Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 10:45

Back to list

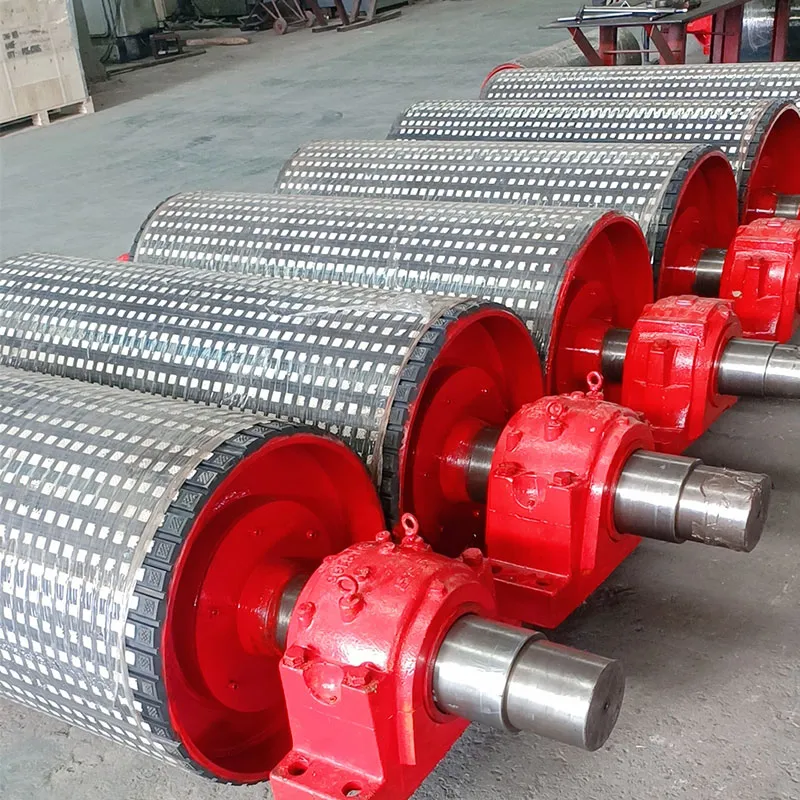

conveyor pulley components

In the intricate world of conveyor systems, each component plays a pivotal role in ensuring efficiency, durability, and productivity. Among these components, the conveyor pulley stands out as an essential element that demands attention to detail, expertise in design, and reliable construction. Understanding conveyor pulley components is crucial for professionals seeking to optimize their conveyor systems for various industrial applications.

For those seeking expertise in conveyor pulley components, leveraging advanced technologies and materials ensures high performance and longevity. Computational simulations allow professionals to predict wear and optimize design, aligning with modern industry standards. Collaboration with manufacturers who prioritize precision engineering and rigorous quality control can enhance the reliability of these systems. Furthermore, real-world experience and insights from industry experts greatly contribute towards optimizing conveyor pulley selection and maintenance practices. Engaging with communities and forums within the industry can provide invaluable knowledge, helping operators make informed decisions that balance cost, efficiency, and durability. Trust in the conveyor pulley system is built through consistent product quality, adherence to industry standards, and an ongoing commitment to innovation and improvement. As technology progresses, the integration of smart sensors and IoT capabilities allows for real-time monitoring of pulley performance, predictive maintenance, and increased safety measures. To navigate the complexities of conveyor pulley systems, it's critical to partner with suppliers who not only provide top-tier products but also offer comprehensive support, ensuring that components meet the unique needs of each application. Such collaboration builds a foundation of trust and establishes a pathway toward optimized operational efficiency, ensuring that the conveyor systems continue to drive industrial productivity into the future. In conclusion, understanding and investing in high-quality conveyor pulley components are integral for any industrial setup. The synergy of well-engineered drums, shafts, bearings, lagging, and seals ensures that conveyor systems operate at peak performance over their lifetime, ultimately leading to a competitive edge in manufacturing and processing sectors.

For those seeking expertise in conveyor pulley components, leveraging advanced technologies and materials ensures high performance and longevity. Computational simulations allow professionals to predict wear and optimize design, aligning with modern industry standards. Collaboration with manufacturers who prioritize precision engineering and rigorous quality control can enhance the reliability of these systems. Furthermore, real-world experience and insights from industry experts greatly contribute towards optimizing conveyor pulley selection and maintenance practices. Engaging with communities and forums within the industry can provide invaluable knowledge, helping operators make informed decisions that balance cost, efficiency, and durability. Trust in the conveyor pulley system is built through consistent product quality, adherence to industry standards, and an ongoing commitment to innovation and improvement. As technology progresses, the integration of smart sensors and IoT capabilities allows for real-time monitoring of pulley performance, predictive maintenance, and increased safety measures. To navigate the complexities of conveyor pulley systems, it's critical to partner with suppliers who not only provide top-tier products but also offer comprehensive support, ensuring that components meet the unique needs of each application. Such collaboration builds a foundation of trust and establishes a pathway toward optimized operational efficiency, ensuring that the conveyor systems continue to drive industrial productivity into the future. In conclusion, understanding and investing in high-quality conveyor pulley components are integral for any industrial setup. The synergy of well-engineered drums, shafts, bearings, lagging, and seals ensures that conveyor systems operate at peak performance over their lifetime, ultimately leading to a competitive edge in manufacturing and processing sectors.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS