Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 13, 2025 17:31

Back to list

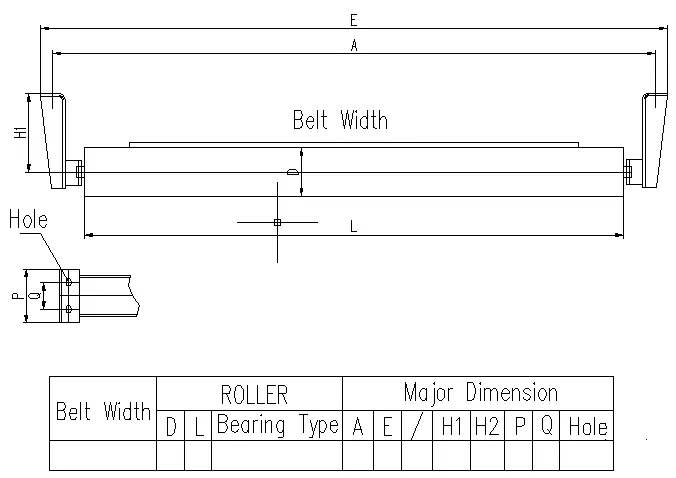

carrying roller

Carrying idler rollers are critical components in conveyor systems used across various industries, including mining, construction, and manufacturing. They support the conveyor belt, ensuring smooth and reliable operation, which minimizes downtime and enhances productivity. Understanding the role, benefits, and maintenance of carrying idler rollers can significantly impact the effectiveness of material handling processes.

Maintenance of carrying idler rollers is equally significant in ensuring their prolonged operation and effectiveness. Regular inspections should be a part of routine maintenance schedules. Operators need to identify signs of wear, misalignment, or other operational issues early to prevent complete system failure. Implementing predictive maintenance tactics, such as vibration analysis or thermal imaging, can help identify potential issues before they become significant problems, thus reducing repair costs and avoiding unexpected downtimes. Training personnel in the correct handling and maintenance of carrying idler rollers can improve their function and lifespan. Workers equipped with the knowledge to perform regular checks and simple repairs can reduce reliance on external specialists, thus cutting down operational costs over time. Proper training emphasizes the safety aspect as well, minimizing risks associated with handling heavy machinery. Moreover, adopting an eco-friendly approach by selecting energy-efficient idler rollers can have a positive impact on a company’s environmental footprint. These eco-conscious rollers are designed to reduce energy consumption, thereby aligning with global movements towards greener industrial practices and manifesting the company’s commitment to sustainability. In conclusion, carrying idler rollers may seem like minor components within the conveyor apparatus, yet their influence on system efficacy and durability is substantial. Companies looking to optimize their material handling processes should prioritize the quality, design, and maintenance of these rollers. By doing so, they not only enhance operational efficiency but also gain a competitive edge through reduced maintenance costs and increased productivity. Emphasizing reliability via well-constructed, durable rollers establishes a foundation of trustworthiness, proving to clients and stakeholders alike that the company is dedicated to excellence and sustainability in all aspects of its operations.

Maintenance of carrying idler rollers is equally significant in ensuring their prolonged operation and effectiveness. Regular inspections should be a part of routine maintenance schedules. Operators need to identify signs of wear, misalignment, or other operational issues early to prevent complete system failure. Implementing predictive maintenance tactics, such as vibration analysis or thermal imaging, can help identify potential issues before they become significant problems, thus reducing repair costs and avoiding unexpected downtimes. Training personnel in the correct handling and maintenance of carrying idler rollers can improve their function and lifespan. Workers equipped with the knowledge to perform regular checks and simple repairs can reduce reliance on external specialists, thus cutting down operational costs over time. Proper training emphasizes the safety aspect as well, minimizing risks associated with handling heavy machinery. Moreover, adopting an eco-friendly approach by selecting energy-efficient idler rollers can have a positive impact on a company’s environmental footprint. These eco-conscious rollers are designed to reduce energy consumption, thereby aligning with global movements towards greener industrial practices and manifesting the company’s commitment to sustainability. In conclusion, carrying idler rollers may seem like minor components within the conveyor apparatus, yet their influence on system efficacy and durability is substantial. Companies looking to optimize their material handling processes should prioritize the quality, design, and maintenance of these rollers. By doing so, they not only enhance operational efficiency but also gain a competitive edge through reduced maintenance costs and increased productivity. Emphasizing reliability via well-constructed, durable rollers establishes a foundation of trustworthiness, proving to clients and stakeholders alike that the company is dedicated to excellence and sustainability in all aspects of its operations.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS