Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 13, 2025 08:31

Back to list

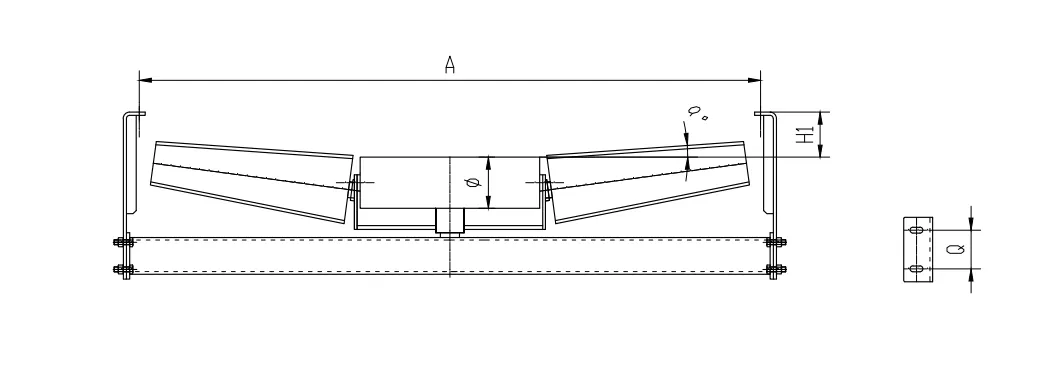

Belt Conveyor Idler

Rollers and idlers are indispensable components in the conveyor systems used across various industries, from mining and manufacturing to logistics and packaging. Designing a conveyor system requires careful consideration of these elements to ensure seamless operation, efficiency, and durability. This article delves into the intricate world of rollers and idlers, offering insights gained from years of experience, authoritative know-how, and industry best practices to guide you in selecting the optimal components for your needs.

Maintenance is Key Even the best-engineered systems require regular maintenance to sustain performance and prevent downtime. Routine inspections of rollers and idlers can identify premature wear, ensuring timely replacements before system performance is compromised. Many modern solutions include self-cleaning features that reduce maintenance frequency, while others allow for quick-access mechanisms that simplify on-site repairs. Industry Insights and Best Practices Long-standing industry expertise emphasizes the importance of aligning components with operational demands. Mining applications, for example, require heavy-duty rollers and idlers capable of handling abrasive materials and heavy loads. Conversely, lightweight applications in e-commerce distribution centers benefit from low-friction, noise-reducing components that maintain high speed and efficiency. Furthermore, a shift towards smart conveyor systems has introduced innovations like sensor-equipped rollers and idlers. These components provide real-time data on system performance, enabling predictive maintenance strategies that further enhance reliability and efficiency. The Trust Factor Choosing the Right Supplier Selecting a reliable supplier for rollers and idlers adds another layer of assurance in system performance. Look for manufacturers with a proven track record, industry certifications, and a commitment to innovation. Partnering with experts provides access to the latest advancements and ensures that your system remains at the forefront of technology and efficiency. Conclusion With decades of collective experience in the field, our perspective on rollers and idlers offers a comprehensive understanding of these pivotal elements in conveyor systems. Their roles, material choices, and design considerations are crucial for system efficiency and longevity. Emphasizing maintenance, adopting best practices, and partnering with reputable suppliers solidify the foundation for a robust and reliable conveyor solution tailored to your operational needs.

Maintenance is Key Even the best-engineered systems require regular maintenance to sustain performance and prevent downtime. Routine inspections of rollers and idlers can identify premature wear, ensuring timely replacements before system performance is compromised. Many modern solutions include self-cleaning features that reduce maintenance frequency, while others allow for quick-access mechanisms that simplify on-site repairs. Industry Insights and Best Practices Long-standing industry expertise emphasizes the importance of aligning components with operational demands. Mining applications, for example, require heavy-duty rollers and idlers capable of handling abrasive materials and heavy loads. Conversely, lightweight applications in e-commerce distribution centers benefit from low-friction, noise-reducing components that maintain high speed and efficiency. Furthermore, a shift towards smart conveyor systems has introduced innovations like sensor-equipped rollers and idlers. These components provide real-time data on system performance, enabling predictive maintenance strategies that further enhance reliability and efficiency. The Trust Factor Choosing the Right Supplier Selecting a reliable supplier for rollers and idlers adds another layer of assurance in system performance. Look for manufacturers with a proven track record, industry certifications, and a commitment to innovation. Partnering with experts provides access to the latest advancements and ensures that your system remains at the forefront of technology and efficiency. Conclusion With decades of collective experience in the field, our perspective on rollers and idlers offers a comprehensive understanding of these pivotal elements in conveyor systems. Their roles, material choices, and design considerations are crucial for system efficiency and longevity. Emphasizing maintenance, adopting best practices, and partnering with reputable suppliers solidify the foundation for a robust and reliable conveyor solution tailored to your operational needs.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS