Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 15, 2025 01:02

Back to list

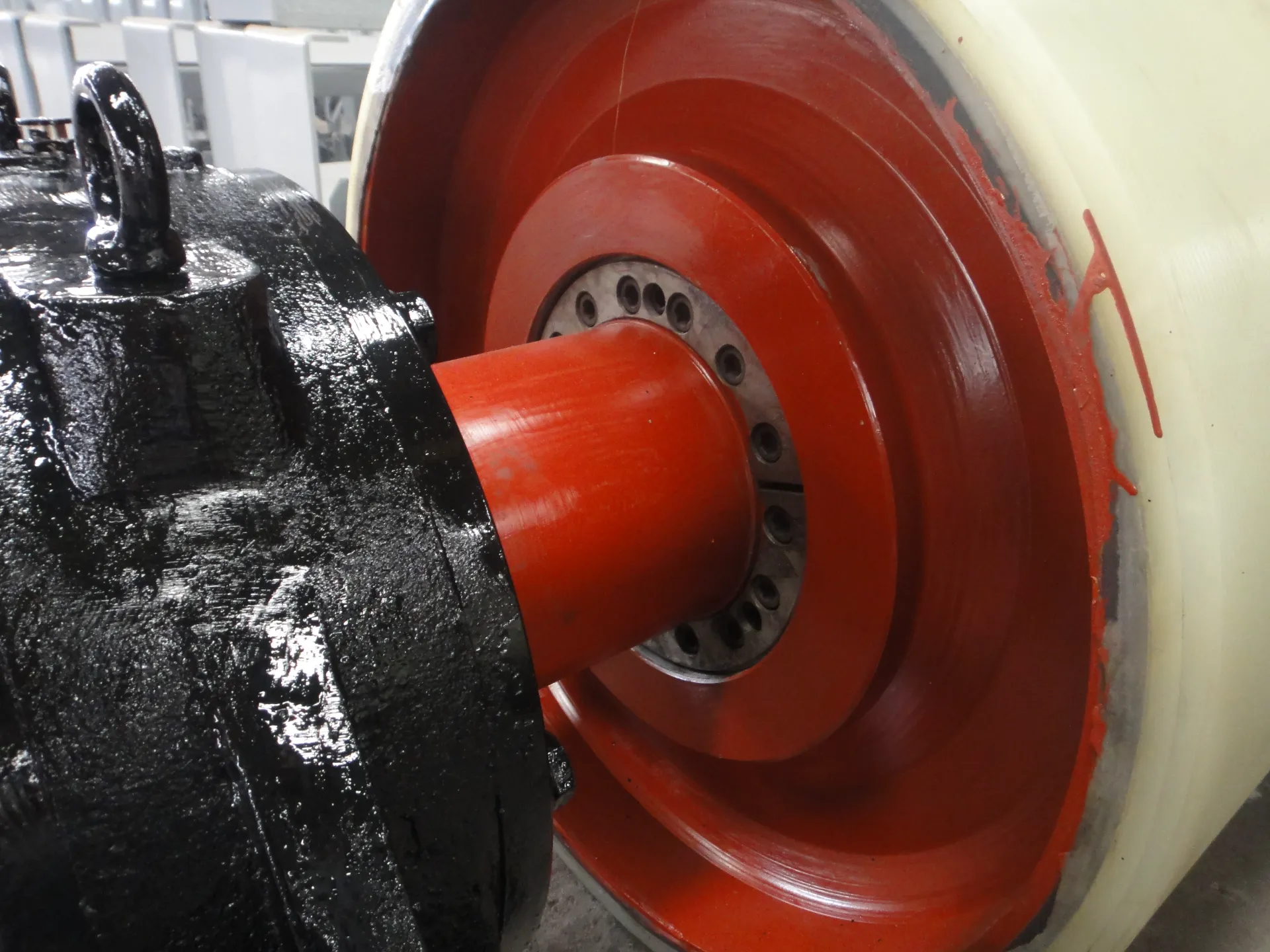

urethane pulley

Urethane pulleys have quietly revolutionized the world of machinery components, offering unparalleled performance, durability, and versatility. Companies across numerous industries have embraced this innovation for their machinery needs, which speaks volumes about their effectiveness and reliability.

From an engineering perspective, the light weight of urethane pulleys ensures less strain on machinery, which translates to better fuel efficiency and reduced wear on motor components. Unlike metal pulleys, which add substantial weight and necessitate more energy for movement, urethane options allow for smoother and more efficient operations. Specialists in mechanical design underscore the pivotal role of urethane pulleys in extending the life span of machinery and advancing sustainable industrial practices. Moreover, the compatibility of urethane pulleys with a variety of shafts and hubs further highlights their practicality. They can be easily integrated into existing machine designs or installed in new machinery with little to no modifications needed. Businesses investing in urethane pulleys appreciate this seamless integration, which avoids costly redesigns and installations, paving the way for immediate benefits in operational performance. It is also crucial to address the eco-friendly aspects of urethane pulleys. As industries move towards sustainability, urethane's recyclable nature and lower carbon footprint render them an attractive alternative to traditional materials. This aspect aligns businesses with increasingly rigorous environmental standards and regulations, reinforcing the corporate responsibility towards a greener planet. In conclusion, urethane pulleys present a compelling combination of durability, versatility, efficiency, and eco-friendliness, making them an invaluable asset for contemporary industrial applications. Their ability to withstand challenging environments, coupled with cost-efficiency and ease of integration, positions them as a leader in the pulley market. As industries continue to evolve and seek reliable, innovative solutions, the demand for urethane pulleys is poised for growth, cementing their status as a cornerstone in the realm of machine componentry.

From an engineering perspective, the light weight of urethane pulleys ensures less strain on machinery, which translates to better fuel efficiency and reduced wear on motor components. Unlike metal pulleys, which add substantial weight and necessitate more energy for movement, urethane options allow for smoother and more efficient operations. Specialists in mechanical design underscore the pivotal role of urethane pulleys in extending the life span of machinery and advancing sustainable industrial practices. Moreover, the compatibility of urethane pulleys with a variety of shafts and hubs further highlights their practicality. They can be easily integrated into existing machine designs or installed in new machinery with little to no modifications needed. Businesses investing in urethane pulleys appreciate this seamless integration, which avoids costly redesigns and installations, paving the way for immediate benefits in operational performance. It is also crucial to address the eco-friendly aspects of urethane pulleys. As industries move towards sustainability, urethane's recyclable nature and lower carbon footprint render them an attractive alternative to traditional materials. This aspect aligns businesses with increasingly rigorous environmental standards and regulations, reinforcing the corporate responsibility towards a greener planet. In conclusion, urethane pulleys present a compelling combination of durability, versatility, efficiency, and eco-friendliness, making them an invaluable asset for contemporary industrial applications. Their ability to withstand challenging environments, coupled with cost-efficiency and ease of integration, positions them as a leader in the pulley market. As industries continue to evolve and seek reliable, innovative solutions, the demand for urethane pulleys is poised for growth, cementing their status as a cornerstone in the realm of machine componentry.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS