Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 16:27

Back to list

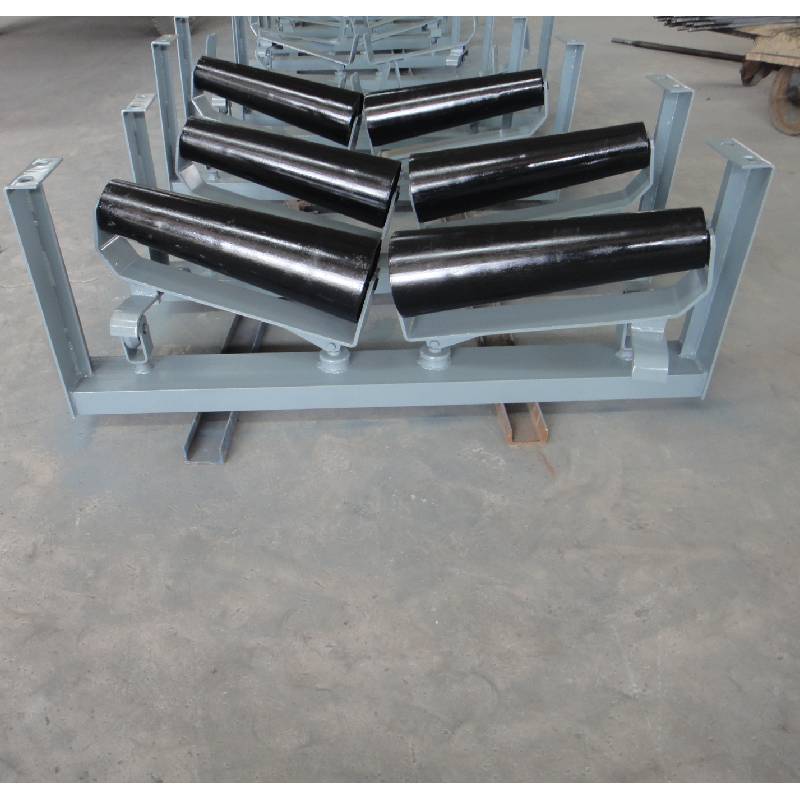

Rubber Lagging Pulley

When considering the essential components of mechanical power transmission, the rubber belt pulley stands out as a vital element that ensures efficiency and longevity in various applications. As a crucial interface that connects the belt to the machinery, the choice of a rubber belt pulley can greatly influence performance, noise reduction, and operational durability.

Expertise in the selection and maintenance of rubber belt pulleys involves understanding both the mechanics and the material science behind them. Regular inspections for signs of wear, such as cracks or fraying, can prevent unexpected failures. Employing diagnostic tools to monitor vibration and alignment also ensures that the pulley system remains within optimal operational parameters. Authoritativeness in the context of rubber belt pulleys involves staying informed about the latest technological advancements and material innovations. Industry leaders often participate in developing standards and guidelines, contributing valuable insights based on field data and empirical research. Trustworthiness is reinforced through established industry certifications and compliance with rigorous testing protocols, ensuring that the pulleys provided to customers are of the highest quality. It's worth noting that in environments where noise reduction is a priority, rubber belt pulleys are particularly advantageous. The material's inherent damping properties can significantly decrease noise levels, which is especially beneficial in settings sensitive to sound disturbances, such as in office machinery or residential HVAC systems. In conclusion, the utilization of rubber belt pulleys in mechanical systems brings about numerous benefits, including improved efficiency, reduced maintenance costs, and extended equipment lifespan. Their design, tailored to resist a variety of environmental stresses, aligns with the best practices in mechanical engineering. By focusing on material quality, customizing solutions to fit specific operational needs, and adhering to rigorous testing standards, rubber belt pulleys prove to be indispensable components in the drive towards operational excellence.

Expertise in the selection and maintenance of rubber belt pulleys involves understanding both the mechanics and the material science behind them. Regular inspections for signs of wear, such as cracks or fraying, can prevent unexpected failures. Employing diagnostic tools to monitor vibration and alignment also ensures that the pulley system remains within optimal operational parameters. Authoritativeness in the context of rubber belt pulleys involves staying informed about the latest technological advancements and material innovations. Industry leaders often participate in developing standards and guidelines, contributing valuable insights based on field data and empirical research. Trustworthiness is reinforced through established industry certifications and compliance with rigorous testing protocols, ensuring that the pulleys provided to customers are of the highest quality. It's worth noting that in environments where noise reduction is a priority, rubber belt pulleys are particularly advantageous. The material's inherent damping properties can significantly decrease noise levels, which is especially beneficial in settings sensitive to sound disturbances, such as in office machinery or residential HVAC systems. In conclusion, the utilization of rubber belt pulleys in mechanical systems brings about numerous benefits, including improved efficiency, reduced maintenance costs, and extended equipment lifespan. Their design, tailored to resist a variety of environmental stresses, aligns with the best practices in mechanical engineering. By focusing on material quality, customizing solutions to fit specific operational needs, and adhering to rigorous testing standards, rubber belt pulleys prove to be indispensable components in the drive towards operational excellence.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS