Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu v belt drive pulley

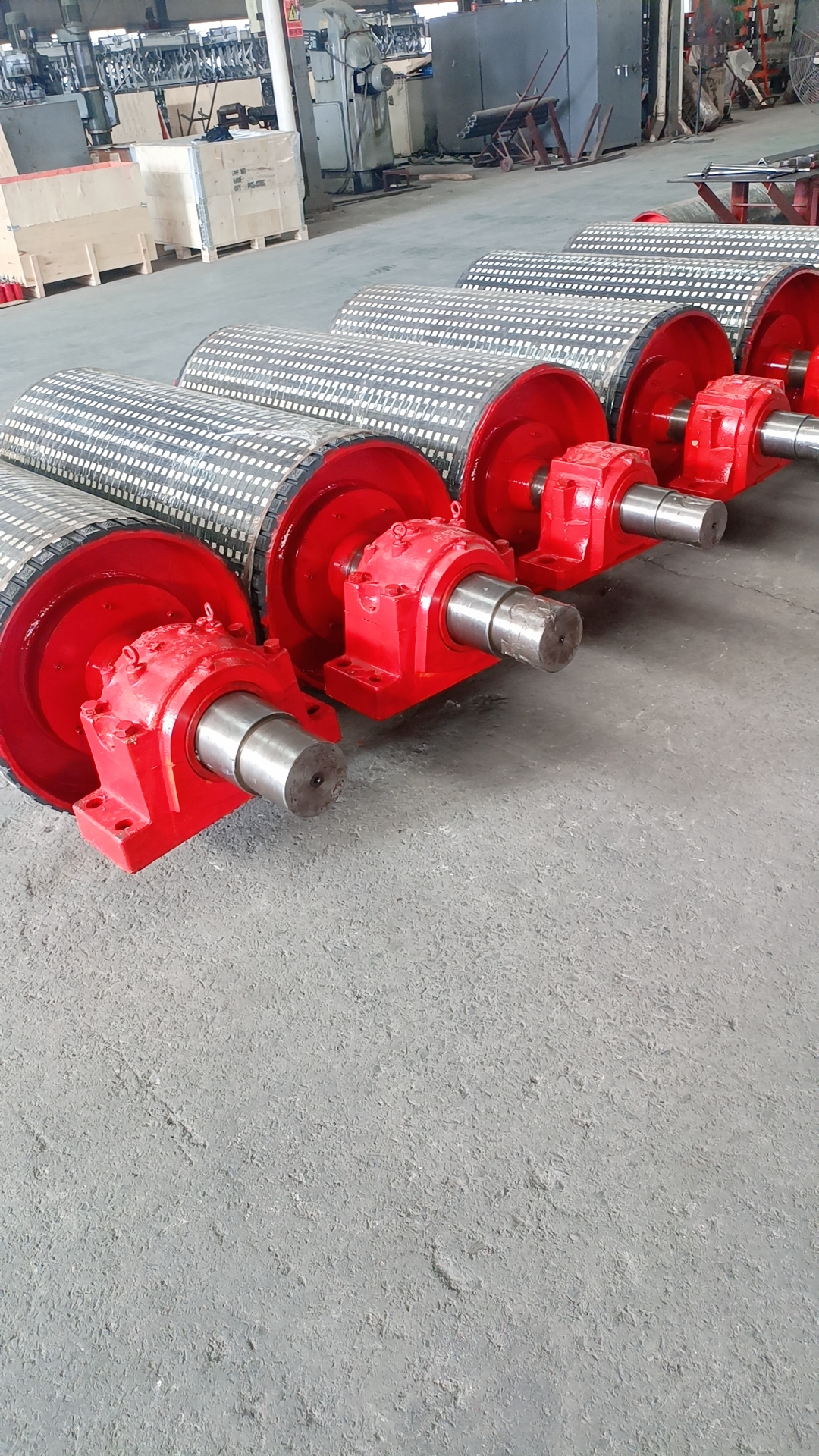

Understanding V-Belt Drive Pulleys A Comprehensive Overview

V-belt drive pulleys are essential components in various mechanical systems, widely used in industries ranging from manufacturing to automotive applications. Their role in power transmission and motion control makes them a fundamental aspect of mechanical engineering. This article delves into the components, benefits, and applications of V-belt drive pulleys, providing a comprehensive understanding of their significance in everyday machinery.

What Are V-Belt Drive Pulleys?

V-belt drive pulleys are specially designed wheels that feature a V shaped groove on their outer edge. This design allows for a secure fit with V-belts—flexible loops of rubber or synthetic materials that transmit power between the pulleys. The V shape of the belt mechanism allows for increased friction, reducing slippage and ensuring efficient power transfer from one pulley to another.

Key Components

1. Pulleys The primary component, usually made of metal or durable plastic, depending on the application's requirements. They come in various sizes and diameters, allowing for flexibility in speed and torque adjustments.

2. V-Belts These are the flexible belts that traverse the grooves of the pulleys. They can vary in width and length, and their selection is critical for optimal performance.

3. Tensioners These components maintain the ideal tension in the belt to prevent slippage and wear over time. Proper tension is essential for the longevity of both the belt and the pulleys.

4. Bearings Located at the center of the pulleys, bearings reduce friction and enable smoother rotation, increasing the efficiency of the drive mechanism.

Advantages of V-Belt Drive Pulleys

V-belt drive pulleys offer numerous benefits, making them a popular choice in many applications

v belt drive pulley

2. Versatility They can be used in a wide range of speeds and torque conditions, making them suitable for varied applications, from simple machines to complex systems.

3. Low Maintenance Compared to other drive systems, V-belt drives require less maintenance. With proper installation and alignment, these systems can operate effectively for extended periods.

4. Shock Absorption V-belts can absorb shocks and vibrations in the system, helping to protect other components and prolonging their lifespan.

5. Cost-Effectiveness Generally, V-belt pulley systems are less expensive than other forms of power transmission, making them a cost-effective solution for many businesses.

Applications of V-Belt Drive Pulleys

V-belt drive pulleys are found in a plethora of applications across various sectors

- Automotive Industry From powering alternators to air conditioning compressors, V-belt systems play a critical role in the operation of most vehicles.

- Manufacturing and Machinery Many industrial machines, such as conveyor belts, lathes, and milling machines, utilize V-belt systems to transfer power efficiently.

- Agriculture Tractors and other agricultural machinery often rely on V-belt drive pulleys to ensure smooth operation of various attachments and implements.

- HVAC Systems V-belt drives are frequently used in fans and blowers, providing a reliable means of transferring power in heating, ventilation, and air conditioning systems.

Conclusion

In conclusion, V-belt drive pulleys are indispensable components in the realm of mechanical systems, offering efficiency, versatility, and cost-effectiveness across multiple industries. Understanding their design, components, and applications can help engineers and technicians optimize their use, ensuring the smooth operation of machinery and equipment. As innovations continue to evolve, the relevance and application of V-belt drive pulleys will undoubtedly persist, solidifying their place in mechanical engineering.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025