Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu v belt drive pulley

Understanding V-Belt Drive Pulley Systems

V-belt drive pulley systems play a crucial role in various mechanical applications, providing a reliable means of power transmission in numerous industries. These systems are widely used in machinery ranging from industrial equipment to household appliances, and understanding their components and functionality is essential for effective maintenance and operation.

What is a V-Belt Drive Pulley?

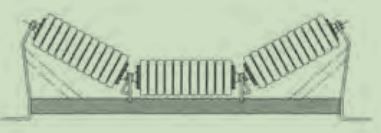

A V-belt drive usually consists of a pair of pulleys connected by a V-shaped belt. The pulleys are typically mounted on shafts and rotate to transmit power from one shaft to another. The V-shape of the belt serves several purposes it allows for better grip between the belt and the pulley, reduces slippage, and accommodates the misalignment that may occur during operation. The design also promotes efficient energy transfer, making V-belt drives a popular choice for various applications.

Key Components

1. Pulleys The pulleys are the central components in a V-belt drive system. Each pulley has a groove that fits snugly around the V-belt. They can differ in size, influencing the speed and torque. Larger pulleys will generally result in higher torque and lower speed, whereas smaller ones will do the opposite.

2. V-Belts These belts are manufactured from durable materials, including rubber composites and fabric layers, to withstand wear and tear. They come in various sizes and shapes, designed for different load capacities and machine requirements. The V-belt's cross-section allows it to operate under tension while maintaining its shape, ensuring consistent performance.

3. Tensioners and Idlers In many systems, tensioners and idler pulleys help maintain proper tension in the V-belt, ensuring optimal contact with the drive pulleys. This maintenance of tension is vital to prevent slippage and ensure longevity.

Advantages of V-Belt Drives

V-belt drives offer numerous advantages, making them a preferred choice in many applications

v belt drive pulley

- High Efficiency V-belt drives can achieve an efficiency rating of around 95% or higher under the right conditions, minimizing energy losses during power transmission.

- Simplicity The configuration of a V-belt drive is straightforward, making installation and maintenance easy. This simplicity translates to lower labor costs and quicker repairs.

- Noise Reduction Compared to chain drives, V-belt drives typically operate more quietly, a significant advantage in environments where noise levels must be kept low.

- Shock Absorption V-belt drives can absorb shock loads effectively, protecting the machinery from abrupt changes in power transmission. This characteristic helps to extend the lifespan of both the belt and the associated equipment.

Applications

V-belt drives are pervasive across various industries. One of the most common applications is in agricultural machinery, such as tractors and combine harvesters, where consistent power transfer is vital for efficient operation. They are also found in HVAC systems for driving fans and pumps, in automotive engines to run alternators, and in manufacturing equipment for conveyor systems.

Maintenance of V-Belt Drive Systems

To ensure reliability and extend the lifespan of V-belt drive systems, regular maintenance is essential. This includes checking the tension of the belts, inspecting for wear or damage, and ensuring that the pulleys are aligned correctly. In addition, proper lubrication of moving parts can help prevent friction and prolong the life of the system.

Conclusion

V-belt drive pulley systems are integral to the performance of a vast array of machinery and equipment. Their design offers a unique blend of efficiency, simplicity, and durability. Understanding how they work and how to maintain them can lead to enhanced operational performance and reduced downtime. As industries continue to evolve, the demand for reliable power transmission solutions will ensure that V-belt drives remain a fundamental component of mechanical engineering.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025