Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 10:23

Back to list

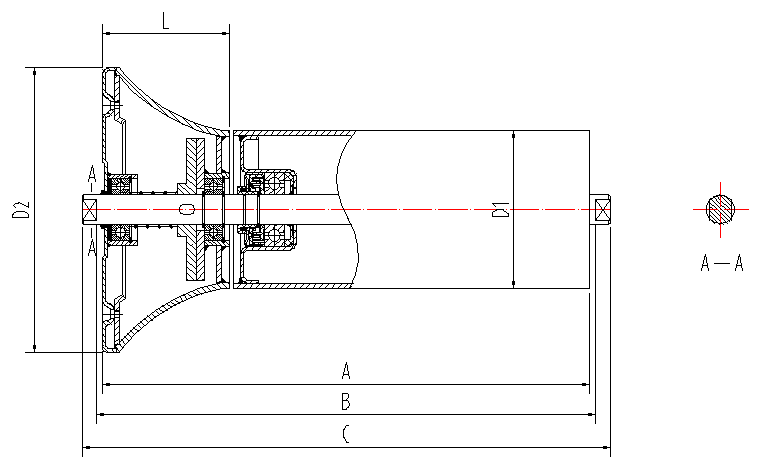

Slagging Pulley(Heavy Duty)

In the fast-evolving world of industrial conveyor systems, ensuring efficient operation is paramount. One crucial component in this system is the conveyor pulley lagging. A specialized booklet overlay applied to the shell of a conveyor pulley, lagging is designed to enhance frictional contact between the pulley and the conveyor belt. This optimized friction is essential, preventing belt slippage and increasing traction, leading to improved energy efficiency and lifespan of the conveyor system.

Trust and reliability in conveyor pulley lagging are built over time, established through consistent performance and adherence to industry standards. Reputable manufacturers uphold rigorous quality control measures, providing warranties that affirm their confidence in the durability of their products. Businesses are encouraged to partner with established suppliers who can offer not just quality products but also technical support throughout the lifespan of the conveyor systems. The marketplace for conveyor pulley lagging continues to innovate, driven by an ever-present demand for higher efficiency and lower maintenance costs. Emerging innovations include hybrid materials that combine the elasticity of rubber with the resilience of ceramics or polyurethane, leading to even longer-lasting lagging solutions. Additionally, modern developments in adhesive technologies promise easier installations and enhanced bonding strength, reducing the likelihood of detachment over time. In conclusion, the domain of conveyor pulley lagging is characterized by evolving technologies and material advancements that cater to a wide range of industrial needs. As these innovations progress, leveraging the expertise of professionals in selecting, installing, and maintaining these systems becomes increasingly vital. Only through such an integrative approach—combining material knowledge, design precision, and reliable partnerships—can industries truly capitalize on the full potential of their conveyor systems.

Trust and reliability in conveyor pulley lagging are built over time, established through consistent performance and adherence to industry standards. Reputable manufacturers uphold rigorous quality control measures, providing warranties that affirm their confidence in the durability of their products. Businesses are encouraged to partner with established suppliers who can offer not just quality products but also technical support throughout the lifespan of the conveyor systems. The marketplace for conveyor pulley lagging continues to innovate, driven by an ever-present demand for higher efficiency and lower maintenance costs. Emerging innovations include hybrid materials that combine the elasticity of rubber with the resilience of ceramics or polyurethane, leading to even longer-lasting lagging solutions. Additionally, modern developments in adhesive technologies promise easier installations and enhanced bonding strength, reducing the likelihood of detachment over time. In conclusion, the domain of conveyor pulley lagging is characterized by evolving technologies and material advancements that cater to a wide range of industrial needs. As these innovations progress, leveraging the expertise of professionals in selecting, installing, and maintaining these systems becomes increasingly vital. Only through such an integrative approach—combining material knowledge, design precision, and reliable partnerships—can industries truly capitalize on the full potential of their conveyor systems.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS