Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 10:25

Back to list

Polyurethane Pulley(Polyurethane Lagging Pulley)

The conveyor drum pulley is a pivotal component in material handling systems, renowned for its expertise in streamlining conveyance processes across numerous industrial sectors. Drawing from years of insightful experience and in-depth technical knowledge, the importance of selecting the right drum pulley emerges as paramount for operational efficiency and performance reliability.

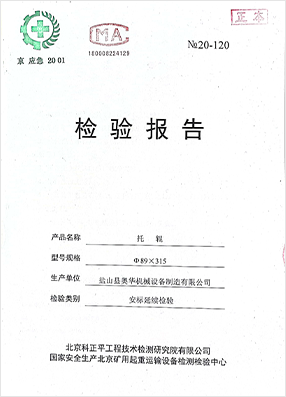

When it comes to trustworthiness, a company's reputation can hinge on the continuous functionality of its conveyor systems. Therefore, engaging with trusted manufacturers and suppliers who have a proven track record and certifications in quality management can provide peace of mind. Companies specializing in conveyor components with ISO certifications often reflect a commitment to high standards, ensuring each pulley meets rigorous testing and safety reviews. Selecting the right conveyor drum pulley involves considering factors such as diameter, face width, and shaft diameter, alongside environmental considerations like temperature, humidity, and exposure to chemicals. Moreover, it's crucial to consider the type of pulleys needed, such as drive pulleys, which are responsible for driving the belt, or tail pulleys, which provide tension and tracking. Customers' experience is greatly enriched when they opt for products from established leaders in the industry, known for their innovative designs and technical counsel. Personalized solutions that include custom engineering and delivery precision cater to the unique demands of various sectors, further cementing the client's trust and satisfaction with their chosen manufacturer or supplier. In conclusion, the knowledge and experience embedded in the domain of conveyor drum pulleys illustrate their vital role in the seamless operation of conveyor systems across industries. With the exploration of new materials and technological advancements, these components continue to evolve, promising higher efficiencies and longer life cycles. By prioritizing expertise, authoritativeness, and trust in this field, businesses can ensure their material handling processes are not only efficient but also reliable and sustainable in the long term.

When it comes to trustworthiness, a company's reputation can hinge on the continuous functionality of its conveyor systems. Therefore, engaging with trusted manufacturers and suppliers who have a proven track record and certifications in quality management can provide peace of mind. Companies specializing in conveyor components with ISO certifications often reflect a commitment to high standards, ensuring each pulley meets rigorous testing and safety reviews. Selecting the right conveyor drum pulley involves considering factors such as diameter, face width, and shaft diameter, alongside environmental considerations like temperature, humidity, and exposure to chemicals. Moreover, it's crucial to consider the type of pulleys needed, such as drive pulleys, which are responsible for driving the belt, or tail pulleys, which provide tension and tracking. Customers' experience is greatly enriched when they opt for products from established leaders in the industry, known for their innovative designs and technical counsel. Personalized solutions that include custom engineering and delivery precision cater to the unique demands of various sectors, further cementing the client's trust and satisfaction with their chosen manufacturer or supplier. In conclusion, the knowledge and experience embedded in the domain of conveyor drum pulleys illustrate their vital role in the seamless operation of conveyor systems across industries. With the exploration of new materials and technological advancements, these components continue to evolve, promising higher efficiencies and longer life cycles. By prioritizing expertise, authoritativeness, and trust in this field, businesses can ensure their material handling processes are not only efficient but also reliable and sustainable in the long term.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS