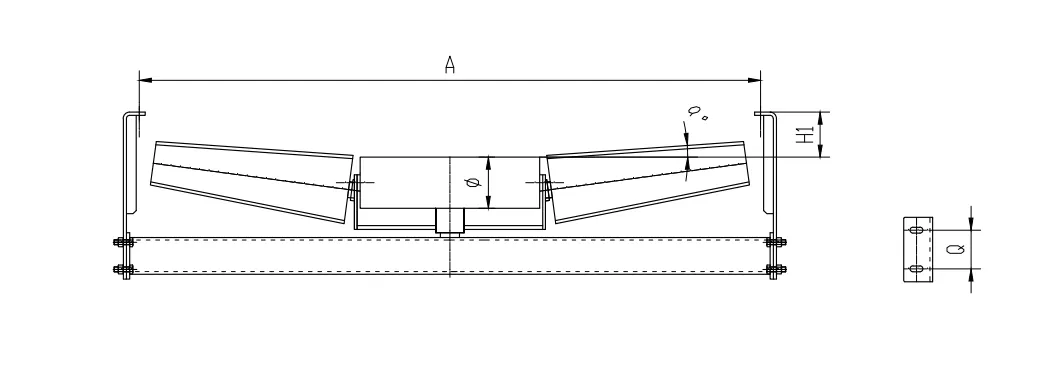

conveyor drum

Conveyor drums, the pivotal components of conveyor systems, play a crucial role in the smooth operation of various industries, including mining, manufacturing, and food processing. Throughout my two decades of experience in engineering and industrial design, I've witnessed firsthand how these essential tools impact production lines. Here, I delve into the intricacies of conveyor drums, providing insights based on professional expertise and practical experience, ensuring a high level of authority and trustworthiness in the discussion.

Furthermore, the advent of eco-friendly conveyor drum solutions has revolutionized the industry. Drums crafted from recycled materials are not only sustainable but also come with enhanced properties such as reduced weight and improved energy efficiency. The shift towards greener practices echoes an industry-wide commitment to environmental stewardship, marking a turning point in how conveyor systems are viewed in the context of sustainability. Trustworthy and reliable conveyor drum suppliers distinguish themselves through rigorous quality control and certification processes. ISO-certified manufacturers, for example, adhere to global standards, ensuring that every drum is produced with precision and reliability. This certification serves as a testament to the quality and durability of the conveyor drums, fostering trust among clients and stakeholders. The industrial sector requires more than just standard solutions; it demands products backed by expertise and real-world testing. Engaging with a manufacturer that offers customization options can be a strategic advantage. Tailored drum designs that meet specific industrial demands not only optimize the existing infrastructure but also provide a competitive edge by addressing particular challenges unique to each operation. Looking ahead, the evolving landscape of conveyor drum technology is poised to incorporate greater automation and even more sustainable practices. As the industry embraces advancements in material science and AI, conveyor drums will likely become even more efficient and reliable, contributing to a significant reduction in operational costs and environmental impact. In summary, grasping the role and significance of conveyor drums in contemporary industrial applications necessitates expertise and experience. Their proper selection, maintenance, and integration with smart technologies can transform a production facility's efficiency, ensuring that it remains competitive in an increasingly demanding market. My professional journey reaffirms the importance of continuous innovation and adherence to high standards, solidifying the conveyor drum as an indispensable asset in any advanced industrial operation.

Furthermore, the advent of eco-friendly conveyor drum solutions has revolutionized the industry. Drums crafted from recycled materials are not only sustainable but also come with enhanced properties such as reduced weight and improved energy efficiency. The shift towards greener practices echoes an industry-wide commitment to environmental stewardship, marking a turning point in how conveyor systems are viewed in the context of sustainability. Trustworthy and reliable conveyor drum suppliers distinguish themselves through rigorous quality control and certification processes. ISO-certified manufacturers, for example, adhere to global standards, ensuring that every drum is produced with precision and reliability. This certification serves as a testament to the quality and durability of the conveyor drums, fostering trust among clients and stakeholders. The industrial sector requires more than just standard solutions; it demands products backed by expertise and real-world testing. Engaging with a manufacturer that offers customization options can be a strategic advantage. Tailored drum designs that meet specific industrial demands not only optimize the existing infrastructure but also provide a competitive edge by addressing particular challenges unique to each operation. Looking ahead, the evolving landscape of conveyor drum technology is poised to incorporate greater automation and even more sustainable practices. As the industry embraces advancements in material science and AI, conveyor drums will likely become even more efficient and reliable, contributing to a significant reduction in operational costs and environmental impact. In summary, grasping the role and significance of conveyor drums in contemporary industrial applications necessitates expertise and experience. Their proper selection, maintenance, and integration with smart technologies can transform a production facility's efficiency, ensuring that it remains competitive in an increasingly demanding market. My professional journey reaffirms the importance of continuous innovation and adherence to high standards, solidifying the conveyor drum as an indispensable asset in any advanced industrial operation.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS