Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu types of conveyor belt pulleys

Understanding the Different Types of Conveyor Belt Pulleys

Conveyor belt systems are crucial in various industries, including manufacturing, logistics, mining, and food processing. At the heart of these systems are conveyor belt pulleys, which play a vital role in driving the belt and ensuring efficient material handling. This article delves into the different types of conveyor belt pulleys, their functions, and their significance in optimizing conveyor performance.

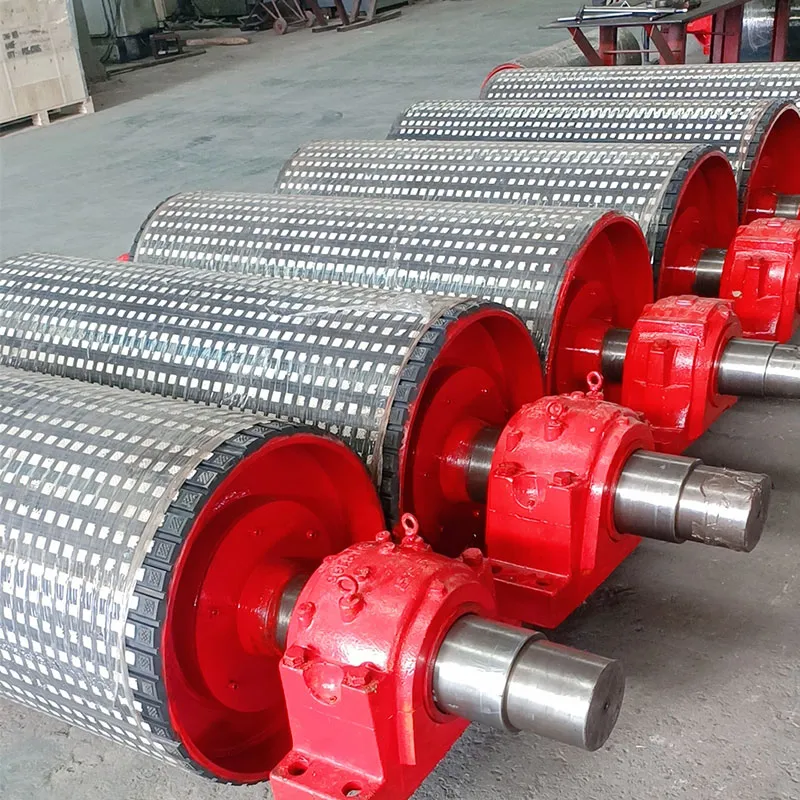

1. Drive Pulleys

The drive pulley is the most critical component of a conveyor system. It is responsible for providing the necessary power to move the conveyor belt. Also known as the head pulley, this type of pulley is typically located at the discharge end of the conveyor. A drive pulley can be powered by an electric motor, allowing it to efficiently transport materials over varying distances.

Drive pulleys are designed with a textured surface to enhance friction between the pulley and the conveyor belt, preventing slippage. They come in different configurations, including smooth, rubberized, or crowned shapes, catering to different operational requirements and load capacities.

2. Idler Pulleys

Idler pulleys are used to support and guide the conveyor belt, maintaining its alignment and tension throughout the system. These pulleys do not drive the belt but are essential for minimizing belt sagging and reducing wear and tear. Idler pulleys are typically located at various points along the conveyor, including the return side, where they help maintain the belt's path.

There are several types of idler pulleys, such as

- Flat Idler Pulleys These provide a smooth surface for the belt to rest against. - Crowned Idler Pulleys With a slightly raised center, these pulleys help keep the belt centered and prevent lateral movement. - Troughing Idler Pulleys Designed to create a trough shape, these are used for transporting bulk materials, ensuring that they stay contained on the belt.

3. Snub Pulleys

types of conveyor belt pulleys

Snub pulleys are used to increase the angle of wrap of the conveyor belt around the drive pulley, enhancing the friction and grip required for effective belt movement. Positioned near the drive pulley, snub pulleys can significantly improve the starting and operational efficiency of the conveyor system.

These pulleys are particularly valuable in applications where heavy materials must be moved, as they help to transfer additional power to the belt. The increased wrap angle allows for a greater amount of tension to be applied to the belt, reducing the chances of slippage during startup.

4. Return Pulleys

Return pulleys, sometimes referred to as tail pulleys, are located at the end of the conveyor where the belt begins its return journey. Their primary function is to support the belt as it returns to the drive pulley for another cycle. They are typically designed with a simple cylindrical shape and can be equipped with scrapers or cleaners to remove any residual materials from the belt surface, ensuring longevity and efficient operation.

Return pulleys help maintain tension on the belt, ensuring that it remains taut throughout the entire system, thereby reducing the risk of damage or misalignment.

5. Take-Up Pulleys

Take-up pulleys are essential for maintaining the proper tension in the conveyor belt. They are used in take-up assemblies, which can either be manual or automatic. Take-up pulleys adjust the belt's tension to account for wear, stretch, or thermal expansion, ensuring that the belt operates smoothly at all times.

Proper tension is crucial to prevent slippage, misalignment, or excessive wear on both the pulleys and the belt itself. Take-up pulleys are vital for maximizing the lifespan and efficiency of the conveyor system.

Conclusion

Conveyor belt pulleys play an indispensable role in the functionality and efficiency of conveyor systems. Understanding the types of pulleys—drive, idler, snub, return, and take-up—enables operators to select the appropriate components for their specific applications. This selection is crucial for ensuring smooth operations, reducing downtime, and enhancing the overall productivity of material handling processes. By investing in high-quality pulleys and maintaining them regularly, businesses can achieve long-lasting performance from their conveyor systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025