Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu v belt tensioner pulley

Understanding V-Belt Tensioner Pulleys Their Importance and Functionality

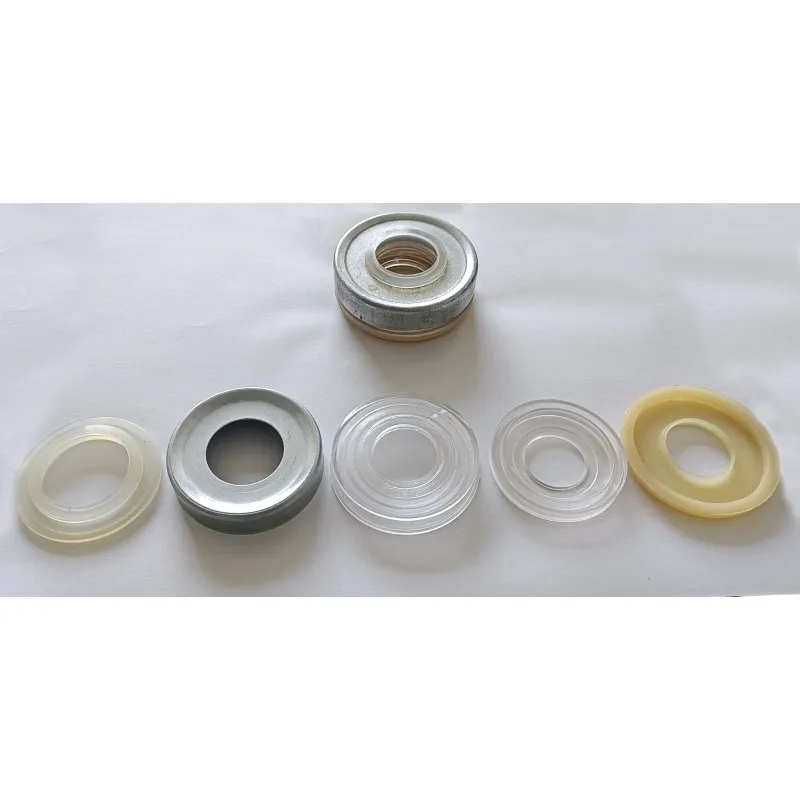

The V-belt tensioner pulley is a critical component in many automotive and industrial applications. This versatile device plays a crucial role in maintaining the appropriate tension in V-belts, which are used for transmitting power between different parts of a machine or engine. Without a properly functioning tensioner pulley, the efficiency of the belt system can diminish, leading to excessive wear, decreased performance, and potential system failure.

Understanding V-Belt Tensioner Pulleys Their Importance and Functionality

One of the main advantages of using a V-belt tensioner pulley is its ability to compensate for changes in belt length and elasticity. As V-belts age, they can lose flexibility, resulting in reduced tension. The tensioner pulley is spring-loaded, allowing it to move in response to belt tension fluctuations. This dynamic adjustment is vital for maintaining the efficiency of the drive system, ensuring that power is transmitted smoothly and effectively.

v belt tensioner pulley

Moreover, V-belt tensioners come in two main types manual and automatic. Manual tensioners require routine adjustments by the operator, while automatic tensioners self-adjust based on the inherent characteristics of the belt system. Automatic tensioners are often preferred in modern applications for their convenience and reliability, as they require less maintenance over time.

The materials used in constructing V-belt tensioner pulleys are also worth noting. Typically made from high-strength plastics or metals like aluminum, these pulleys are designed to withstand considerable forces and harsh operating conditions. Their bearings are engineered to reduce friction and wear, further enhancing their lifespan and performance.

Regular maintenance of the V-belt tensioner pulley is essential for the longevity of both the pulley and the belt. Signs of wear, such as unusual noises, belt slipping, or visible damage to the pulley, may indicate that the tensioner needs replacement. It is a good practice to inspect the tensioner pulley during routine vehicle maintenance to prevent unforeseen breakdowns and ensure optimal performance.

In conclusion, the V-belt tensioner pulley plays a significant role in the efficient operation of many mechanical systems. By automatically maintaining the correct belt tension, it helps prevent slippage and wear, thereby enhancing the overall performance and longevity of the system. Understanding its function and maintaining it properly can lead to smoother operation and reduced repair costs over time. Whether in automotive engines or industrial machinery, the importance of the V-belt tensioner pulley cannot be overstated. Proper care and timely replacement will ensure that machines remain operational and efficient for years to come.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025