Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 16, 2025 01:41

Back to list

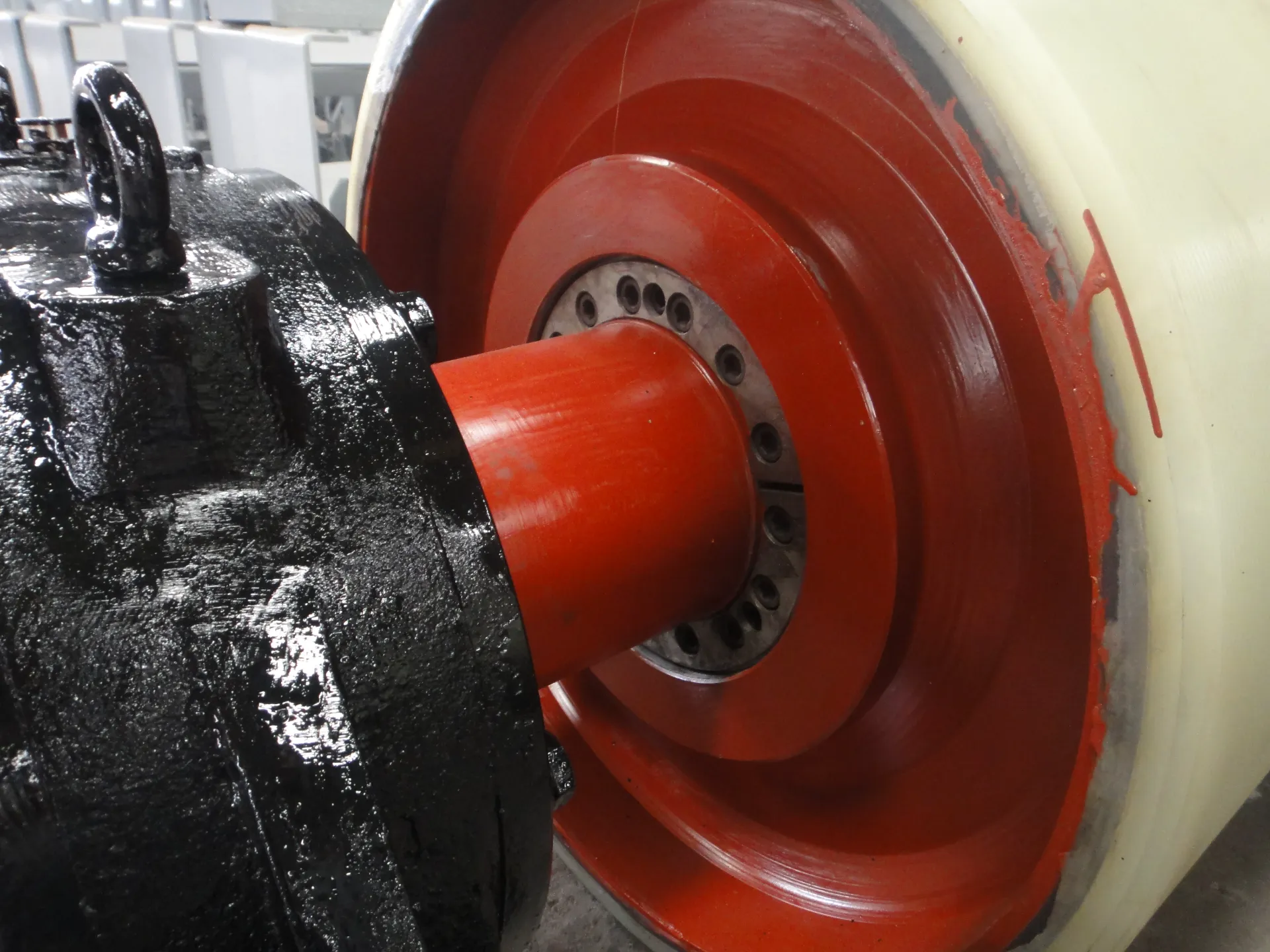

drive pulley

In the realm of industrial mechanics, the drive pulley plays an indispensable role, often serving as the unsung hero in numerous operations. Its function, reliability, and design significantly impact the overall performance of mechanical systems in which they operate. With the advancement of technology and the demand for increased efficiency, choosing the right drive pulley has become crucial for businesses aiming to optimize their machinery and bolster productivity.

Authoritativeness is integral to the selection process of drive pulleys as it relates to sourcing components from reputable suppliers. Industry leaders often engage with manufacturers who have a proven track record of innovation and quality assurance certifications. These manufacturers offer not only high-quality products but also valuable insights into optimizing pulley systems tailored to specific industrial needs. Established brands frequently provide comprehensive warranty packages, backing their products with assurances that reinforce their commitment to quality and long-term client support. Trustworthiness can be gauged by examining customer testimonials, industry certifications, and the longevity of the supplier's presence in the market. A trustworthy drive pulley supplier maintains transparency in their processes, offers robust customer support, and ensures compliance with international standards such as ISO and ANSI. Furthermore, engaging with suppliers who offer customized solutions allows businesses to craft pulley systems that meet exact operational requirements, ultimately leading to greater reliability and cost-effectiveness. In conclusion, while the drive pulley may seem a modest component in the vast machinery landscape, its impact on operational efficiency is substantial. Adopting a strategic approach—rooted in experience, expertise, authoritativeness, and trustworthiness—ensures that businesses not only enhance performance but also set a solid foundation for sustainable growth within their industrial operations. Investing in high-quality drive pulleys thus becomes not just a technical decision but a strategic business imperative.

Authoritativeness is integral to the selection process of drive pulleys as it relates to sourcing components from reputable suppliers. Industry leaders often engage with manufacturers who have a proven track record of innovation and quality assurance certifications. These manufacturers offer not only high-quality products but also valuable insights into optimizing pulley systems tailored to specific industrial needs. Established brands frequently provide comprehensive warranty packages, backing their products with assurances that reinforce their commitment to quality and long-term client support. Trustworthiness can be gauged by examining customer testimonials, industry certifications, and the longevity of the supplier's presence in the market. A trustworthy drive pulley supplier maintains transparency in their processes, offers robust customer support, and ensures compliance with international standards such as ISO and ANSI. Furthermore, engaging with suppliers who offer customized solutions allows businesses to craft pulley systems that meet exact operational requirements, ultimately leading to greater reliability and cost-effectiveness. In conclusion, while the drive pulley may seem a modest component in the vast machinery landscape, its impact on operational efficiency is substantial. Adopting a strategic approach—rooted in experience, expertise, authoritativeness, and trustworthiness—ensures that businesses not only enhance performance but also set a solid foundation for sustainable growth within their industrial operations. Investing in high-quality drive pulleys thus becomes not just a technical decision but a strategic business imperative.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS