Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

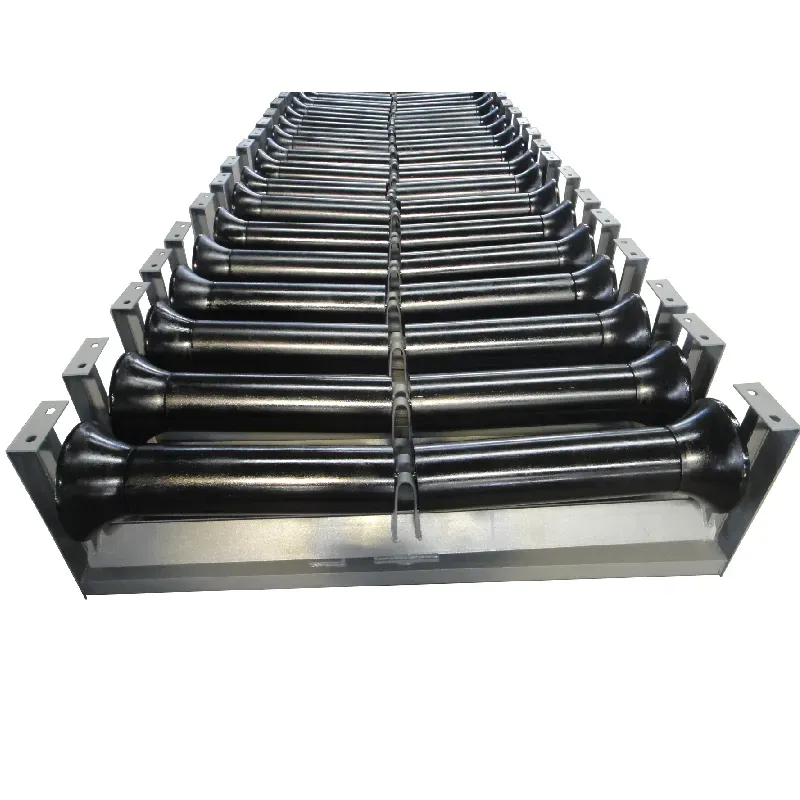

Zulu vee return idler

Understanding VEE Return Idler A Comprehensive Overview

In today’s technologically driven world, understanding the myriad components that constitute complex systems is key to optimizing performance and efficiency. One such component, often overlooked yet crucial, is the VEE return idler. This term may be unfamiliar to many, but its significance becomes apparent in the context of various mechanical systems, particularly in the realm of automotive and industrial equipment. This article aims to elucidate what a VEE return idler is, its functions, and the importance it holds in systems where it is implemented.

What is a VEE Return Idler?

The VEE return idler is a specialized component used primarily in conveyor systems, belting applications, and mechanical drives. It is designed to guide and support the return path of a conveyor or belt, ensuring that the system runs smoothly and efficiently. The term VEE refers to the shape of the groove or channel in which the belt resides. This design helps to maintain alignment and reduce slippage, contributing to the overall reliability of the system.

Key Functions of the VEE Return Idler

1. Support and Stability One of the primary functions of the VEE return idler is to provide support to the belt as it travels back to the drive pulley. A well-designed idler keeps the belt aligned and reduces sagging, which can lead to unnecessary wear and tear.

2. Reducing Friction The VEE groove minimizes the contact surface area between the idler and the belt. This reduction in contact friction allows for smoother operation and enhances the overall efficiency of the conveyor system.

3. Maintaining Tension Proper tension in a belt system is vital for its performance. The VEE return idler helps maintain consistent tension across the belt, preventing slippage and ensuring that the materials being transported are moved effectively.

vee return idler

4. Noise Reduction As with any mechanical system, noise can be a significant issue. The design of the VEE return idler can help dampen sound, leading to quieter operations—an essential consideration in industrial settings.

5. Protection from Environmental Factors Conveyor systems often operate in harsh environments. The VEE return idler is designed to withstand wear from dust, moisture, and other contaminants, thus extending its lifespan and reliability.

Importance of VEE Return Idler in Industry

In industries where conveyor systems are paramount—such as mining, logistics, and manufacturing—the role of the VEE return idler cannot be overstated. It directly impacts the efficiency of material handling processes and can lead to significant cost savings. A malfunctioning idler can result in system downtime, decreased productivity, and increased maintenance costs.

Furthermore, as industries evolve and automation becomes more prevalent, the demand for efficient and reliable conveyor systems rises. The integration of high-quality components like the VEE return idler can play a critical role in meeting the rigorous demands of modern manufacturing processes, fostering both innovation and growth.

Conclusion

The VEE return idler may not be the most glamorous element of industrial systems, but its role is instrumental in ensuring the seamless operation of conveyor belts and similar mechanisms. By providing support, reducing friction, and maintaining tension, these components contribute to the overall efficiency and reliability of various mechanical systems. As industries continue to innovate and expand, understanding the importance of components like the VEE return idler will be vital for engineers, designers, and operators alike. Investing in quality idlers is not just a matter of functionality; it is a step towards ensuring the longevity and effectiveness of the entire system.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025