Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu v belt drive pulley

V-Belt Drive Pulleys A Comprehensive Overview

V-belt drive pulleys are essential components widely used in mechanical systems for the transmission of power. Their design and functionality play a crucial role in various applications, ranging from industrial machinery to automotive engines. This article explores the key aspects of V-belt drive pulleys, including their structure, operation, advantages, applications, and maintenance considerations.

Structure and Design

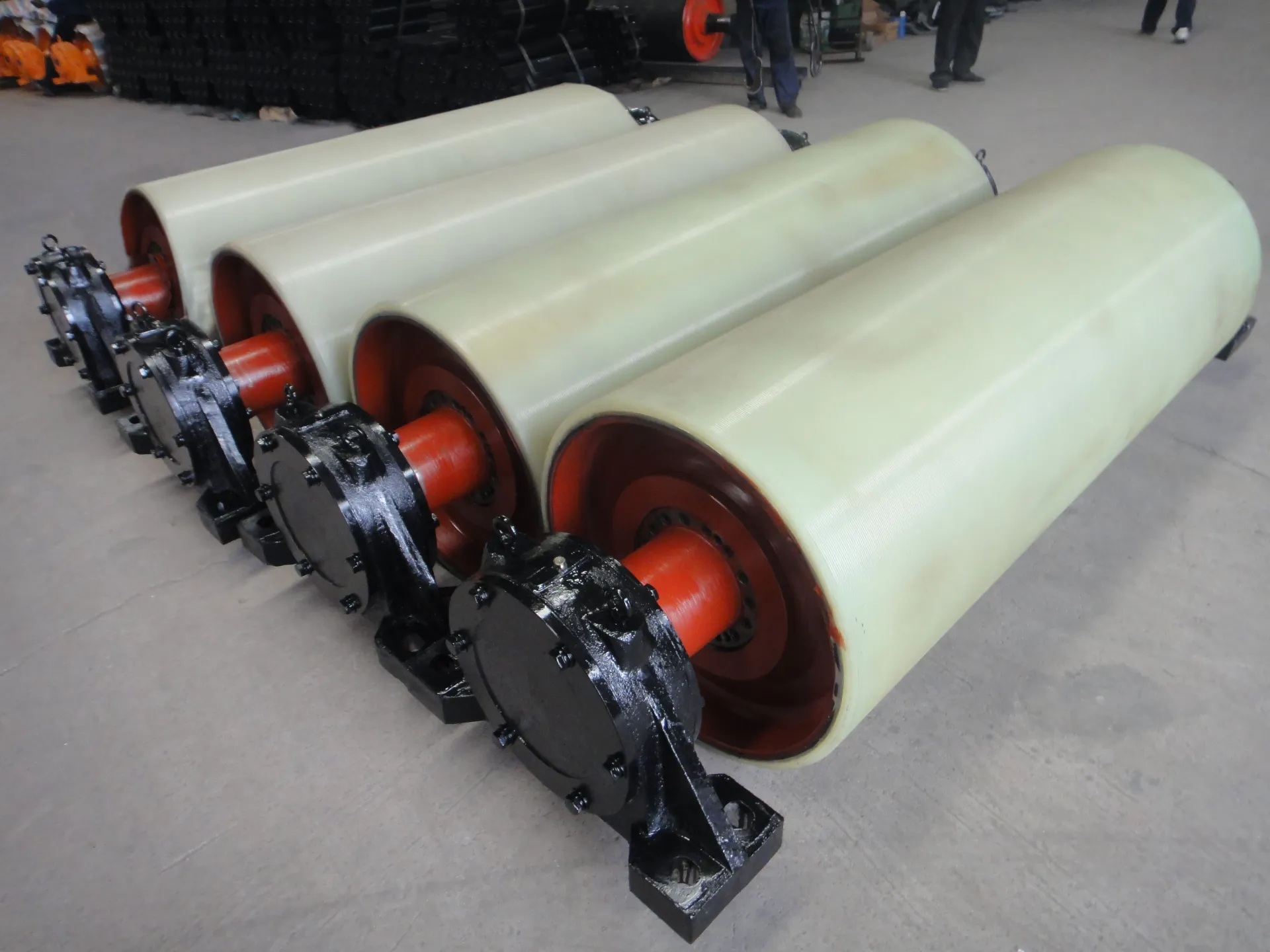

A V-belt drive pulley typically features a distinct V-shaped groove along its circumference. This design enables the belt to fit snugly within the pulley, enhancing friction and consequently improving power transmission efficiency. Pulleys come in various materials, including cast iron, aluminum, and plastic, depending on the application's demands. The choice of material greatly influences the pulley’s strength, durability, and weight.

The size and diameter of the pulleys are also vital in determining the speed and torque output of the system. When two V-belt pulleys are used in tandem—one as a driving pulley connected to a motor and the other as a driven pulley connected to a load—their diameters dictate the ratio by which speed and torque are altered. Understanding this relationship is essential for engineers and technicians as they design and implement power transmission systems.

Operation and Functionality

The primary function of a V-belt drive pulley is to transfer power from a driving shaft to a driven shaft through the use of a V-belt. The V-belt wraps around the pulley grooves, and as the driving pulley rotates, it causes the belt to move. This movement translates into kinetic energy that is transferred to the driven pulley, thereby powering connected machinery or components.

One of the key advantages of V-belt systems is their ability to handle moderate power loads and to operate in high-speed environments while maintaining a compact and lightweight design. They provide a reliable means of transferring power with minimal slip due to their high frictional contact surface area. Additionally, they are known for their quiet operation compared to other power transmission methods like chain drives.

Advantages of V-Belt Drive Pulleys

V-belt drive pulleys offer numerous benefits, including

1. Efficiency The V-belt's unique design minimizes slippage and enhances power transmission efficiency, making it an ideal choice for various applications.

v belt drive pulley

2. Versatility They can be used in a wide array of machinery, from agricultural equipment to conveyor systems, providing flexibility in design.

3. Cost-Effectiveness V-belt systems are generally less expensive to manufacture and install than other power transmission systems, making them a popular choice for many industries.

4. Ease of Maintenance V-belt drive systems typically require less maintenance than chain drives. When a belt wears out, it can be easily replaced without the need for extensive disassembly of the machinery.

5. Load Absorption The elasticity of the V-belt allows it to absorb shocks and vibrations, protecting the machinery and extending its lifespan.

Applications

V-belt drive pulleys are prevalent in various sectors, including

- Manufacturing Used in conveyor systems, lathes, and milling machines to transmit power from electric motors to drive shafts. - Automotive Found in engine systems driving alternators, water pumps, and air conditioning compressors. - Agriculture Employed in tractors and harvesting equipment to power attachments and implements. - HVAC Systems Utilized in fans and blowers for ventilation and cooling applications.

Maintenance Considerations

To ensure optimal performance and longevity, regular maintenance of V-belt drive systems is essential. This includes checking for wear and tear of the belts, ensuring proper tension, and inspecting the pulleys for signs of damage or misalignment. Keeping the drive components clean from dust and debris can also prevent unnecessary wear and improve efficiency.

Conclusion

V-belt drive pulleys play a vital role in modern mechanical systems by providing a reliable and efficient means of power transmission. Their robust design, combined with the numerous advantages they offer, makes them a preferred choice in various applications. By understanding their structure, operation, and maintenance needs, engineers and technicians can optimize their use and ensure maximum performance in their respective applications. As industries continue to evolve, the adaptability and reliability of V-belt drive pulleys will remain crucial in meeting the demands of advanced machinery and systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025