Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

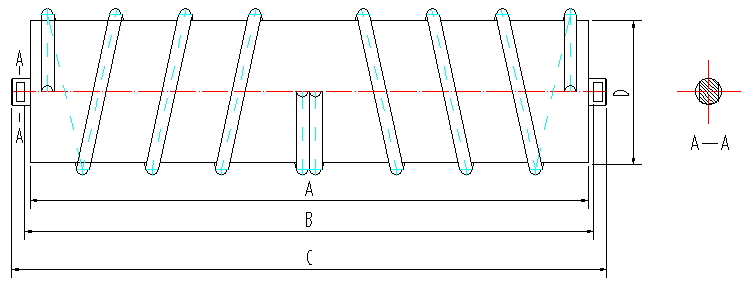

Zulu Automatic Cleaning Spiral Roller

Detail Description

Detail Description

The spiral cleaning device is bent with a thin round steel, enwound, and welded on the roller. which has an auxiliary cleaning effect on the belt when contacting with the stubborn residual material on the receiving surface of the conveyor belt.

Product Specification

Product Specification

|

Product Details |

Description |

Order Services |

|

Product Name: Self-Cleaning Spiral Rollers |

Rollers Material: Angle Steel、Channel Steel、Steel Pipe |

Minimum order:1 piece |

|

Origin Name: Hebei Province, China |

Shaft Material: Q235B、1045 High precision cold drawn steel |

Price: Negotiable |

|

Brand Name: AOHUA |

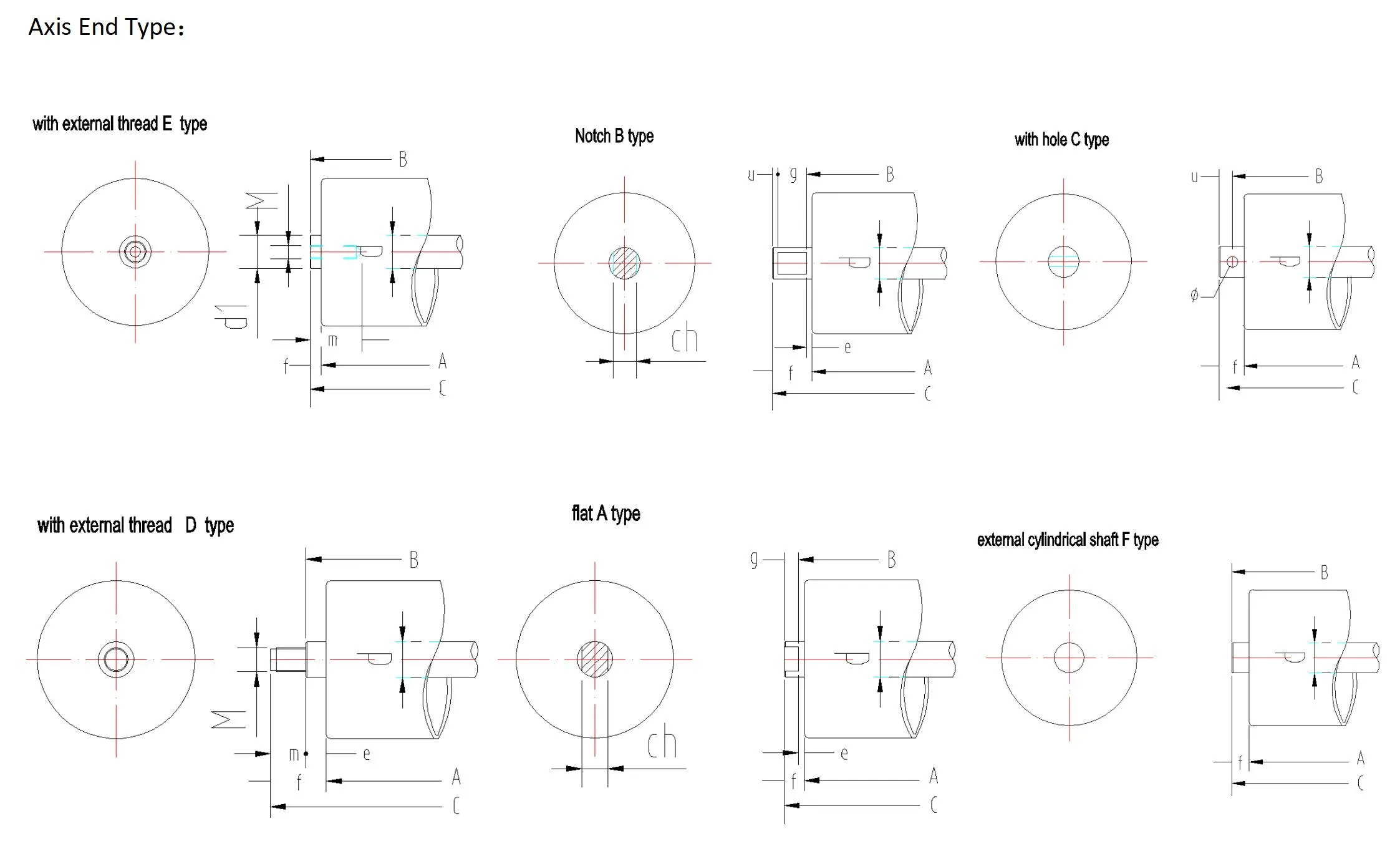

Shaft End Type:A、B、C、D、E、F or others |

Packing: Fumigation-free plywood box, iron frame, pallet |

|

Standard:CENA、ISO、DIN、JIS、DTII |

Welding: carbon dioxide gas shielded welding |

Delivery time:10-15days |

|

Belt Width:400-2400MM |

Welding Method: Automatic double end welding |

Payment Term: TT、LC |

|

Service life:30000 hours |

Seal Type:AH 、JIS 、TR 、DTII |

Shipping port: Tianjin Xingang、Shanghai、Qingdao |

|

Wall Thickness Range Of Roller: 2.5~6mm |

Bearing Brand:HRB、 ZWZ、 LYC、 SKF、 FAG 、NSK |

Before and After service: support online、Video technical support |

|

Diameter Range of Roller:48-219mm |

Color:Black、Red、 Green 、Blue、 or according to orders |

|

|

Diameter Range of Shaft:17-60mm |

Coating Process: Painting |

|

|

Length Range of Roller:150-3500mm |

Application: Coal mine, cement plant, crushing, power plant, steel mill, metallurgy, quarrying, printing, recycling industry and other conveying equipment |

|

|

Bearing Type:6203-6312 |

|

Product Parameters

Product Parameters

major model selection parameters for rollers: