Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Innovations in Wing Pulley Conveyor Systems for Enhanced Material Handling Efficiency

Understanding Wing Pulley Conveyors A Comprehensive Overview

Wing pulley conveyors play a crucial role in various industrial applications, particularly in the transportation of bulk materials. These systems are designed to provide optimal material handling solutions, ensuring efficient and reliable operation. In this article, we will explore the design, functionality, and advantages of wing pulley conveyors, as well as their significance in modern industrial processes.

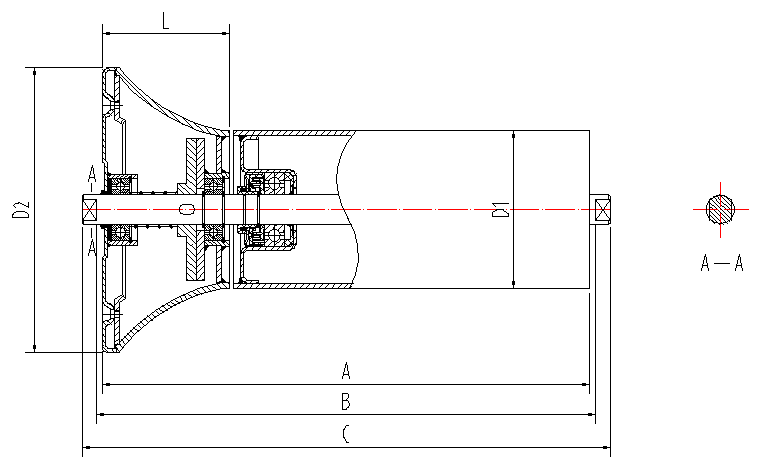

A wing pulley is characterized by its unique design, featuring two wings or flanges positioned at an angle to the conveyor belt. This structure creates a larger surface area for material contact while reducing the likelihood of material buildup. The wings allow for effective cleaning of the belt, minimizing carryback and improving overall system efficiency. Wing pulleys are typically used at the tail end of a conveyor system to facilitate the return of the belt and to assist in the discharge of material.

One of the standout features of wing pulley conveyors is their ability to handle various types of materials, including heavy aggregates, grains, and bulk powders. The design of the wings helps in controlling belt tracking, which is crucial for preventing belt misalignment and minimizing wear and tear. This is especially important in scenarios where the conveyor systems operate under dynamic loads and varying speeds.

wing pulley conveyor

The durability of wing pulleys is another key advantage. Made from high-quality materials, they are built to withstand harsh operating conditions and resist damage from abrasive materials. This longevity reduces the need for frequent replacements and maintenance, translating to cost savings for businesses. Furthermore, the open design of wing pulleys allows for easy inspection and maintenance, ensuring that potential issues can be identified and rectified promptly.

In terms of applications, wing pulley conveyors are utilized in numerous industries, including mining, agriculture, and construction. They are integral to processes such as material loading and unloading, stockpiling, and transportation across various distances. Given the increasing demand for efficient material handling solutions, the popularity of wing pulleys has surged, leading to innovations in design and technology.

Moreover, the environmental benefits of using wing pulley conveyors cannot be overlooked. By reducing carryback and enhancing cleaning capabilities, these systems contribute to diminished material wastage. This efficiency not only improves productivity but also supports sustainability efforts within industrial operations.

In summary, wing pulley conveyors are essential components in modern material handling systems. Their innovative design, durability, and operational efficiency make them ideal for a wide range of industrial applications. As industries continue to evolve and seek out more efficient methods of material transport, the significance of wing pulley systems will likely continue to grow, making them an indispensable asset in the realm of engineering and industrial operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025