Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 20, 2025 02:37

Back to list

winged tail pulley

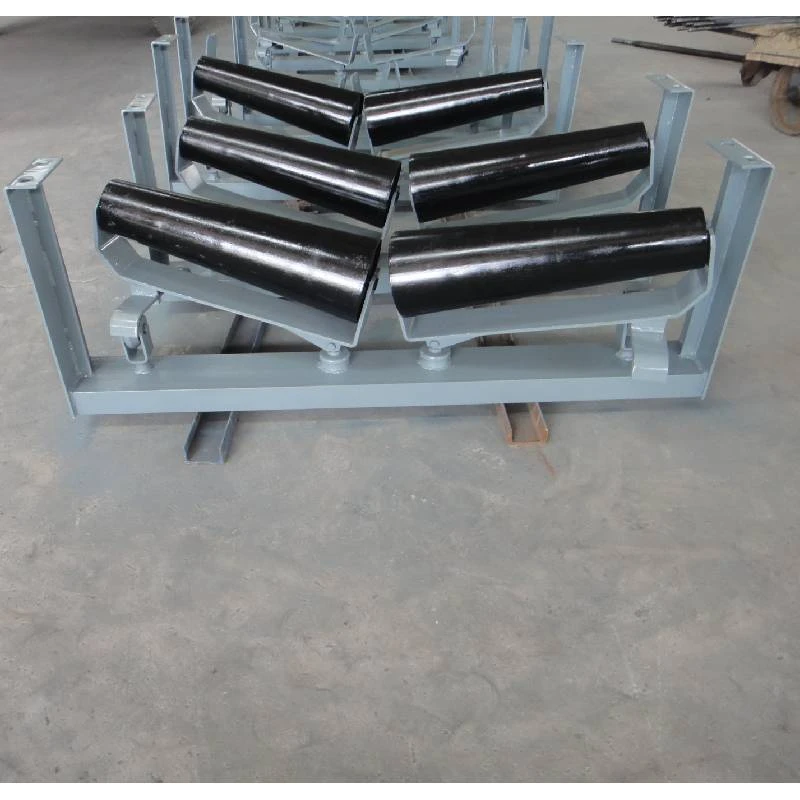

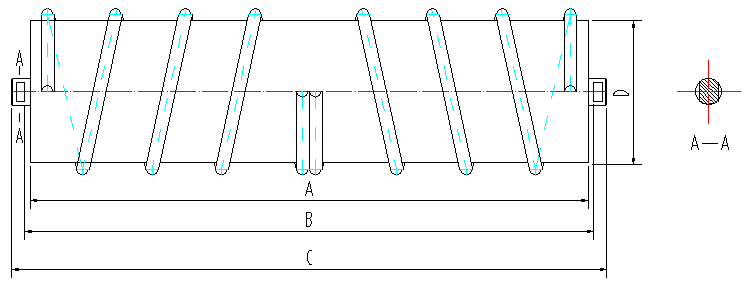

Winged tail pulleys are integral components in diverse industries, offering significant advantages for conveyor systems and enhancing operational efficiency. These specialized pulleys are engineered to reduce the risk of material buildup, a crucial factor in maintaining seamless operations in sectors such as mining, manufacturing, and material handling.

Trust in winged tail pulleys is reinforced by their proven track record and widespread adoption across industries. Testimonials from seasoned industry practitioners consistently emphasize the reliability and efficiency gains attributable to these components. These positive endorsements are bolstered by empirical data demonstrating significant reductions in belt slip and increased material throughput. As the industry evolves, innovations in material science and engineering continue to expand the capabilities of winged tail pulleys. Emerging trends emphasize eco-friendly materials and designs that align with sustainable industrial practices. This shift towards sustainability not only addresses environmental concerns but also aligns with regulatory standards increasingly demanded across global markets. The versatility of winged tail pulleys further enhances their appeal across a wide range of applications. From aggregate processing plants to recycling facilities, the ability of these pulleys to adapt to different material types and system configurations solidifies their status as an indispensable component in modern conveyor systems. As a result, companies deploying winged tail pulleys can expect a comprehensive enhancement in their operational efficiencies and a commensurate rise in their competitive edge within their respective markets. In conclusion, winged tail pulleys are not merely ancillary components but essential instruments of efficiency in conveyor belt systems. Through their innovative design, expert manufacturing, and proven performance, they deliver substantial returns on investment by ensuring smooth, reliable, and cost-effective industrial operations. As industries continue to seek ways to augment their productivity and sustainability, the adoption of advanced pulley systems like the winged tail pulley is poised to play a pivotal role in shaping the future of material handling and processing fields.

Trust in winged tail pulleys is reinforced by their proven track record and widespread adoption across industries. Testimonials from seasoned industry practitioners consistently emphasize the reliability and efficiency gains attributable to these components. These positive endorsements are bolstered by empirical data demonstrating significant reductions in belt slip and increased material throughput. As the industry evolves, innovations in material science and engineering continue to expand the capabilities of winged tail pulleys. Emerging trends emphasize eco-friendly materials and designs that align with sustainable industrial practices. This shift towards sustainability not only addresses environmental concerns but also aligns with regulatory standards increasingly demanded across global markets. The versatility of winged tail pulleys further enhances their appeal across a wide range of applications. From aggregate processing plants to recycling facilities, the ability of these pulleys to adapt to different material types and system configurations solidifies their status as an indispensable component in modern conveyor systems. As a result, companies deploying winged tail pulleys can expect a comprehensive enhancement in their operational efficiencies and a commensurate rise in their competitive edge within their respective markets. In conclusion, winged tail pulleys are not merely ancillary components but essential instruments of efficiency in conveyor belt systems. Through their innovative design, expert manufacturing, and proven performance, they deliver substantial returns on investment by ensuring smooth, reliable, and cost-effective industrial operations. As industries continue to seek ways to augment their productivity and sustainability, the adoption of advanced pulley systems like the winged tail pulley is poised to play a pivotal role in shaping the future of material handling and processing fields.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS