Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Mar . 05, 2025 01:26

Back to list

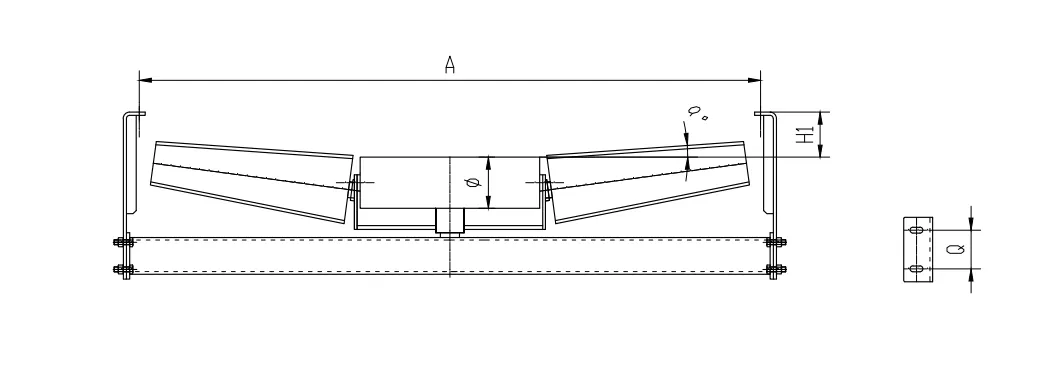

friction drive pulley

When exploring the realm of mechanical systems, the friction drive pulley emerges as a significant component revered for its efficiency and utility. Unlike traditional systems relying on belts or chains, the friction drive pulley distinguishes itself by leveraging the power of friction to transmit torque and motion between surfaces—usually through direct contact. For industries reliant on precision and adaptability, understanding the intricate dynamics of friction drive pulleys is not just beneficial but crucial.

From an expertise perspective, understanding the underlying physics of friction drive pulleys accentuates their appeal. The operation rests heavily on the coefficient of friction—determined by the materials in contact and the surface conditions. By selecting materials that maximize this coefficient, engineers can fine-tune the system to achieve desired torque transmissions without causing excessive wear or thermal buildup. This balancing act is critical and underscores the specialized knowledge necessary to optimize friction drive pulley systems. Throughout history, developments in material science have continually elevated their operational efficiency and reliability. Modern friction drive pulleys are often constructed from durable composites or engineered metals that withstand high stress and offer consistent friction levels over their operational lifespan. This evolution in materials not only enhances performance but also broadens the scope of applications, permitting these pulleys to be used in more varied and demanding environments. The credibility of friction drive pulleys is further validated by their widespread utilization across diverse fields, underscoring a robust trust in their capabilities. Companies that prioritize sustainability and efficiency have increasingly adopted these components to harness energy savings and extend equipment lifespans. As industries evolve and seek greener alternatives, the use of friction drive pulleys represents a forward-thinking approach aligned with modern technological and environmental standards. To summarize, friction drive pulleys blend efficiency, durability, and adaptability, making them indispensable in precision-oriented industries. Their distinctive mechanism, which reduces dependency on intermediary components, not only heightens efficiency but also minimizes maintenance challenges. An understanding grounded in expertise assures their optimal use, while ongoing advancements in material science continue to broaden their applicability and reliability. Therefore, in an ever-evolving industrial landscape, friction drive pulleys stand as a testament to innovation meeting practical utility, establishing themselves as both a trusted and authoritative component in mechanical design.

From an expertise perspective, understanding the underlying physics of friction drive pulleys accentuates their appeal. The operation rests heavily on the coefficient of friction—determined by the materials in contact and the surface conditions. By selecting materials that maximize this coefficient, engineers can fine-tune the system to achieve desired torque transmissions without causing excessive wear or thermal buildup. This balancing act is critical and underscores the specialized knowledge necessary to optimize friction drive pulley systems. Throughout history, developments in material science have continually elevated their operational efficiency and reliability. Modern friction drive pulleys are often constructed from durable composites or engineered metals that withstand high stress and offer consistent friction levels over their operational lifespan. This evolution in materials not only enhances performance but also broadens the scope of applications, permitting these pulleys to be used in more varied and demanding environments. The credibility of friction drive pulleys is further validated by their widespread utilization across diverse fields, underscoring a robust trust in their capabilities. Companies that prioritize sustainability and efficiency have increasingly adopted these components to harness energy savings and extend equipment lifespans. As industries evolve and seek greener alternatives, the use of friction drive pulleys represents a forward-thinking approach aligned with modern technological and environmental standards. To summarize, friction drive pulleys blend efficiency, durability, and adaptability, making them indispensable in precision-oriented industries. Their distinctive mechanism, which reduces dependency on intermediary components, not only heightens efficiency but also minimizes maintenance challenges. An understanding grounded in expertise assures their optimal use, while ongoing advancements in material science continue to broaden their applicability and reliability. Therefore, in an ever-evolving industrial landscape, friction drive pulleys stand as a testament to innovation meeting practical utility, establishing themselves as both a trusted and authoritative component in mechanical design.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS