Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu V-Belt Idler Pulleys Classified by Dimension and Size for Efficient Application

Understanding V-Belt Idler Pulleys by Size

V-belt idler pulleys play a crucial role in the efficiency and performance of various mechanical systems, especially in automotive and industrial applications. An idler pulley helps to maintain tension in the belt system, guiding the belt without transferring any mechanical power. Understanding the sizes and specifications of V-belt idler pulleys is essential for ensuring proper alignment, optimal performance, and longevity of the equipment.

The Importance of Size in V-Belt Idler Pulleys

The size of a V-belt idler pulley influences its compatibility with the existing belt drive system. Pulleys come in various diameters and widths, which must correspond to the dimensions of the V-belt being used. The correct size helps maintain belt tension and alignment, reducing the risk of slippage or excessive wear. Choosing an idler pulley that is too small can lead to improper tension, escalating the chances of belt failure, while overly large pulleys may cause the belt to track poorly, resulting in inefficient operation.

Measuring Idler Pulleys

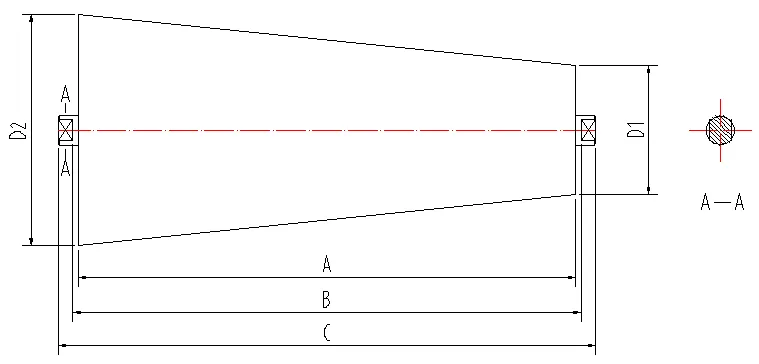

When selecting a V-belt idler pulley, there are a few key measurements to consider

1. Diameter The diameter of the pulley is a significant factor, affecting how it interacts with the belt. Larger pulleys can provide smoother operation but may require a more powerful motor due to their ability to increase belt speed.

v belt idler pulleys by size

2. Width The width of the pulley must align with the width of the V-belt. A mismatch can lead to uneven wear and decreased efficiency. The wider the pulley, the more surface area it has to grab onto the belt, ensuring better grip and stability.

3. Bore Size The bore refers to the central hole in the pulley, which fits onto the shaft. Ensuring that the bore size matches the shaft diameter is vital for secure installation and operational efficiency.

4. Frame Type Idler pulleys are often available in various frame types, including fixed and adjustable frames. Fixed idlers provide consistent tension but rigidity, while adjustable frames allow for tension changes as the belt stretches over time.

Material Considerations

The material of the V-belt idler pulley also plays an essential role in its performance. Common materials include plastic, steel, and aluminum. Steel and aluminum provide durability and strength, making them ideal for heavy-duty applications, while plastic is lightweight and can be better suited for lighter loads or environments where corrosion is a concern.

Conclusion

In conclusion, understanding V-belt idler pulleys by size is critical in ensuring optimal performance in mechanical systems. By paying attention to the diameter, width, bore size, and material, users can select the right idler pulley that meets their specific needs. Proper selection leads to improved belt tension, decreased wear, and enhanced operational efficiency. Whether for automotive repair or industrial machinery maintenance, knowledge of V-belt idler pulley sizing empowers technicians to achieve reliable and efficient machinery operation. Always consult with a professional or refer to manufacturer specifications when in doubt for the best results.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025