Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 16:52

Back to list

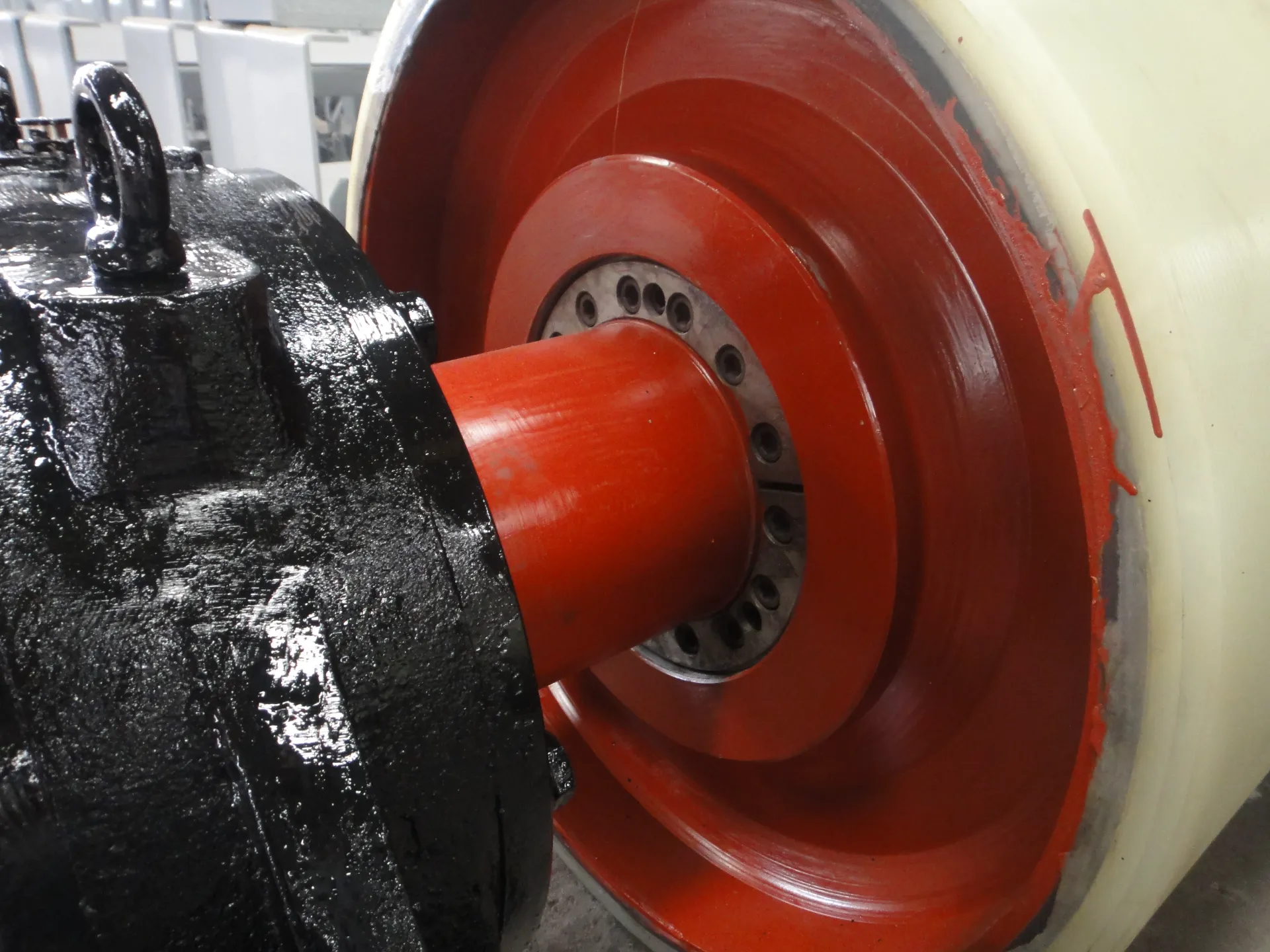

Polyurethane Pulley(Polyurethane Lagging Pulley)

Polyurethane pulleys are becoming pivotal components in various industrial applications due to their unique properties and exceptional performance. These components, crafted from high-quality polyurethane, offer a range of benefits that not only enhance the efficiency of machinery but also significantly decrease maintenance demands.

Moreover, the noise reduction characteristic of polyurethane pulleys cannot be overstated. In operations where machinery noise is a concern, such as in medical equipment or precision crafting, the use of polyurethane pulleys can lead to a quieter and more pleasant working environment. This noise reduction is primarily due to the material's ability to dampen sound, contributing to better workplace conditions and compliance with noise regulations. In terms of trustworthiness and credibility, polyurethane pulleys represent a well-established solution backed by extensive research and development. Industries relying on these components often report enhanced operational reliability and improved machine lifespan. The consistent performance of polyurethane pulleys underpins their reputation for quality, making them a preferred choice for engineers and manufacturers alike. Furthermore, the environmental impact of using polyurethane pulleys is considerably lower than many alternative materials. Polyurethane is more environmentally friendly due to its longer lifespan and less frequent need for replacement, which translates into less waste. Additionally, advancements in manufacturing techniques have made it possible to produce polyurethane pulleys with decreased ecological footprints, aligning with contemporary sustainability goals. In conclusion, polyurethane pulleys deliver a blend of robustness, versatility, and efficiency that is unmatched by traditional materials. Their suitability across a wide array of applications, coupled with their customization capabilities and eco-friendly profile, make them an indispensable component in modern engineering. As industries continue to evolve, the demand for reliable, durable, and high-performance solutions like polyurethane pulleys is likely to grow, substantiating their essential role in contemporary and future industrial landscapes.

Moreover, the noise reduction characteristic of polyurethane pulleys cannot be overstated. In operations where machinery noise is a concern, such as in medical equipment or precision crafting, the use of polyurethane pulleys can lead to a quieter and more pleasant working environment. This noise reduction is primarily due to the material's ability to dampen sound, contributing to better workplace conditions and compliance with noise regulations. In terms of trustworthiness and credibility, polyurethane pulleys represent a well-established solution backed by extensive research and development. Industries relying on these components often report enhanced operational reliability and improved machine lifespan. The consistent performance of polyurethane pulleys underpins their reputation for quality, making them a preferred choice for engineers and manufacturers alike. Furthermore, the environmental impact of using polyurethane pulleys is considerably lower than many alternative materials. Polyurethane is more environmentally friendly due to its longer lifespan and less frequent need for replacement, which translates into less waste. Additionally, advancements in manufacturing techniques have made it possible to produce polyurethane pulleys with decreased ecological footprints, aligning with contemporary sustainability goals. In conclusion, polyurethane pulleys deliver a blend of robustness, versatility, and efficiency that is unmatched by traditional materials. Their suitability across a wide array of applications, coupled with their customization capabilities and eco-friendly profile, make them an indispensable component in modern engineering. As industries continue to evolve, the demand for reliable, durable, and high-performance solutions like polyurethane pulleys is likely to grow, substantiating their essential role in contemporary and future industrial landscapes.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS