Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 13, 2025 15:39

Back to list

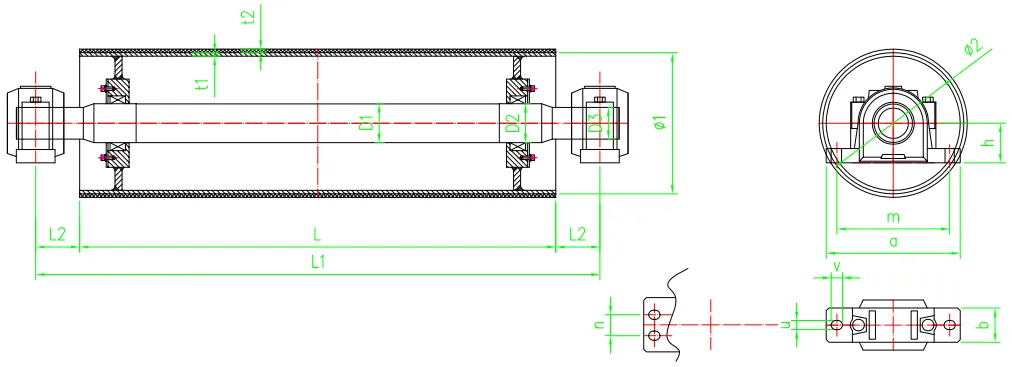

types of conveyor idlers

In the realm of material handling, conveyor idlers play a pivotal role in ensuring efficiency and reliability. Understanding the different types of conveyor idlers is crucial for optimizing operations, enhancing productivity, and ensuring safety in industrial environments.

Impact idlers are strategically placed at conveyor loading and transfer points where the risk of damage to the belt is highest due to material impact. Outfitted with resilient components like rubber discs, these idlers absorb and mitigate the force of heavy loads. To assure maximum longevity and service life of conveyor systems, these idlers are frequently deployed in high-impact scenarios common to the construction and aggregate processing sectors. Offset idlers offer a unique structural advantage, with each roller positioned to counterbalance each other. This design minimizes material buildup on the rollers and simplifies maintenance. While they might not be necessary for every operation, offset idlers are invaluable in conditions prone to sticky materials or extreme weather, preserving the efficiency of the conveyor system. Additionally, garland idlers are a flexible option formed by linking several rollers on chains or pivoted connections. This configuration offers high load compensation and exceptional adaptability across varied terrain, making them ideal for long, undulating conveyor routes such as those in large construction projects or mining operations requiring versatility. In conclusion, selecting the appropriate type of idler depends on several factors, including the type of material, load capacity, and application environment. The precise choice of idlers directly influences the conveyor system's efficiency, reliability, and lifespan. Investing in the right conveyor components not only enhances operational throughput but also fosters a safer and more sustainable execution of material handling tasks. Understanding these components’ intricacies not only empowers operational excellence but also solidifies a company’s standing as a leader in industrial innovation and efficiency.

Impact idlers are strategically placed at conveyor loading and transfer points where the risk of damage to the belt is highest due to material impact. Outfitted with resilient components like rubber discs, these idlers absorb and mitigate the force of heavy loads. To assure maximum longevity and service life of conveyor systems, these idlers are frequently deployed in high-impact scenarios common to the construction and aggregate processing sectors. Offset idlers offer a unique structural advantage, with each roller positioned to counterbalance each other. This design minimizes material buildup on the rollers and simplifies maintenance. While they might not be necessary for every operation, offset idlers are invaluable in conditions prone to sticky materials or extreme weather, preserving the efficiency of the conveyor system. Additionally, garland idlers are a flexible option formed by linking several rollers on chains or pivoted connections. This configuration offers high load compensation and exceptional adaptability across varied terrain, making them ideal for long, undulating conveyor routes such as those in large construction projects or mining operations requiring versatility. In conclusion, selecting the appropriate type of idler depends on several factors, including the type of material, load capacity, and application environment. The precise choice of idlers directly influences the conveyor system's efficiency, reliability, and lifespan. Investing in the right conveyor components not only enhances operational throughput but also fosters a safer and more sustainable execution of material handling tasks. Understanding these components’ intricacies not only empowers operational excellence but also solidifies a company’s standing as a leader in industrial innovation and efficiency.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS