Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 19:24

Back to list

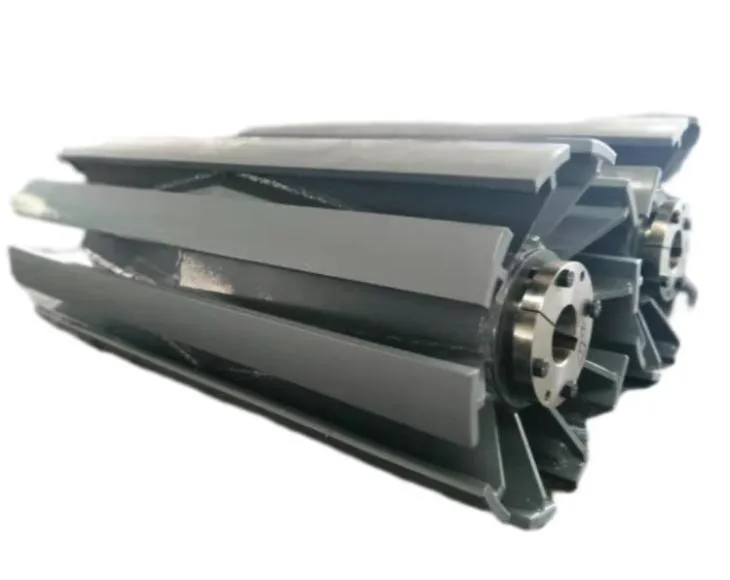

mining conveyor parts

In the highly competitive field of industrial operations, efficiency is king. The use of mining conveyor systems has revolutionized the industry, significantly improving the speed and efficiency with which materials are transported. When considering enhancements to your conveyor system, understanding the critical role of various mining conveyor parts is essential. Here, we delve into the essential components that every operator should consider to achieve peak operational efficiency, backed by decades-long industry experience, specialized knowledge, and with an emphasis on quality and safety.

Belt Cleaners and Scrapers Maintenance Facilitators Even with superior materials, debris, and material residues can impact performance if not managed properly. High-quality belt cleaners and scrapers ensure that unwanted materials are effectively removed, preventing material buildup which can lead to belt slippage or system failure. This enhances both operational efficiency and the safety of the work environment. A multi-faceted approach involving both torsion and spring tensioners can provide sustained cleaning pressure, ensuring no detail is overlooked. Safety Guards and Emergency Systems Protecting Your Assets Safety cannot be overstated in mining operations. Guard systems covering moving parts prevent accidental contact and injury, while emergency stop mechanisms provide immediate shutdown capabilities in situations demanding urgent response. Contemporary systems integrate remote monitoring and operational controls, enabling autonomous alerts and safety audits, thus reinforcing operational trust. Conveyor Monitoring Systems Data-Driven Performance In today's data-driven era, conveyor monitoring systems have equipped managers with the ability to preemptively address issues through continuous system diagnostics. By deploying sophisticated sensors and software analytics, these systems provide real-time insights into operational effectiveness, predictive maintenance, and potential performance liability. These empower operators with in-depth knowledge, facilitating data-rich decisions that uphold long-term productivity and reduce unexpected downtimes. With comprehensive understanding and strategic application, investing in superior mining conveyor parts guarantees not only enhanced operational efficiency and lifespan but also ensures safety and environmental responsibility. Drawing from profound experience and documenting case studies, companies can establish themselves as authoritative entities in industrial engineering, leveraging specialized insights to navigate complexities and scale new heights of operational excellence.

Belt Cleaners and Scrapers Maintenance Facilitators Even with superior materials, debris, and material residues can impact performance if not managed properly. High-quality belt cleaners and scrapers ensure that unwanted materials are effectively removed, preventing material buildup which can lead to belt slippage or system failure. This enhances both operational efficiency and the safety of the work environment. A multi-faceted approach involving both torsion and spring tensioners can provide sustained cleaning pressure, ensuring no detail is overlooked. Safety Guards and Emergency Systems Protecting Your Assets Safety cannot be overstated in mining operations. Guard systems covering moving parts prevent accidental contact and injury, while emergency stop mechanisms provide immediate shutdown capabilities in situations demanding urgent response. Contemporary systems integrate remote monitoring and operational controls, enabling autonomous alerts and safety audits, thus reinforcing operational trust. Conveyor Monitoring Systems Data-Driven Performance In today's data-driven era, conveyor monitoring systems have equipped managers with the ability to preemptively address issues through continuous system diagnostics. By deploying sophisticated sensors and software analytics, these systems provide real-time insights into operational effectiveness, predictive maintenance, and potential performance liability. These empower operators with in-depth knowledge, facilitating data-rich decisions that uphold long-term productivity and reduce unexpected downtimes. With comprehensive understanding and strategic application, investing in superior mining conveyor parts guarantees not only enhanced operational efficiency and lifespan but also ensures safety and environmental responsibility. Drawing from profound experience and documenting case studies, companies can establish themselves as authoritative entities in industrial engineering, leveraging specialized insights to navigate complexities and scale new heights of operational excellence.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS