Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 28, 2025 04:38

Back to list

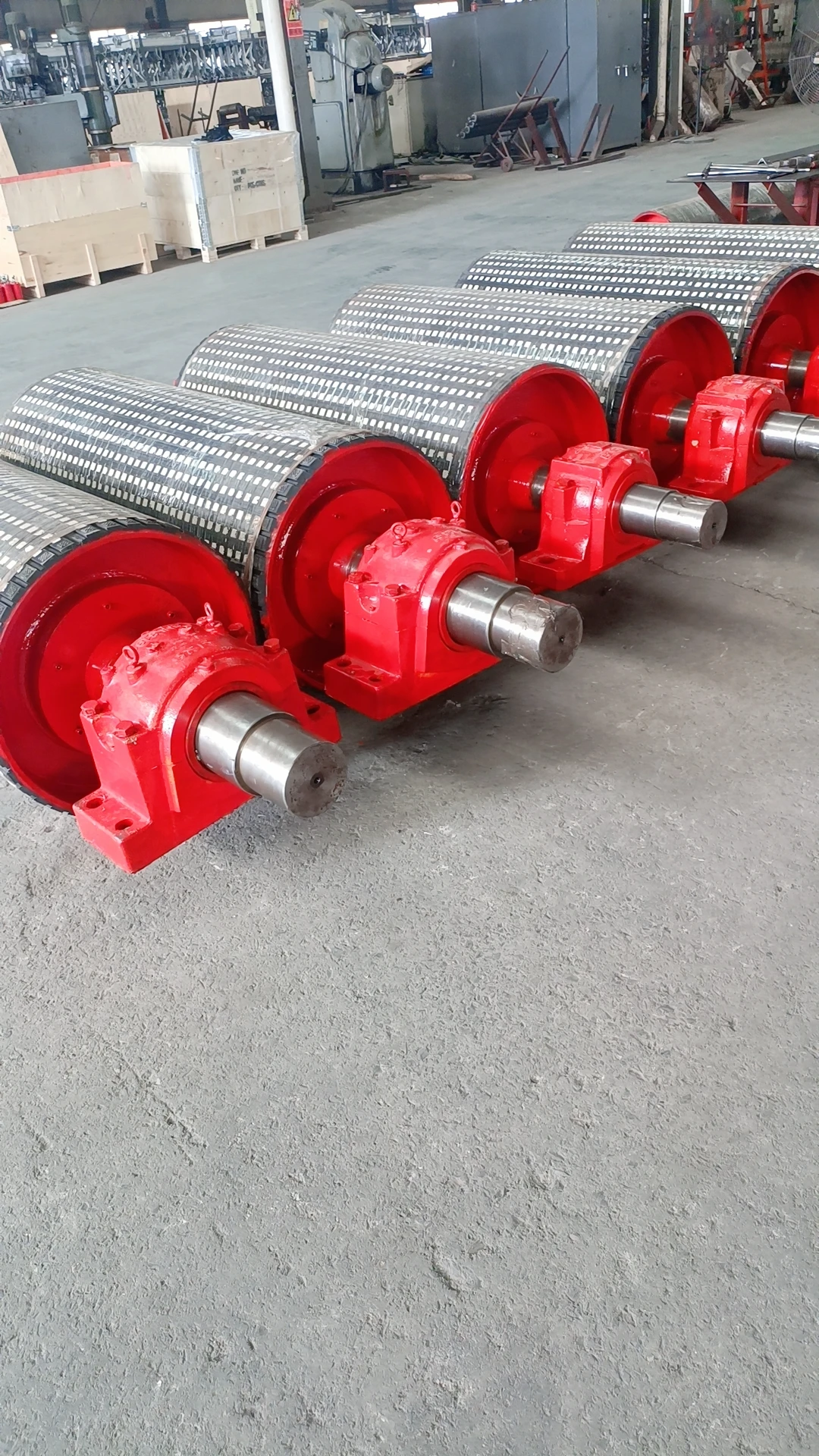

Wing Pulley

In the complex realm of conveyor systems within industrial settings, the wing pulley conveyor stands out as a critical component. Renowned for its durability and efficiency, understanding its application and advantages can significantly influence the performance of your conveyor system.

The authoritativeness of wing pulley conveyors is backed by numerous case studies and industry endorsements. Leading manufacturers and engineering experts advocate for their use in industries such as mining, agriculture, and recycling, where conveyors must perform steadfastly despite challenging conditions. With a higher resistance to bulk material spillages and its ability to shed sticky substances, the wing pulley conveyor enhances overall productivity and reduces environmental cleanup costs. Trustworthiness is built through consistent performance, and wing pulley conveyors rarely disappoint. Industry-standard testing and real-world application have solidified their reputation as robust and reliable. Employing materials like high-strength steel and precision-engineered components, these conveyors stand up to a variety of harsh environments. Furthermore, companies have observed an increase in trust from stakeholders due to the reduction of operational interruptions and improved safety metrics. In conclusion, the wing pulley conveyor is an indispensable asset for industries that demand efficiency, durability, and low maintenance. The wing design not only ensures the optimal performance of the conveyor systems but also stands as a testament to engineering ingenuity in addressing the daily challenges faced by businesses. Enhancing your operation with a wing pulley conveyor positions your business not just as an efficient entity, but as a leader in employing innovative solutions to industrial transportation issues. With a growing emphasis on reliability and reduced operational costs, making the switch to wing pulley conveyors is an investment in future-proofing your industrial processes.

The authoritativeness of wing pulley conveyors is backed by numerous case studies and industry endorsements. Leading manufacturers and engineering experts advocate for their use in industries such as mining, agriculture, and recycling, where conveyors must perform steadfastly despite challenging conditions. With a higher resistance to bulk material spillages and its ability to shed sticky substances, the wing pulley conveyor enhances overall productivity and reduces environmental cleanup costs. Trustworthiness is built through consistent performance, and wing pulley conveyors rarely disappoint. Industry-standard testing and real-world application have solidified their reputation as robust and reliable. Employing materials like high-strength steel and precision-engineered components, these conveyors stand up to a variety of harsh environments. Furthermore, companies have observed an increase in trust from stakeholders due to the reduction of operational interruptions and improved safety metrics. In conclusion, the wing pulley conveyor is an indispensable asset for industries that demand efficiency, durability, and low maintenance. The wing design not only ensures the optimal performance of the conveyor systems but also stands as a testament to engineering ingenuity in addressing the daily challenges faced by businesses. Enhancing your operation with a wing pulley conveyor positions your business not just as an efficient entity, but as a leader in employing innovative solutions to industrial transportation issues. With a growing emphasis on reliability and reduced operational costs, making the switch to wing pulley conveyors is an investment in future-proofing your industrial processes.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS