Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 03, 2025 05:35

Back to list

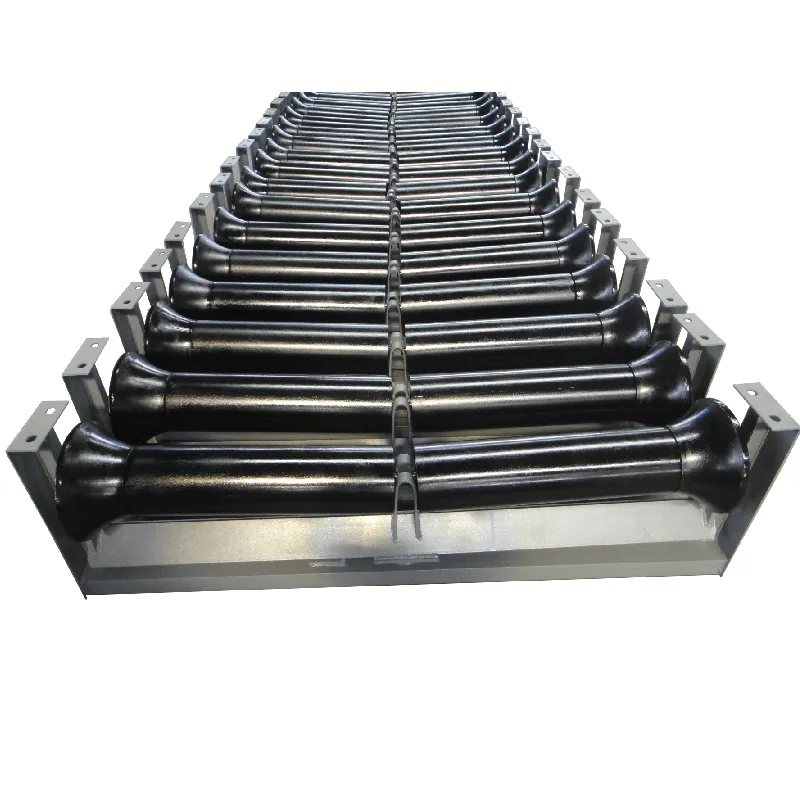

Suspension Idler

Garland idlers, integral components in modern conveyor systems, are not just tools for efficiency; they are essential for enhancing the durability and functionality of industrial operations. These sophisticated pieces of equipment are designed to handle bulk materials, providing unparalleled support and stability to conveyor belts that snake through factories, mining sites, and production lines across various industries.

A crucial aspect of garland idlers that underscores their authoritativeness in the industry is their compliance with international standards and certifications. Manufacturers adhere to stringent ISO guidelines, ensuring that these components meet rigorous quality and safety standards. This compliance is a testament to their reliability and is a critical factor when corporations seek to invest in or upgrade their conveyor systems. Trustworthiness in the context of garland idlers can be further highlighted through customer testimonials and field studies, which often emphasize the reduction in maintenance costs and improvements in system uptime following the installation of these idlers. Long-term users often report not only a decrease in conveyor-related incidents but also an increase in their systems' efficiency and longevity. The durability of garland idlers, combined with ease of maintenance, positions them as a trusted solution that minimizes operational hurdles. In conclusion, garland idlers stand out as a quintessential component in the arsenal of modern industrial equipment. By leveraging their design efficiency, expert selection based on operational needs, and adherence to international standards, industries can greatly enhance their production lines. Businesses that incorporate these idlers can expect increased durability of their conveyor systems, optimized performance, and ultimately, a greater return on investment. This positions garland idlers not only as functional elements but as strategic assets in the quest for industrial excellence.

A crucial aspect of garland idlers that underscores their authoritativeness in the industry is their compliance with international standards and certifications. Manufacturers adhere to stringent ISO guidelines, ensuring that these components meet rigorous quality and safety standards. This compliance is a testament to their reliability and is a critical factor when corporations seek to invest in or upgrade their conveyor systems. Trustworthiness in the context of garland idlers can be further highlighted through customer testimonials and field studies, which often emphasize the reduction in maintenance costs and improvements in system uptime following the installation of these idlers. Long-term users often report not only a decrease in conveyor-related incidents but also an increase in their systems' efficiency and longevity. The durability of garland idlers, combined with ease of maintenance, positions them as a trusted solution that minimizes operational hurdles. In conclusion, garland idlers stand out as a quintessential component in the arsenal of modern industrial equipment. By leveraging their design efficiency, expert selection based on operational needs, and adherence to international standards, industries can greatly enhance their production lines. Businesses that incorporate these idlers can expect increased durability of their conveyor systems, optimized performance, and ultimately, a greater return on investment. This positions garland idlers not only as functional elements but as strategic assets in the quest for industrial excellence.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS