Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 23, 2025 05:12

Back to list

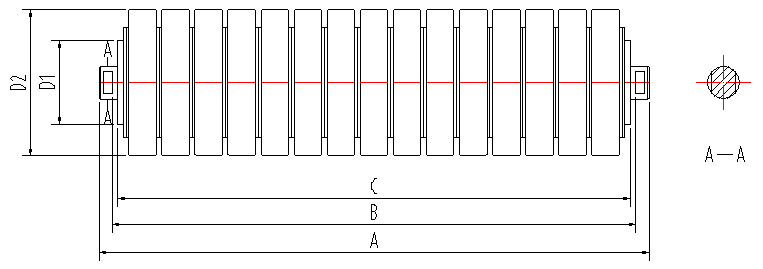

Guide Roller

Vertical roller technology has surged to the forefront of industrial advancements, becoming a pivotal component in industries such as cement and mining. Designed to serve heavy-duty operations, these machines are the epitome of modern engineering, marrying efficiency with reliability. Their ability to revolutionize material processing makes them indispensable.

Furthermore, vertical rollers have a versatile application range. They are adept at handling materials with varying moisture contents and hardness levels. This adaptability makes them suitable for a wide array of products beyond cement, including slag, coal, and industrial minerals. The ability to switch between products without extensive machine alterations speaks to their engineering excellence. To highlight the professional aspect, substantial research and development continue to enhance these machines' capabilities. Leading manufacturers invest heavily in R&D, aiming to improve the rollers' energy efficiency and grinding capabilities further. Current advancements show promising developments in AI integration, where smart rollers can auto-adjust their operations based on feed material properties, maximizing efficiency even more. For businesses intent on retaining a competitive edge, understanding the strategic advantage of deploying vertical roller technology is fundamental. Integrating these machines into operations is a sound investment that ensures long-term sustainability and quality improvement. Their contribution is increasingly recognized as pivotal, not merely auxiliary, in the production chain. In conclusion, the relevance of vertical rollers in modern industry cannot be overstated. They offer critical advantages in energy efficiency, precision, reliability, and adaptability. For those in manufacturing, particularly in sectors like cement and mining, embracing this technology is not just beneficial—it is essential. These machines are not just tools of the trade; they are the linchpin of production efficiency and product consistency. Pioneers in industries utilizing vertical roller technology are setting trends, ensuring they remain at the cutting edge of innovation and industry standards.

Furthermore, vertical rollers have a versatile application range. They are adept at handling materials with varying moisture contents and hardness levels. This adaptability makes them suitable for a wide array of products beyond cement, including slag, coal, and industrial minerals. The ability to switch between products without extensive machine alterations speaks to their engineering excellence. To highlight the professional aspect, substantial research and development continue to enhance these machines' capabilities. Leading manufacturers invest heavily in R&D, aiming to improve the rollers' energy efficiency and grinding capabilities further. Current advancements show promising developments in AI integration, where smart rollers can auto-adjust their operations based on feed material properties, maximizing efficiency even more. For businesses intent on retaining a competitive edge, understanding the strategic advantage of deploying vertical roller technology is fundamental. Integrating these machines into operations is a sound investment that ensures long-term sustainability and quality improvement. Their contribution is increasingly recognized as pivotal, not merely auxiliary, in the production chain. In conclusion, the relevance of vertical rollers in modern industry cannot be overstated. They offer critical advantages in energy efficiency, precision, reliability, and adaptability. For those in manufacturing, particularly in sectors like cement and mining, embracing this technology is not just beneficial—it is essential. These machines are not just tools of the trade; they are the linchpin of production efficiency and product consistency. Pioneers in industries utilizing vertical roller technology are setting trends, ensuring they remain at the cutting edge of innovation and industry standards.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS