Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 13:41

Back to list

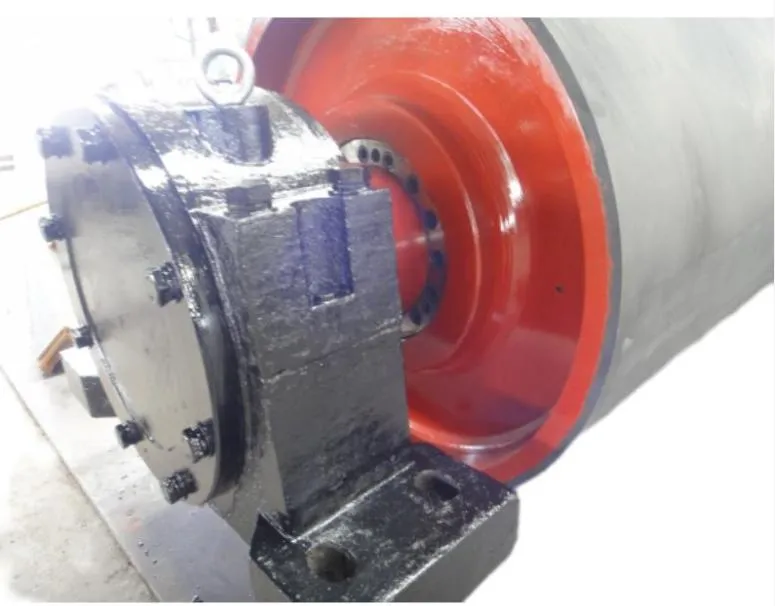

pulley lagging rubber

Rubber pulley lagging is a critical component in the conveyor belt systems that industries worldwide rely on for efficient material handling. As industries continuously seek ways to minimize costs and improve operational efficiency, understanding the role, importance, and selection of pulley lagging rubber becomes imperative.

Authoritativeness takes form in the adherence to stringent industrial standards and best practices. Reputable manufacturers of pulley lagging rubber ensure their products comply with global standards such as ISO and DIN, offering assurance about the durability and efficiency of the rubber materials used. Furthermore, partnering with manufacturers who provide comprehensive technical support and customization options can be incredibly beneficial, as they help tailor solutions that precisely match the specific requirements of an operation. Trustworthiness is a cornerstone of product efficacy, with the credibility of rubber lagging largely dependent on the reputation of the supplier and the results of third-party testing. Consumer reviews and testimonials play a vital role in affirming the reliability of a product. Many industries have stressed the importance of choosing suppliers with a proven track record of consistent quality and dependable customer service. A robust warranty and service package also contribute significantly to the trustworthiness of the product, ensuring customers can rely on solutions to withstand the rigors of demanding operational conditions. In conclusion, the strategic application of pulley lagging rubber in conveyor systems offers substantial benefits by boosting efficiency, reducing slippage, and cutting down maintenance costs. Carefully considering factors such as material choice, pattern design, compliance with standards, and supplier reliability will inform better decision-making. Leveraging proven solutions can significantly enhance industrial operations, providing a competitive edge in an ever-demanding market. As the industry continues to evolve, the necessity for expertly informed decisions regarding components like rubber pulley lagging will only grow more essential, underscoring the importance of staying abreast with the latest technological developments and industry standards.

Authoritativeness takes form in the adherence to stringent industrial standards and best practices. Reputable manufacturers of pulley lagging rubber ensure their products comply with global standards such as ISO and DIN, offering assurance about the durability and efficiency of the rubber materials used. Furthermore, partnering with manufacturers who provide comprehensive technical support and customization options can be incredibly beneficial, as they help tailor solutions that precisely match the specific requirements of an operation. Trustworthiness is a cornerstone of product efficacy, with the credibility of rubber lagging largely dependent on the reputation of the supplier and the results of third-party testing. Consumer reviews and testimonials play a vital role in affirming the reliability of a product. Many industries have stressed the importance of choosing suppliers with a proven track record of consistent quality and dependable customer service. A robust warranty and service package also contribute significantly to the trustworthiness of the product, ensuring customers can rely on solutions to withstand the rigors of demanding operational conditions. In conclusion, the strategic application of pulley lagging rubber in conveyor systems offers substantial benefits by boosting efficiency, reducing slippage, and cutting down maintenance costs. Carefully considering factors such as material choice, pattern design, compliance with standards, and supplier reliability will inform better decision-making. Leveraging proven solutions can significantly enhance industrial operations, providing a competitive edge in an ever-demanding market. As the industry continues to evolve, the necessity for expertly informed decisions regarding components like rubber pulley lagging will only grow more essential, underscoring the importance of staying abreast with the latest technological developments and industry standards.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS