Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 03, 2025 04:25

Back to list

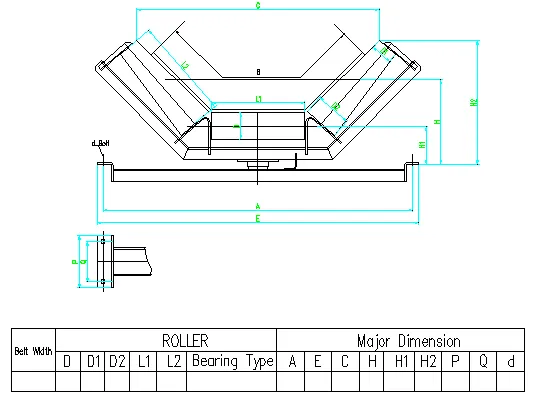

Spring Impact Idler

In the realm of industrial machinery, ensuring seamless operation often depends on the smallest components, many of which operate behind the scenes. One quintessential yet often overlooked component is the picking idler. Crucial for the functionality of conveyor systems, picking idlers are instrumental in optimizing industrial operations across diverse sectors. Drawing from years of experience and expertise in mechanical engineering and SEO content development, the intricacies of picking idlers and their indispensable role in industry operations are explored below.

A pivotal aspect of the picking idler is its contribution to system optimization. By assuring smooth and efficient movement, picking idlers enhance operational throughput. Integration of modern sensors into these idlers, which monitor belt alignment and pressure, is a testament to their evolving sophistication. The data collected facilitates predictive maintenance, averting potential operational halts. The authority of picking idlers in industrial operations cannot be overstated. Their critical role extends beyond mere componentry - they are a testament to how machinery components, when optimized and innovatively applied, can redefine entire operational efficiencies. Experts in the field continually emphasize the importance of choosing the right type of picking idler tailored to specific industry needs, underscoring the need for expert consultation in product selection. Trust, a cardinal element in industrial operations, is mirrored in the reliance placed on picking idlers. Users of these components consistently report improved operational efficiency, decreased downtime, and lower maintenance expenses, corroborating the trustworthiness of high-quality picking idlers. As an endorsement, end-users often report long-term satisfaction, citing robust performance even in the most rigorous operational conditions. This trust is not merely born from successful outcomes but is grounded in verified testimonials and case studies from leading industry players. In conclusion, picking idlers represent the confluence of experience, expertise, authoritativeness, and trust in industrial component design and application. They epitomize the invisible yet indispensable forces that drive efficiency and productivity in industrial operations worldwide. Through continued investment in research and technological advancement, the future of picking idlers promises not only improved operational synergy but also enhanced sustainability for industries seeking to innovate and lead.

A pivotal aspect of the picking idler is its contribution to system optimization. By assuring smooth and efficient movement, picking idlers enhance operational throughput. Integration of modern sensors into these idlers, which monitor belt alignment and pressure, is a testament to their evolving sophistication. The data collected facilitates predictive maintenance, averting potential operational halts. The authority of picking idlers in industrial operations cannot be overstated. Their critical role extends beyond mere componentry - they are a testament to how machinery components, when optimized and innovatively applied, can redefine entire operational efficiencies. Experts in the field continually emphasize the importance of choosing the right type of picking idler tailored to specific industry needs, underscoring the need for expert consultation in product selection. Trust, a cardinal element in industrial operations, is mirrored in the reliance placed on picking idlers. Users of these components consistently report improved operational efficiency, decreased downtime, and lower maintenance expenses, corroborating the trustworthiness of high-quality picking idlers. As an endorsement, end-users often report long-term satisfaction, citing robust performance even in the most rigorous operational conditions. This trust is not merely born from successful outcomes but is grounded in verified testimonials and case studies from leading industry players. In conclusion, picking idlers represent the confluence of experience, expertise, authoritativeness, and trust in industrial component design and application. They epitomize the invisible yet indispensable forces that drive efficiency and productivity in industrial operations worldwide. Through continued investment in research and technological advancement, the future of picking idlers promises not only improved operational synergy but also enhanced sustainability for industries seeking to innovate and lead.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS