Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 19:06

Back to list

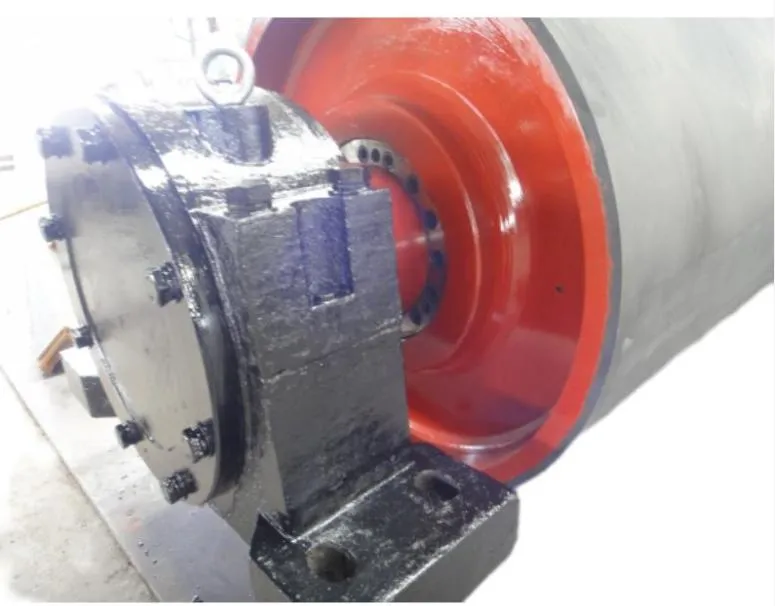

main parts of belt conveyor

A belt conveyor is a crucial component in various industries, renowned for its efficiency in transporting materials effortlessly over significant distances. Understanding the main parts of a belt conveyor is imperative for optimizing its use and ensuring the longevity of its components. This knowledge, rooted in experience and expertise, not only enhances productivity but also guarantees safety and reliability in operations.

An equally important component is the motor, usually an electric motor engineered to comply with the system’s load requirements. The motor must deliver consistent power to the drive pulley, ensuring smooth and continuous belt operation. Motors vary in size and horsepower based on specific conveyor applications. Professionalism in selecting and calibrating the motor is essential to adapt to load variations and enhance energy efficiency. To ensure the belt conveyor operates efficiently and safely, the incorporation of a control system is indispensable. The control system comprises programmable logic controllers (PLC), sensors, and other monitoring devices that enable automated operation and facilitate real-time monitoring. This system is crucial in industries that demand precision and high-speed material handling, allowing for adaptations to varying operational demands speedily and safely. Finally, the frame-mounted cleaning and safety systems—such as belt cleaners, skirting, and emergency stop systems—play a vital role in maintaining the conveyor system. Belt cleaners, for instance, remove residual material that might adhere to the belt, preventing buildup and reducing wear. Skirting minimizes spillage at transfer points, maintaining operational efficiency and environmental cleanliness. Trustworthiness in maintaining these systems enhances the safety and functional longevity of the belt conveyor. With an understanding rooted in both experience and expertise, recognizing the interplay between these main parts of belt conveyors underscores their importance in industrial applications. This not only maximizes operational efficacy but also fosters an environment of safety and reliability, consolidating the belt conveyor's position as an indispensable tool in modern industrial processes. In summation, the profound comprehension and meticulous maintenance of each component affirm the trustworthiness and authority of belt conveyors in various operational settings.

An equally important component is the motor, usually an electric motor engineered to comply with the system’s load requirements. The motor must deliver consistent power to the drive pulley, ensuring smooth and continuous belt operation. Motors vary in size and horsepower based on specific conveyor applications. Professionalism in selecting and calibrating the motor is essential to adapt to load variations and enhance energy efficiency. To ensure the belt conveyor operates efficiently and safely, the incorporation of a control system is indispensable. The control system comprises programmable logic controllers (PLC), sensors, and other monitoring devices that enable automated operation and facilitate real-time monitoring. This system is crucial in industries that demand precision and high-speed material handling, allowing for adaptations to varying operational demands speedily and safely. Finally, the frame-mounted cleaning and safety systems—such as belt cleaners, skirting, and emergency stop systems—play a vital role in maintaining the conveyor system. Belt cleaners, for instance, remove residual material that might adhere to the belt, preventing buildup and reducing wear. Skirting minimizes spillage at transfer points, maintaining operational efficiency and environmental cleanliness. Trustworthiness in maintaining these systems enhances the safety and functional longevity of the belt conveyor. With an understanding rooted in both experience and expertise, recognizing the interplay between these main parts of belt conveyors underscores their importance in industrial applications. This not only maximizes operational efficacy but also fosters an environment of safety and reliability, consolidating the belt conveyor's position as an indispensable tool in modern industrial processes. In summation, the profound comprehension and meticulous maintenance of each component affirm the trustworthiness and authority of belt conveyors in various operational settings.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS