Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 03, 2025 05:11

Back to list

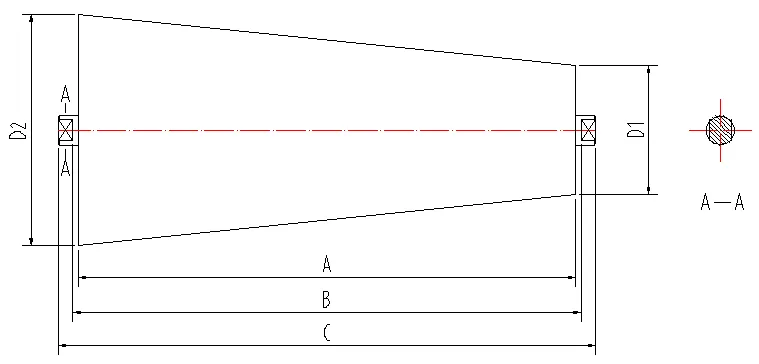

Impact Roller

Impact idler rollers are an often overlooked yet critical component in bulk material handling systems. These rollers, strategically positioned under loading zones or conveyor belt transfer points, play a key role in absorbing and dampening the impact of heavy materials as they are loaded onto conveyor systems. A genuine understanding of this product's significance requires delving into the experience of real-world applications, the expertise required for selecting quality idlers, and the authoritative knowledge that supports their continued development and application.

The authoritativeness of impact idler roller designs is undergirded by industry standards set by leading bodies such as the Conveyor Equipment Manufacturers Association (CEMA). Compliance with these standards ensures that the equipment delivers the high performance expected in rigorous situations. Research and development within this domain are ongoing, guided by pioneers in mechanical engineering and industry leaders who conduct comprehensive tests to push the limits of durability and efficiency. The adoption of cutting-edge technologies such as finite element analysis (FEA) allows for detailed simulations and optimizations, reinforcing the authoritative standing of current products as a culmination of decades of engineering advancement. Trustworthiness in selecting and maintaining impact idler rollers hinges on the credibility of manufacturers. Reputable suppliers provide full transparency in their testing data, provenance of materials, and customer testimonials. The support doesn't end at purchase; trusted manufacturers offer extensive after-sales services including installation guidance, maintenance training, and replacement part availability. This reliability builds a rapport with buyers, ensuring they can count on uninterrupted conveyor operations year after year. In conclusion, the realm of impact idler rollers is a vital yet nuanced sector within the broader scope of material handling solutions. Their effective application results not just from their ability to absorb impact but from the collective experience, expertise, authority, and trustworthiness embedded in their design and usage. By choosing quality impact idlers, businesses not only enhance operational efficiency but also safeguard their conveyor systems, ultimately maintaining a steady flow of production while minimizing costly interruptions.

The authoritativeness of impact idler roller designs is undergirded by industry standards set by leading bodies such as the Conveyor Equipment Manufacturers Association (CEMA). Compliance with these standards ensures that the equipment delivers the high performance expected in rigorous situations. Research and development within this domain are ongoing, guided by pioneers in mechanical engineering and industry leaders who conduct comprehensive tests to push the limits of durability and efficiency. The adoption of cutting-edge technologies such as finite element analysis (FEA) allows for detailed simulations and optimizations, reinforcing the authoritative standing of current products as a culmination of decades of engineering advancement. Trustworthiness in selecting and maintaining impact idler rollers hinges on the credibility of manufacturers. Reputable suppliers provide full transparency in their testing data, provenance of materials, and customer testimonials. The support doesn't end at purchase; trusted manufacturers offer extensive after-sales services including installation guidance, maintenance training, and replacement part availability. This reliability builds a rapport with buyers, ensuring they can count on uninterrupted conveyor operations year after year. In conclusion, the realm of impact idler rollers is a vital yet nuanced sector within the broader scope of material handling solutions. Their effective application results not just from their ability to absorb impact but from the collective experience, expertise, authority, and trustworthiness embedded in their design and usage. By choosing quality impact idlers, businesses not only enhance operational efficiency but also safeguard their conveyor systems, ultimately maintaining a steady flow of production while minimizing costly interruptions.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS