Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Mar . 05, 2025 01:06

Back to list

driven pulley and driver pulley

In the realm of mechanics and industrial machinery, the interaction between driven and driver pulleys plays a pivotal role in the efficient functioning of numerous applications. When delving into the nuances of these mechanical components, understanding their distinct roles and interplay can greatly enhance operational efficiency and equipment longevity.

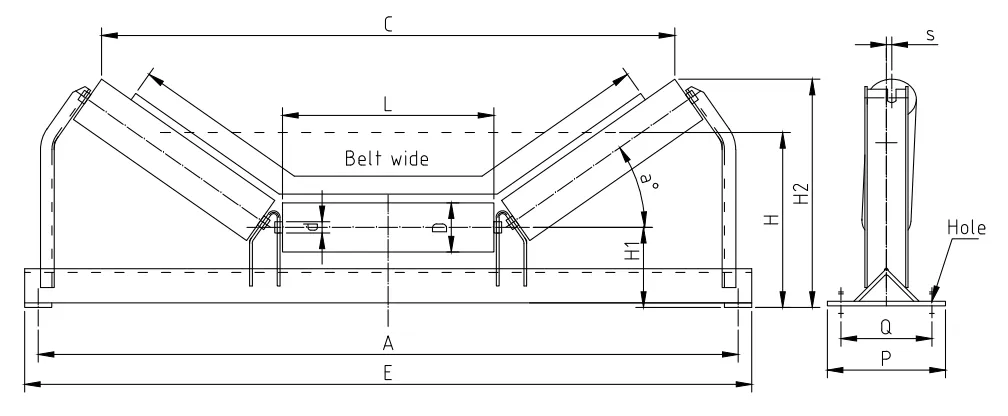

Additionally, understanding the speed ratio between the driver and driven pulley is vital. This ratio determines how fast the driven pulley turns compared to the driver, influencing the speed and torque of the entire system. A precise balance needs to be struck to maintain efficacy without overburdening any component within the mechanism. Applications Across Industries From automotive engines to intricate conveyor systems in industrial plants, the application scope for driven and driver pulleys is extensive. In the automotive industry, for instance, these components are integral in engine systems for driving ancillary components like alternators and air conditioning units. In manufacturing, they govern conveyor systems that streamline processing and packaging operations, enhancing productivity and efficiency. Tricks for Enhanced Performance To bolster the performance and reliability of belt and pulley systems, considering innovations like variable frequency drives (VFDs) can offer flexibility and control over motor speeds, thereby optimizing the performance of the driver pulse. Moreover, using high-quality belts and regularly updating components as per manufacturer recommendations are prudent measures to ensure sustained efficiency. Conclusion and Best Practices Proper understanding and maintenance of driven and driver pulleys can significantly impact the performance of mechanical systems. By emphasizing accurate installation and regular maintenance, companies can achieve higher efficiency levels. Investing in quality materials and innovation ensures increased durability and reduced unforeseen downtime. When optimizing such systems, seeking advice from professionals with a deep understanding of mechanical engineering can provide invaluable assistance. Their insights can guide proper component selection and maintenance practices, ultimately bolstering the trustworthiness of operations and the overall success of the system. Through this, businesses can ensure their mechanical frameworks operate with precision and reliability, aligning with modern technological and operational demands.

Additionally, understanding the speed ratio between the driver and driven pulley is vital. This ratio determines how fast the driven pulley turns compared to the driver, influencing the speed and torque of the entire system. A precise balance needs to be struck to maintain efficacy without overburdening any component within the mechanism. Applications Across Industries From automotive engines to intricate conveyor systems in industrial plants, the application scope for driven and driver pulleys is extensive. In the automotive industry, for instance, these components are integral in engine systems for driving ancillary components like alternators and air conditioning units. In manufacturing, they govern conveyor systems that streamline processing and packaging operations, enhancing productivity and efficiency. Tricks for Enhanced Performance To bolster the performance and reliability of belt and pulley systems, considering innovations like variable frequency drives (VFDs) can offer flexibility and control over motor speeds, thereby optimizing the performance of the driver pulse. Moreover, using high-quality belts and regularly updating components as per manufacturer recommendations are prudent measures to ensure sustained efficiency. Conclusion and Best Practices Proper understanding and maintenance of driven and driver pulleys can significantly impact the performance of mechanical systems. By emphasizing accurate installation and regular maintenance, companies can achieve higher efficiency levels. Investing in quality materials and innovation ensures increased durability and reduced unforeseen downtime. When optimizing such systems, seeking advice from professionals with a deep understanding of mechanical engineering can provide invaluable assistance. Their insights can guide proper component selection and maintenance practices, ultimately bolstering the trustworthiness of operations and the overall success of the system. Through this, businesses can ensure their mechanical frameworks operate with precision and reliability, aligning with modern technological and operational demands.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS