Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 01, 2025 02:15

Back to list

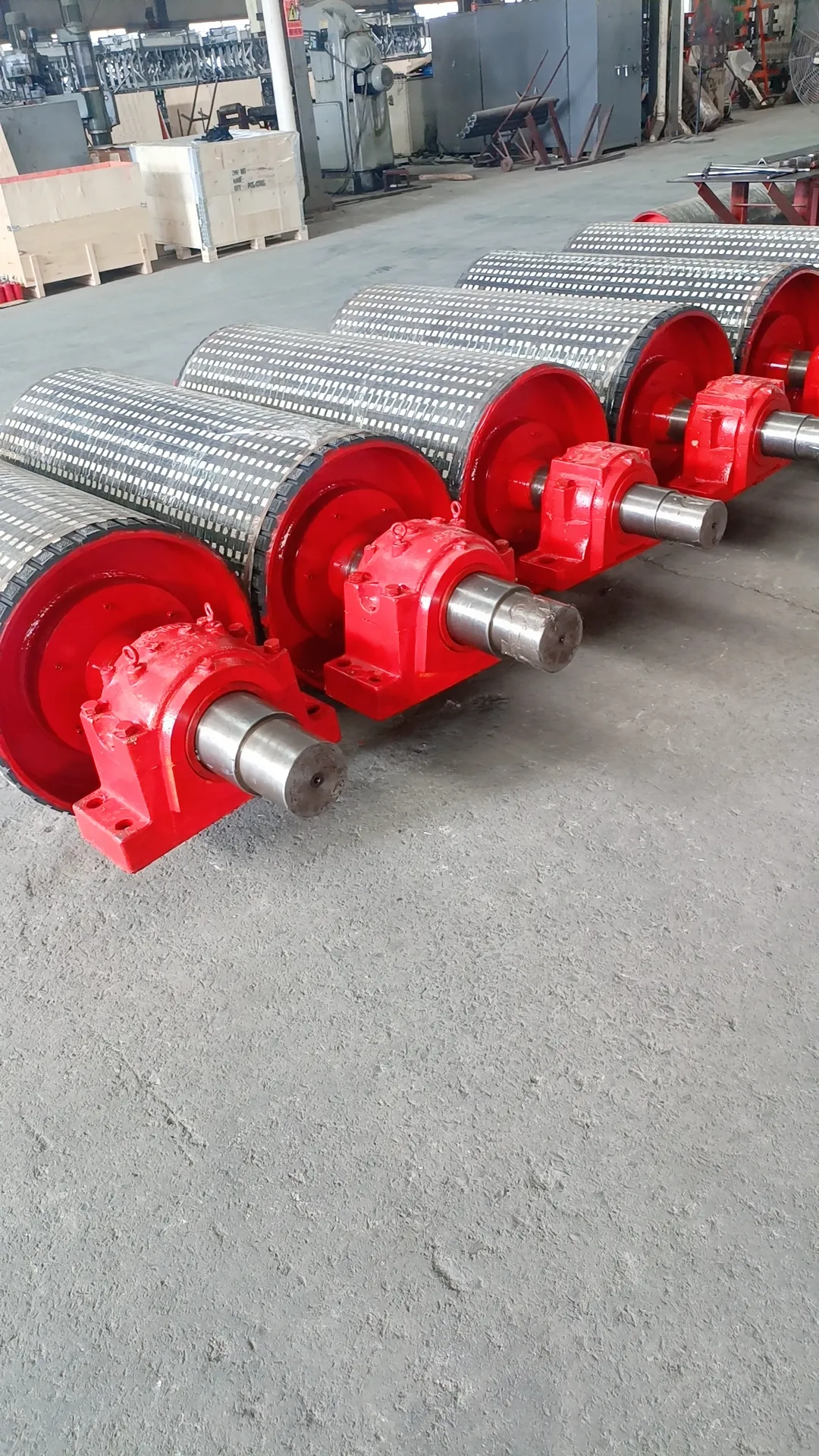

conveyor cleaning equipment

Conveyor cleaning equipment plays a crucial role in maintaining the efficiency and longevity of conveyor systems across various industries. As an individual with years of experience in the maintenance and optimization of these systems, I've witnessed firsthand the transformative impact that the right cleaning solutions can have. Whether you are in the food and beverage industry or managing a mining operation, the importance of keeping conveyors clean is paramount.

Commitment to expertise and authoritativeness in conveying solutions parallels a responsibility to environmental consciousness. The ideal cleaning equipment should not only comply with regulatory requirements but also exemplify environmentally sustainable practices. This involves choosing equipment that minimizes water and energy consumption, employing recyclable materials, and integrating waste management efficiencies. Trustworthiness in conveyor cleaning equipment is further emphasized through data integration and monitoring technologies. Incorporating IoT sensors and monitoring software provides operators with real-time data to optimize cleaning schedules, predict wear patterns, and prevent failures before they occur. This predictive maintenance approach ensures the long-term reliability and trustworthiness of your conveyor systems. Security considerations also play a pivotal role. While selecting equipment, verify that it can withstand the operational environment it will be placed in, whether it's exposure to chemicals, extreme temperatures, or abrasive materials. Equipment from reputable manufacturers often comes with certifications and has undergone rigorous testing, ensuring not just performance but also safety. As a seasoned professional in the field, investing in the right conveyor cleaning equipment is more than a business decision; it is a testament to an organization's dedication to efficiency, reliability, and sustainability. By addressing the cleaning needs of your conveyor systems comprehensively, you pave the way for operational excellence and enhanced profitability.

Commitment to expertise and authoritativeness in conveying solutions parallels a responsibility to environmental consciousness. The ideal cleaning equipment should not only comply with regulatory requirements but also exemplify environmentally sustainable practices. This involves choosing equipment that minimizes water and energy consumption, employing recyclable materials, and integrating waste management efficiencies. Trustworthiness in conveyor cleaning equipment is further emphasized through data integration and monitoring technologies. Incorporating IoT sensors and monitoring software provides operators with real-time data to optimize cleaning schedules, predict wear patterns, and prevent failures before they occur. This predictive maintenance approach ensures the long-term reliability and trustworthiness of your conveyor systems. Security considerations also play a pivotal role. While selecting equipment, verify that it can withstand the operational environment it will be placed in, whether it's exposure to chemicals, extreme temperatures, or abrasive materials. Equipment from reputable manufacturers often comes with certifications and has undergone rigorous testing, ensuring not just performance but also safety. As a seasoned professional in the field, investing in the right conveyor cleaning equipment is more than a business decision; it is a testament to an organization's dedication to efficiency, reliability, and sustainability. By addressing the cleaning needs of your conveyor systems comprehensively, you pave the way for operational excellence and enhanced profitability.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS