Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 21, 2025 01:44

Back to list

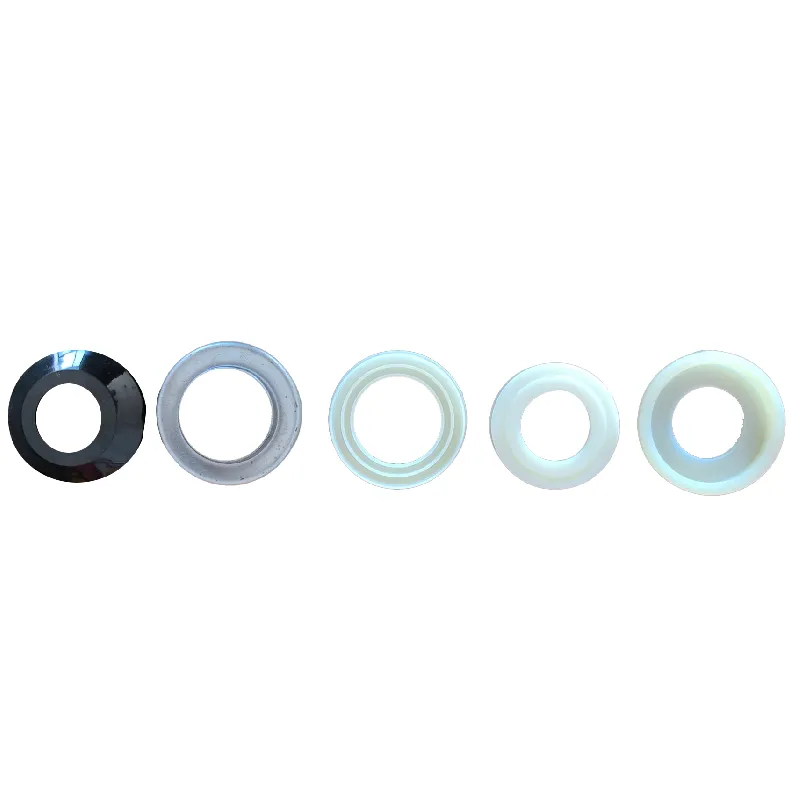

beater roller

In the intricate world of industrial machinery, beater rollers stand as unsung heroes, facilitating the seamless operation of various systems across multiple industries. These components may not grab headlines like other advanced technologies, but their significance in processes such as textile manufacturing, paper production, and material handling is undeniable.

Trustworthiness is further reinforced by the transparency that top manufacturers maintain with their clients. Detailed technical specifications, material certificates, and performance reports foster an environment of trust, enabling customers to make informed decisions. Moreover, many companies offer maintenance and support services as part of their package, ensuring that their clients receive comprehensive solutions tailored to their specific operational needs. Success stories from businesses that have adopted advanced beater rollers reveal the transformative impact these components can have. In one case, a leading paper mill implemented a new series of precision beater rollers from TechRoll Solutions. The result? A significant boost in throughput and product quality, along with a reduction in maintenance hours by 40%. Such examples highlight the crucial role that the right beater roller plays in enhancing operational efficiency and product quality. As innovation continues to drive the evolution of industrial machinery, the future of beater rollers looks promising. Cutting-edge technologies such as 3D printing and IoT integration are poised to redefine manufacturing precision and operational efficiency. As these advancements unfold, both seasoned operators and new entrants in the industry must remain aware of emerging trends and technologies to remain competitive. In conclusion, beater rollers are far from being mere components; they are pivotal to the success of multiple industrial processes. Whether you are an industry veteran or a newcomer exploring machinery options, investing in high-quality, performance-oriented beater rollers is a step toward ensuring operational success and product excellence. The marriage of experience, expertise, authority, and trust cements their role as indispensable elements in the realms of textile, paper, and beyond.

Trustworthiness is further reinforced by the transparency that top manufacturers maintain with their clients. Detailed technical specifications, material certificates, and performance reports foster an environment of trust, enabling customers to make informed decisions. Moreover, many companies offer maintenance and support services as part of their package, ensuring that their clients receive comprehensive solutions tailored to their specific operational needs. Success stories from businesses that have adopted advanced beater rollers reveal the transformative impact these components can have. In one case, a leading paper mill implemented a new series of precision beater rollers from TechRoll Solutions. The result? A significant boost in throughput and product quality, along with a reduction in maintenance hours by 40%. Such examples highlight the crucial role that the right beater roller plays in enhancing operational efficiency and product quality. As innovation continues to drive the evolution of industrial machinery, the future of beater rollers looks promising. Cutting-edge technologies such as 3D printing and IoT integration are poised to redefine manufacturing precision and operational efficiency. As these advancements unfold, both seasoned operators and new entrants in the industry must remain aware of emerging trends and technologies to remain competitive. In conclusion, beater rollers are far from being mere components; they are pivotal to the success of multiple industrial processes. Whether you are an industry veteran or a newcomer exploring machinery options, investing in high-quality, performance-oriented beater rollers is a step toward ensuring operational success and product excellence. The marriage of experience, expertise, authority, and trust cements their role as indispensable elements in the realms of textile, paper, and beyond.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS