Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 07, 2025 04:23

Back to list

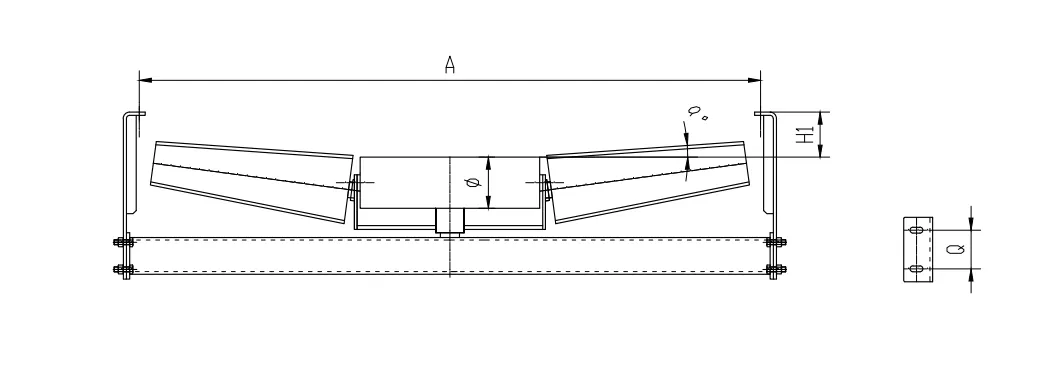

Slagging Pulley(Heavy Duty)

Conveyor pulley lagging plays a pivotal role in extending the lifespan and enhancing the efficiency of conveyor systems across various industries. Its significance cannot be understated, particularly in areas where heavy loads and continuous operation are prevalent. The purpose of this article is to provide an in-depth understanding of conveyor pulley lagging, focusing on authentic experiences and professional insights to help industry professionals make informed decisions.

Moreover, incorporating the latest innovations in lagging technology can further enhance operational outcomes. Self-cleaning lagging, for example, is gaining traction due to its ability to shed material build-up and prevent belt misalignment. Professionals who have adopted these advanced solutions report significant reductions in downtime and maintenance frequency, further validating the importance of choosing the right lagging material and technology. The narrative from seasoned conveyor technicians also underscores the relationship between lagging maintenance and system reliability. Regular inspections and timely replacement of worn lagging curtail potential operational hazards such as belt spillage and system overload. Trustworthy industry leaders advocate for the adoption of a proactive maintenance schedule as part of a broader risk management strategy. Real-world applications highlight the transformative effect of customized lagging solutions. Tailoring lagging to the specific needs of an operation—be it through selecting unique patterns or optimizing thickness—has repeatedly proven beneficial. For example, chemically resistant lagging options are exploited in environments exposed to corrosive materials, safeguarding the pulley and prolonging its service life. In conclusion, conveyor pulley lagging is more than just a protective measure; it’s a strategic investment in the longevity and efficiency of conveyor systems. Understanding the nuances of material selection, installation precision, and maintenance can turn challenges into opportunities for optimization. As industries continue to push the boundaries of productivity, establishing a partnership with reputable lagging suppliers and service providers becomes indispensable. Through leveraging expert knowledge and practical experience, businesses can secure a competitive edge, ensuring their conveyor systems operate seamlessly and sustainably.

Moreover, incorporating the latest innovations in lagging technology can further enhance operational outcomes. Self-cleaning lagging, for example, is gaining traction due to its ability to shed material build-up and prevent belt misalignment. Professionals who have adopted these advanced solutions report significant reductions in downtime and maintenance frequency, further validating the importance of choosing the right lagging material and technology. The narrative from seasoned conveyor technicians also underscores the relationship between lagging maintenance and system reliability. Regular inspections and timely replacement of worn lagging curtail potential operational hazards such as belt spillage and system overload. Trustworthy industry leaders advocate for the adoption of a proactive maintenance schedule as part of a broader risk management strategy. Real-world applications highlight the transformative effect of customized lagging solutions. Tailoring lagging to the specific needs of an operation—be it through selecting unique patterns or optimizing thickness—has repeatedly proven beneficial. For example, chemically resistant lagging options are exploited in environments exposed to corrosive materials, safeguarding the pulley and prolonging its service life. In conclusion, conveyor pulley lagging is more than just a protective measure; it’s a strategic investment in the longevity and efficiency of conveyor systems. Understanding the nuances of material selection, installation precision, and maintenance can turn challenges into opportunities for optimization. As industries continue to push the boundaries of productivity, establishing a partnership with reputable lagging suppliers and service providers becomes indispensable. Through leveraging expert knowledge and practical experience, businesses can secure a competitive edge, ensuring their conveyor systems operate seamlessly and sustainably.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS