Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 11, 2025 10:37

Back to list

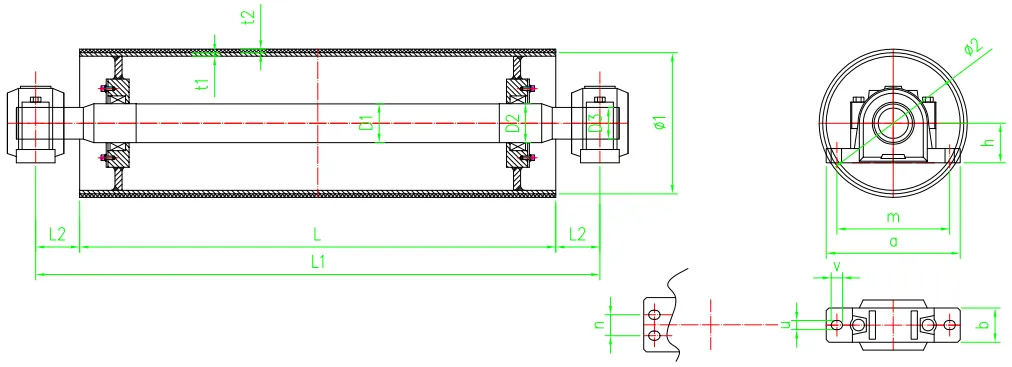

conveyor snub pulley

The conveyor snub pulley is an indispensable component in various industrial applications, serving a critical role in belt tension and alignment. This article explores the intricate details of snub pulleys, leveraging expertise and practical experiences to deliver authoritative insight into their functionality, selection, and maintenance.

From a trustworthiness perspective, the installation and maintenance of snub pulleys are critical to ensuring their efficient operation. A poorly aligned snub pulley not only reduces conveyor efficiency but can also lead to premature wear of the belt and other components. It is essential to engage qualified technicians during installation to verify alignment and tension settings. Moreover, regular inspections and maintenance checks are recommended to identify and rectify any misalignments or wear and tear early, thereby preventing costly downtimes. Experience shared by industry veterans underscores the importance of integrating snub pulleys into a preventative maintenance schedule. Practical insights suggest that routine lubrication and clearing of debris contribute significantly to the longevity and reliability of snub pulleys. For instance, some industries have seen a marked improvement in conveyor performance by implementing quarterly maintenance schedules, which include detailed inspections of the snub pulleys and adjacent components. Error-free operation of snub pulleys can be achieved by adhering to manufacturer guidelines and consulting with conveyor system experts. Collaborating with experienced engineers can provide an added advantage in optimizing the conveyor system for maximum efficiency and lifespan. Their input can be invaluable in addressing unique challenges, such as adapting standard conveyor systems to suit specialized industrial processes or upgrading existing installations to improve performance. In conclusion, the conveyor snub pulley is a pivotal element that contributes to the efficiency and reliability of conveyor systems. Through informed selection based on expertise and authoritative recommendations, alongside diligent maintenance practices, businesses can safeguard their operations against unexpected disruptions. By investing in quality components and expert guidance, industrial operations can achieve seamless functionality, bolstering productivity and ensuring the sustainability of their conveyor systems.

From a trustworthiness perspective, the installation and maintenance of snub pulleys are critical to ensuring their efficient operation. A poorly aligned snub pulley not only reduces conveyor efficiency but can also lead to premature wear of the belt and other components. It is essential to engage qualified technicians during installation to verify alignment and tension settings. Moreover, regular inspections and maintenance checks are recommended to identify and rectify any misalignments or wear and tear early, thereby preventing costly downtimes. Experience shared by industry veterans underscores the importance of integrating snub pulleys into a preventative maintenance schedule. Practical insights suggest that routine lubrication and clearing of debris contribute significantly to the longevity and reliability of snub pulleys. For instance, some industries have seen a marked improvement in conveyor performance by implementing quarterly maintenance schedules, which include detailed inspections of the snub pulleys and adjacent components. Error-free operation of snub pulleys can be achieved by adhering to manufacturer guidelines and consulting with conveyor system experts. Collaborating with experienced engineers can provide an added advantage in optimizing the conveyor system for maximum efficiency and lifespan. Their input can be invaluable in addressing unique challenges, such as adapting standard conveyor systems to suit specialized industrial processes or upgrading existing installations to improve performance. In conclusion, the conveyor snub pulley is a pivotal element that contributes to the efficiency and reliability of conveyor systems. Through informed selection based on expertise and authoritative recommendations, alongside diligent maintenance practices, businesses can safeguard their operations against unexpected disruptions. By investing in quality components and expert guidance, industrial operations can achieve seamless functionality, bolstering productivity and ensuring the sustainability of their conveyor systems.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS