Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 19, 2025 11:26

Back to list

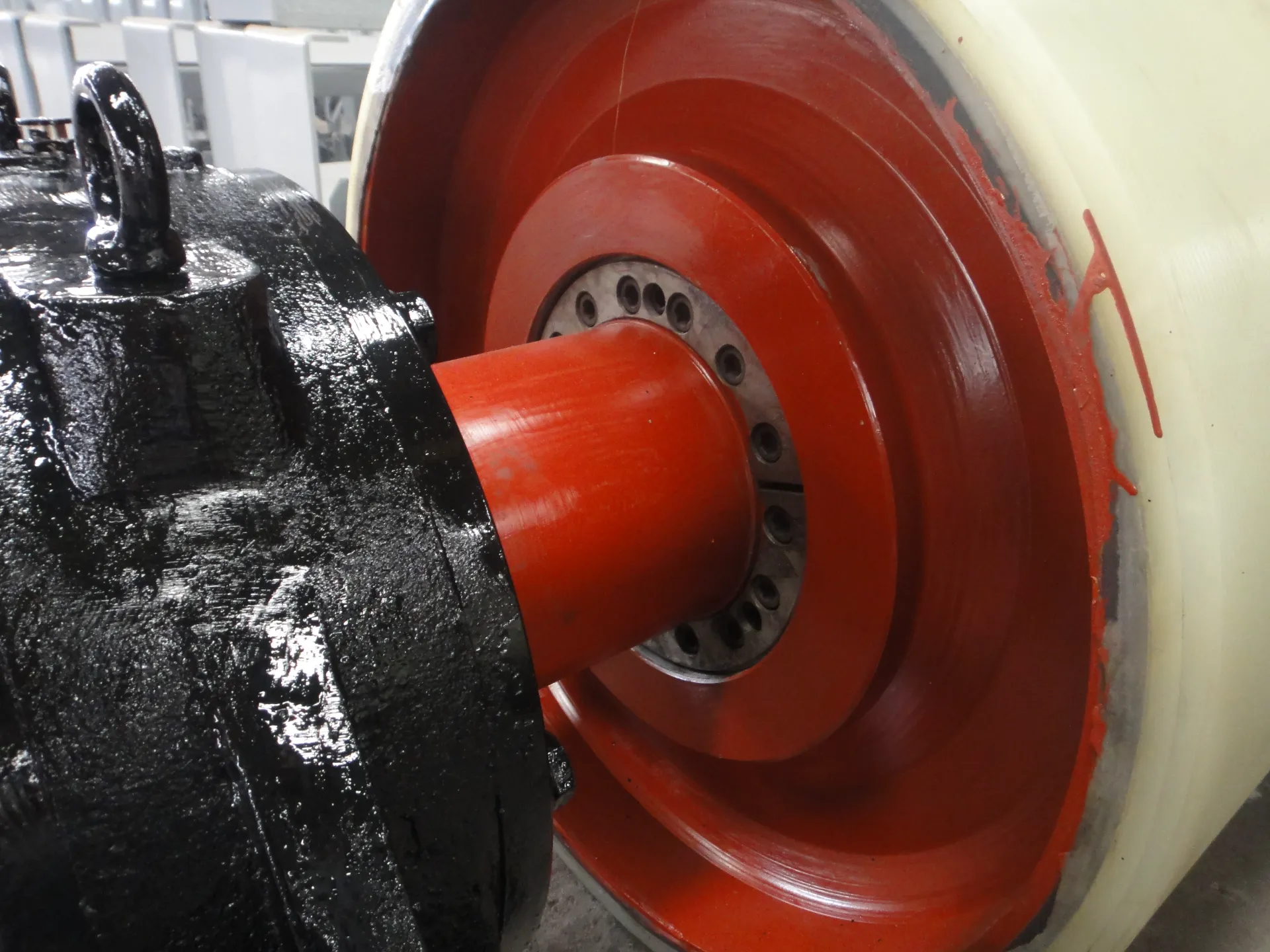

Polyurethane Pulley(Polyurethane Lagging Pulley)

Urethane pulleys have emerged as indispensable components in various industrial sectors, engendering a profound impact with their unique properties and applications. Known for their durability and resistance to corrosion, these pulleys have transformed operational efficiencies across industries ranging from manufacturing to aerospace. Through this exploration, the unparalleled benefits and uses of urethane pulleys are detailed, showcasing their distinctive contributions to industry advancements.

Authoritativeness in the domain of urethane pulleys is marked by their widespread adoption in cutting-edge technologies and industries. Aerospace, automotive, and robotics sectors, among others, have incorporated urethane pulleys to optimize performance and safety. In aviation, for instance, these pulleys play a critical role in ensuring smooth and reliable operations of various mechanisms. Their lightweight nature contributes to fuel efficiency, a critical factor in modern aviation technology. Similarly, in the automotive industry, urethane pulleys facilitate innovative solutions in engine designs and transmission systems, thereby enhancing vehicle efficiency and performance. Trustworthiness in urethane pulleys is further reinforced through rigorous testing and adherence to international standards. These pulleys undergo a series of exhaustive evaluations to ensure they meet industry-specific requirements, guaranteeing they perform exceptionally even under the most demanding conditions. Clients relying on these critical components place immense trust in their consistent performance, a trust earned through years of proven track records and technological advancements in urethane chemistry. In conclusion, the multifaceted advantages of urethane pulleys underscore their essential role in modern industrial applications. Their combination of durability, customization, noise reduction, and compliance with safety standards makes them an indispensable asset across various fields. As industries continue to evolve, the demand for reliable and efficient components like urethane pulleys is set to rise, cementing their status as a cornerstone in the pursuit of operational excellence. The exploration of urethane pulleys unveils a narrative of innovation, quality, and customer satisfaction, solidifying their place as a valued choice among informed industry professionals.

Authoritativeness in the domain of urethane pulleys is marked by their widespread adoption in cutting-edge technologies and industries. Aerospace, automotive, and robotics sectors, among others, have incorporated urethane pulleys to optimize performance and safety. In aviation, for instance, these pulleys play a critical role in ensuring smooth and reliable operations of various mechanisms. Their lightweight nature contributes to fuel efficiency, a critical factor in modern aviation technology. Similarly, in the automotive industry, urethane pulleys facilitate innovative solutions in engine designs and transmission systems, thereby enhancing vehicle efficiency and performance. Trustworthiness in urethane pulleys is further reinforced through rigorous testing and adherence to international standards. These pulleys undergo a series of exhaustive evaluations to ensure they meet industry-specific requirements, guaranteeing they perform exceptionally even under the most demanding conditions. Clients relying on these critical components place immense trust in their consistent performance, a trust earned through years of proven track records and technological advancements in urethane chemistry. In conclusion, the multifaceted advantages of urethane pulleys underscore their essential role in modern industrial applications. Their combination of durability, customization, noise reduction, and compliance with safety standards makes them an indispensable asset across various fields. As industries continue to evolve, the demand for reliable and efficient components like urethane pulleys is set to rise, cementing their status as a cornerstone in the pursuit of operational excellence. The exploration of urethane pulleys unveils a narrative of innovation, quality, and customer satisfaction, solidifying their place as a valued choice among informed industry professionals.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS