Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 13, 2025 08:04

Back to list

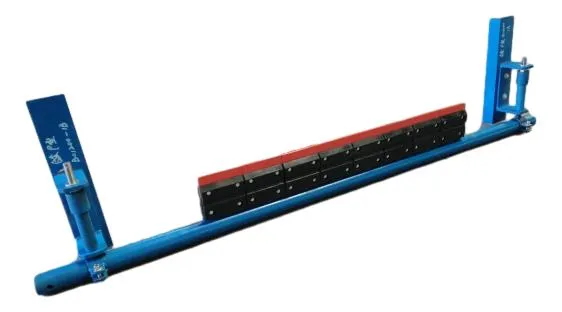

Belt Conveyor Idler

Idler conveyor rollers serve as essential components in numerous industrial applications, fulfilling an indispensable role in material handling and conveying systems. Their significance lies not only in their functionality but also in how expertly they are integrated into these systems to optimize performance and efficiency. This article delves into the experience, expertise, authoritativeness, and trustworthiness centered around idler conveyor rollers, underlining why they are a pivotal element in modern industrial operations.

Trustworthy Vendors and Suppliers Selecting idler conveyor rollers from reputable vendors and manufacturers is crucial. Trustworthiness in the supply chain ensures that businesses obtain high-quality components that conform to industry standards and regulations. Trusted suppliers offer comprehensive warranties and are transparent about their manufacturing processes. They may also provide certifications related to material quality and environmental compliance, which are critical in industries where operational integrity and safety are paramount. Advanced Technologies and Innovations Emerging technologies are transforming the landscape of conveyor systems, and idler rollers are no exception. Innovations such as predictive maintenance technologies use sensors and IoT to monitor the conditions and performance of idler rollers in real-time. These advancements enable companies to preemptively address maintenance needs, reducing the likelihood of unexpected failures and optimizing resource allocation. Another notable innovation is the development of energy-efficient rollers designed to minimize power usage while maintaining high performance levels. These energy-saving solutions are increasingly in demand as industries strive to reduce their carbon footprint and operational costs. Conclusive Insights Incorporating quality idler conveyor rollers into material handling systems is a testament to both technical proficiency and strategic vision. Their influence extends beyond mere transport facilitation to significantly impacting operational efficiency, longevity, and overall system reliability. For businesses aiming to achieve both sustainable growth and operational excellence, investing in the right idler conveyor rollers, along with deploying skilled expertise in their installation and maintenance, is a proven strategy. Ultimately, idler conveyor rollers embody a blend of engineering acumen, technical insight, and reliable manufacturing, underpinning the productivity of today's industrial operations. Their critical role substantiates why acquiring and maintaining the right rollers is a decision with far-reaching implications for efficiency and success in industrial material handling systems.

Trustworthy Vendors and Suppliers Selecting idler conveyor rollers from reputable vendors and manufacturers is crucial. Trustworthiness in the supply chain ensures that businesses obtain high-quality components that conform to industry standards and regulations. Trusted suppliers offer comprehensive warranties and are transparent about their manufacturing processes. They may also provide certifications related to material quality and environmental compliance, which are critical in industries where operational integrity and safety are paramount. Advanced Technologies and Innovations Emerging technologies are transforming the landscape of conveyor systems, and idler rollers are no exception. Innovations such as predictive maintenance technologies use sensors and IoT to monitor the conditions and performance of idler rollers in real-time. These advancements enable companies to preemptively address maintenance needs, reducing the likelihood of unexpected failures and optimizing resource allocation. Another notable innovation is the development of energy-efficient rollers designed to minimize power usage while maintaining high performance levels. These energy-saving solutions are increasingly in demand as industries strive to reduce their carbon footprint and operational costs. Conclusive Insights Incorporating quality idler conveyor rollers into material handling systems is a testament to both technical proficiency and strategic vision. Their influence extends beyond mere transport facilitation to significantly impacting operational efficiency, longevity, and overall system reliability. For businesses aiming to achieve both sustainable growth and operational excellence, investing in the right idler conveyor rollers, along with deploying skilled expertise in their installation and maintenance, is a proven strategy. Ultimately, idler conveyor rollers embody a blend of engineering acumen, technical insight, and reliable manufacturing, underpinning the productivity of today's industrial operations. Their critical role substantiates why acquiring and maintaining the right rollers is a decision with far-reaching implications for efficiency and success in industrial material handling systems.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS