Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu wing pulley manufacturer

The Rise of Wing Pulley Manufacturers A Boon for Industries

In the world of manufacturing and logistics, the demand for specialized components has continuously evolved. One such component, pivotal in enhancing the efficiency of various mechanical systems, is the wing pulley. Manufacturers of wing pulleys have seen a remarkable rise in interest due to advancements in technology and increasing industrial requirements.

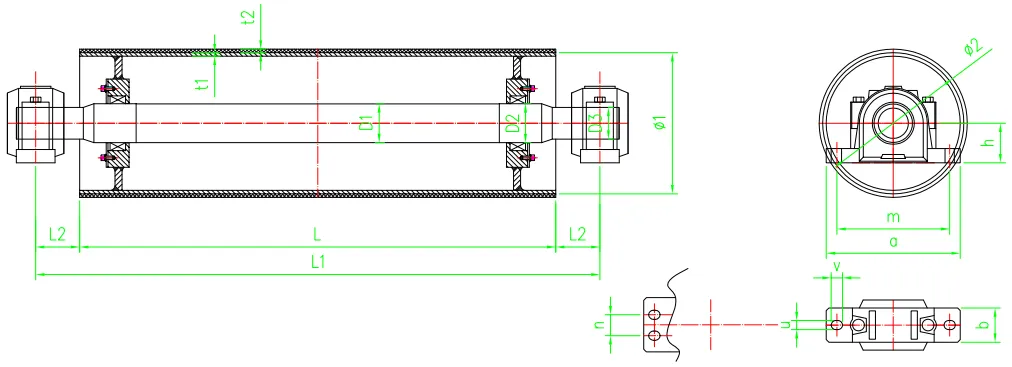

Wing pulleys are designed with a unique geometry, featuring a series of wings or scoops that extend radially from the pulley’s center. This innovative design allows for improved material handling, especially in conveyor systems. The wings aid in reducing material buildup around the pulley, which is crucial in applications where bulk materials like gravel, sand, and ores are transported. This not only minimizes maintenance requirements but also extends the lifespan of both the pulley and the belt.

The need for wing pulleys is particularly evident in industries such as mining, agriculture, and recycling, where heavy loads and abrasive materials are common. In mining operations, for example, the efficiency with which materials are moved can significantly impact productivity and operational costs. Wing pulleys contribute to smoother operation by preventing spillage and minimizing wear and tear on the conveyor belt. Consequently, companies are investing in high-quality wing pulleys from reputable manufacturers to ensure optimal performance in their systems.

wing pulley manufacturer

As environmental regulations tighten, manufacturers are also adapting their wing pulley designs to meet sustainability criteria. Modern wing pulleys are often fabricated from lightweight, durable materials that not only enhance performance but also reduce energy consumption. This shift is reflective of a broader trend in manufacturing, where energy efficiency and environmental responsibility are becoming paramount. Wing pulley manufacturers that focus on sustainable practices are likely to gain a competitive edge in the market.

Moreover, the technological advancements in manufacturing processes have enabled wing pulley manufacturers to offer customized solutions. Today’s industrial customers often require components that meet specific operational demands. As a result, leading manufacturers are investing in advanced engineering and manufacturing techniques, such as 3D printing and computer-aided design, to produce tailor-made wing pulleys that cater to unique requirements. This ability to customize not only meets the immediate needs of clients but also fosters long-term partnerships as manufacturers prove their value in providing bespoke solutions.

In the digital age, wing pulley manufacturers are leveraging online platforms to reach a broader audience. E-commerce and digital marketing strategies enable them to showcase their products, highlighting features and benefits that resonate with potential customers. By providing detailed technical specifications and maintenance information, manufacturers can assist clients in making informed decisions, contributing to customer satisfaction and loyalty.

In conclusion, the growing prominence of wing pulley manufacturers is indicative of the broader trends within industrial manufacturing. With innovations in design, increased demand for customized solutions, and a commitment to sustainability, these manufacturers are well-positioned to meet the evolving needs of various industries. As businesses continue to seek efficiency and reliability in their operations, the role of wing pulleys will undoubtedly remain crucial, promising strong prospects for manufacturers in the years to come.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025