Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 12:00

Back to list

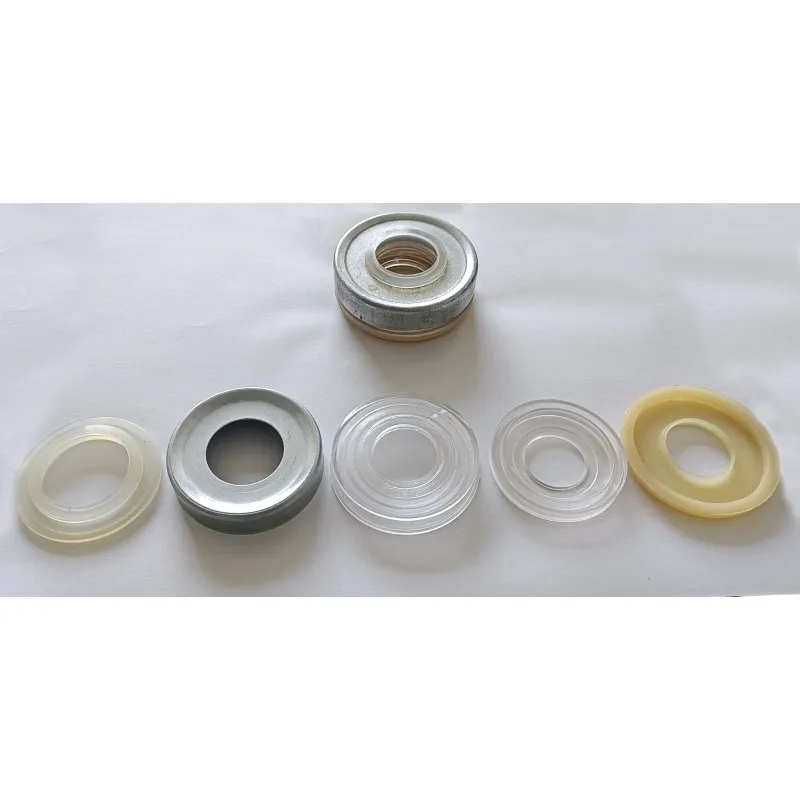

Wing Pulley

In the intricate world of industrial machinery and conveyor systems, the non-drive pulley plays a pivotal role that often goes unnoticed. Serving as a quintessential component in various applications, its presence is integral to ensuring efficient and smooth operation within these systems. But what exactly makes the non-drive pulley so critical, and why should businesses pay more attention to its qualities and uses?

Authoritativeness is further bolstered by manufacturers who adhere strictly to industry standards and certifications. Brands with ISO-certified production processes guarantee a level of quality and trustworthiness that sets them apart. Reviews and case studies from other companies utilizing non-drive pulleys in their operations often highlight issues such as noise reduction, minimal maintenance needs, and energy efficiency, all crucial factors influenced by the pulley's design and material. From a trustworthiness perspective, businesses seek suppliers who offer transparent warranties and post-purchase support. The non-drive pulley, while a seemingly minor component, can influence the overall integrity of an industrial operation. As such, manufacturers who provide detailed installation guides, troubleshooting assistance, and prompt customer service gain a reputation as dependable partners in business success. Ultimately, the non-drive pulley's role in systems might be passive, but its impact is proactive. Companies aiming to optimize their machinery's functionality should regard these pulleys not as mere spare parts, but as strategic elements worthy of careful selection and maintenance. By investing in high-quality non-drive pulleys, businesses can ensure that their machinery runs smoothly, efficiently, and reliably, reinforcing their operational goals and contributing to overall productivity.

Authoritativeness is further bolstered by manufacturers who adhere strictly to industry standards and certifications. Brands with ISO-certified production processes guarantee a level of quality and trustworthiness that sets them apart. Reviews and case studies from other companies utilizing non-drive pulleys in their operations often highlight issues such as noise reduction, minimal maintenance needs, and energy efficiency, all crucial factors influenced by the pulley's design and material. From a trustworthiness perspective, businesses seek suppliers who offer transparent warranties and post-purchase support. The non-drive pulley, while a seemingly minor component, can influence the overall integrity of an industrial operation. As such, manufacturers who provide detailed installation guides, troubleshooting assistance, and prompt customer service gain a reputation as dependable partners in business success. Ultimately, the non-drive pulley's role in systems might be passive, but its impact is proactive. Companies aiming to optimize their machinery's functionality should regard these pulleys not as mere spare parts, but as strategic elements worthy of careful selection and maintenance. By investing in high-quality non-drive pulleys, businesses can ensure that their machinery runs smoothly, efficiently, and reliably, reinforcing their operational goals and contributing to overall productivity.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS