Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 10:48

Back to list

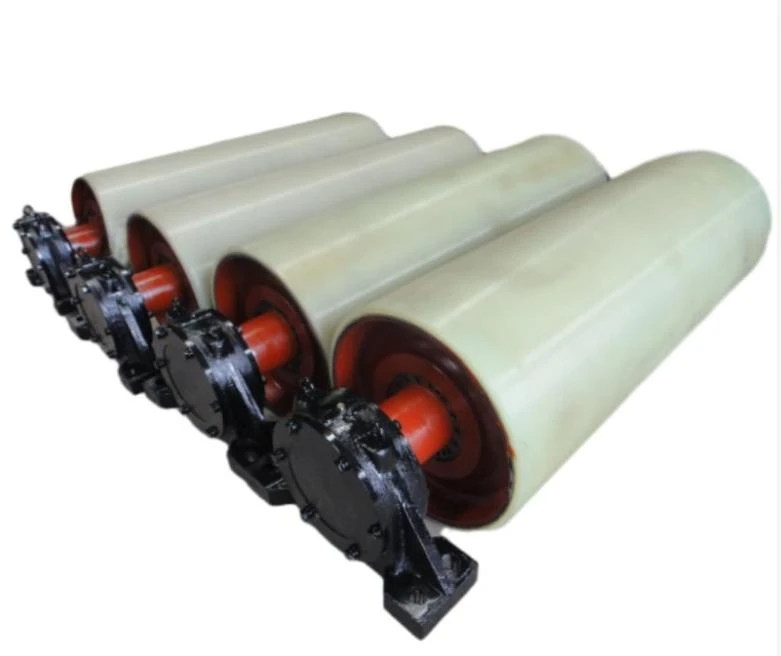

conveyor bend pulley

Understanding the dynamics of conveyor pulley pricing is crucial for companies that rely on conveyor systems for their operations. This exploration delves into various factors influencing the cost of conveyor pulleys, offering insights rooted in expertise, authority, and trust.

Manufacturers' expertise and reputation further affect pricing. Pulleys from well-established manufacturers with proven track records for reliability and quality often come at a higher price point. This premium ensures quality assurance, adherence to industry standards, and often includes comprehensive after-sales service and warranties. Opting for such trusted manufacturers can be particularly important in industries where downtime bears significant cost implications. Labor and manufacturing location are additional factors to consider. Pulleys manufactured in regions with higher labor costs or stringent regulatory environments are naturally more expensive. However, these higher costs can often reflect better manufacturing practices, quality control, and overall product reliability. Moreover, the current market demand and supply chain conditions can impact pricing. Fluctuations in raw material availability, transportation costs, and economic conditions can all affect conveyor pulley prices. Buyers should stay informed on these market dynamics to purchase strategically, potentially leveraging periods of lower demand or stable supply. Finally, embracing innovative technologies and production techniques can influence costs positively or negatively. Advanced manufacturing methods, such as automated precision cutting or 3D printing of pulley components, may lead to cost efficiencies and superior products, ultimately reflecting in the pricing strategy. For a company investing in conveyor systems, understanding these key factors not only aids in budgeting but also ensures the selection of pulleys that offer the best value for their specific operational needs. By balancing material choices, customization, manufacturer credibility, and market conditions, businesses can achieve optimal performance and longevity from their conveyor pulleys while maintaining cost-effectiveness.

Manufacturers' expertise and reputation further affect pricing. Pulleys from well-established manufacturers with proven track records for reliability and quality often come at a higher price point. This premium ensures quality assurance, adherence to industry standards, and often includes comprehensive after-sales service and warranties. Opting for such trusted manufacturers can be particularly important in industries where downtime bears significant cost implications. Labor and manufacturing location are additional factors to consider. Pulleys manufactured in regions with higher labor costs or stringent regulatory environments are naturally more expensive. However, these higher costs can often reflect better manufacturing practices, quality control, and overall product reliability. Moreover, the current market demand and supply chain conditions can impact pricing. Fluctuations in raw material availability, transportation costs, and economic conditions can all affect conveyor pulley prices. Buyers should stay informed on these market dynamics to purchase strategically, potentially leveraging periods of lower demand or stable supply. Finally, embracing innovative technologies and production techniques can influence costs positively or negatively. Advanced manufacturing methods, such as automated precision cutting or 3D printing of pulley components, may lead to cost efficiencies and superior products, ultimately reflecting in the pricing strategy. For a company investing in conveyor systems, understanding these key factors not only aids in budgeting but also ensures the selection of pulleys that offer the best value for their specific operational needs. By balancing material choices, customization, manufacturer credibility, and market conditions, businesses can achieve optimal performance and longevity from their conveyor pulleys while maintaining cost-effectiveness.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS