Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Functionality and Benefits of Vertical Guide Rollers

Understanding Vertical Guide Rollers A Comprehensive Overview

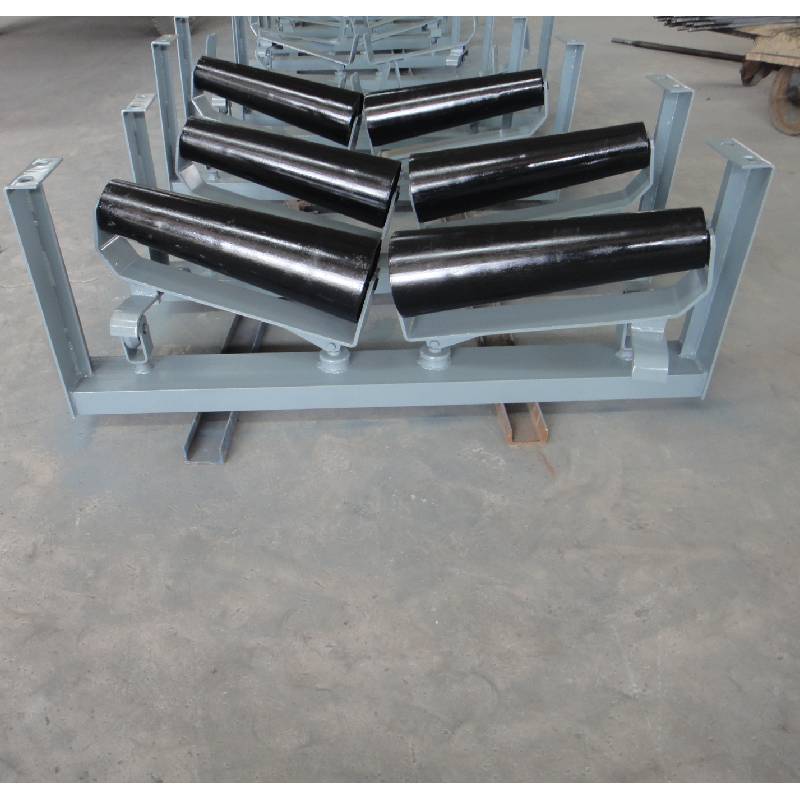

Vertical guide rollers are integral components used in various industries, particularly in material handling, manufacturing, and construction. Their primary role is to guide and support moving components, ensuring smooth and efficient operation in automated systems. The design and functionality of vertical guide rollers are critical for enhancing performance, increasing longevity, and reducing downtime in industrial applications.

What Are Vertical Guide Rollers?

Vertical guide rollers are cylindrical components mounted vertically to provide guidance for objects that move vertically. They typically consist of a bearing-supported roller that rotates smoothly around a fixed axis, allowing materials to slide, roll, or move with minimal friction. The main purpose of these rollers is to maintain proper alignment and prevent misalignment during operation, which can lead to operational inefficiencies or equipment damage.

Applications of Vertical Guide Rollers

Vertical guide rollers find applications across multiple sectors, including

1. Material Handling In warehouses and distribution centers, vertical guide rollers facilitate the movement of conveyor belts and palletizing systems. They help in aligning products for efficient loading and unloading.

2. Manufacturing In production lines, vertical guide rollers assist in the automation of assembly processes, ensuring that components are aligned correctly for further processing.

3. Construction In cranes and hoisting systems, these rollers are crucial for guiding cables and maintaining structural integrity during lifting operations.

4. Transportation Vertical guide rollers are used in elevators and escalators, ensuring smooth movement while supporting the weight being carried.

5. Textile and Paper Industries Guiding fabrics and rolls of paper through various stages of production, vertical guide rollers ensure consistency and prevent material snags.

Features of Vertical Guide Rollers

The performance of vertical guide rollers can be influenced by several key features

vertical guide rollers

- Material Composition Typically made from high-quality steel or polymer compounds, the material dictates the roller's ability to withstand wear, load, and environmental factors.

- Bearing Type The incorporation of appropriate bearing systems improves the rotation efficiency of the rollers. Common types include ball bearings and roller bearings, each suited for different load capacities and speed requirements.

- Size and Dimensions The size of the rollers is designed based on the specific requirements of the application, including the weight and size of the materials being guided.

- Load Capacity It's essential for vertical guide rollers to be rated for the specific load capacity they will encounter during operation. This ensures safety and longevity.

Advantages of Using Vertical Guide Rollers

Incorporating vertical guide rollers into machinery offers numerous benefits

1. Enhanced Efficiency By ensuring proper alignment, vertical guide rollers reduce friction and wear, leading to smoother operation and increased productivity.

2. Reduced Downtime With fewer mechanical failures due to misalignment, the overall downtime for maintenance is minimized, enhancing operational efficiency.

3. Versatility These rollers can be customized for various applications, making them versatile components suitable for different industries.

4. Cost-Effectiveness While initial costs may vary, the long-term savings from reduced wear and tear, as well as improved efficiency, can make vertical guide rollers a sound investment.

Conclusion

Vertical guide rollers play a pivotal role in modern industrial operations. Their ability to provide reliable guidance and support is vital in maintaining the efficiency and functionality of machinery across various sectors. As technology advances, the design and materials used in vertical guide rollers are likely to evolve, offering even greater performance and reliability. Whether in material handling, manufacturing, or construction, these components remain indispensable for ensuring smooth and effective operations. Understanding their function, applications, and benefits is essential for industries looking to optimize their processes and enhance productivity.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025