Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 16, 2025 03:58

Back to list

types of belt cleaners

Belt cleaners are a vital component in the conveyor belt systems across various industries, ensuring efficient material handling by removing residue and preventing buildup, which mitigates maintenance costs and extends the conveyor belt's operational life. Understanding the different types of belt cleaners, along with their applications and benefits, is crucial for selecting the right product suited to specific industrial needs.

Another crucial variant is the V-Plow belt cleaner, a unique model designed to prevent material buildup on return belts. Installed on the underside of the return belt, these plows are particularly useful in protecting tail pulleys from debris and thus preventing potential malfunctions and increasing the lifespan of the conveyor system. V-Plows are versatile and essential for systems where minimizing maintenance interruptions is vital. In industries where maintenance access is limited or safety is a concern, self-adjusting belt cleaners, which automatically calibrate to maintain optimal tension and contact with the belt, are recommended. This adaptation reduces the need for manual adjustments, enhancing both the safety and efficiency of operations. While choosing belt cleaners, factors such as the type of material being conveyed, belt speed, and belt width must be considered. It's also crucial to assess the environmental conditions, such as temperature and humidity, which may affect the cleaner’s performance and durability. Investing in the right belt cleaner saves costs in the long run by extending the life of the belt, enhancing system efficiency, and reducing maintenance requirements. Industries ranging from mining and quarrying to food processing trust belt cleaners to keep conveyor systems running smoothly, optimizing production lines and ensuring safety standards are met. In summary, understanding the diverse types of belt cleaners—each with unique features suited to different operational needs—is key to implementing an effective belt cleaning strategy. From primary and secondary cleaners to specialized products like V-Plows and brush cleaners, the right choice ensures maximum efficiency, longevity, and reliability of conveyor systems, emphasizing the need for expertise and professional consultation in the field for optimal results.

Another crucial variant is the V-Plow belt cleaner, a unique model designed to prevent material buildup on return belts. Installed on the underside of the return belt, these plows are particularly useful in protecting tail pulleys from debris and thus preventing potential malfunctions and increasing the lifespan of the conveyor system. V-Plows are versatile and essential for systems where minimizing maintenance interruptions is vital. In industries where maintenance access is limited or safety is a concern, self-adjusting belt cleaners, which automatically calibrate to maintain optimal tension and contact with the belt, are recommended. This adaptation reduces the need for manual adjustments, enhancing both the safety and efficiency of operations. While choosing belt cleaners, factors such as the type of material being conveyed, belt speed, and belt width must be considered. It's also crucial to assess the environmental conditions, such as temperature and humidity, which may affect the cleaner’s performance and durability. Investing in the right belt cleaner saves costs in the long run by extending the life of the belt, enhancing system efficiency, and reducing maintenance requirements. Industries ranging from mining and quarrying to food processing trust belt cleaners to keep conveyor systems running smoothly, optimizing production lines and ensuring safety standards are met. In summary, understanding the diverse types of belt cleaners—each with unique features suited to different operational needs—is key to implementing an effective belt cleaning strategy. From primary and secondary cleaners to specialized products like V-Plows and brush cleaners, the right choice ensures maximum efficiency, longevity, and reliability of conveyor systems, emphasizing the need for expertise and professional consultation in the field for optimal results.

Next:

Latest news

-

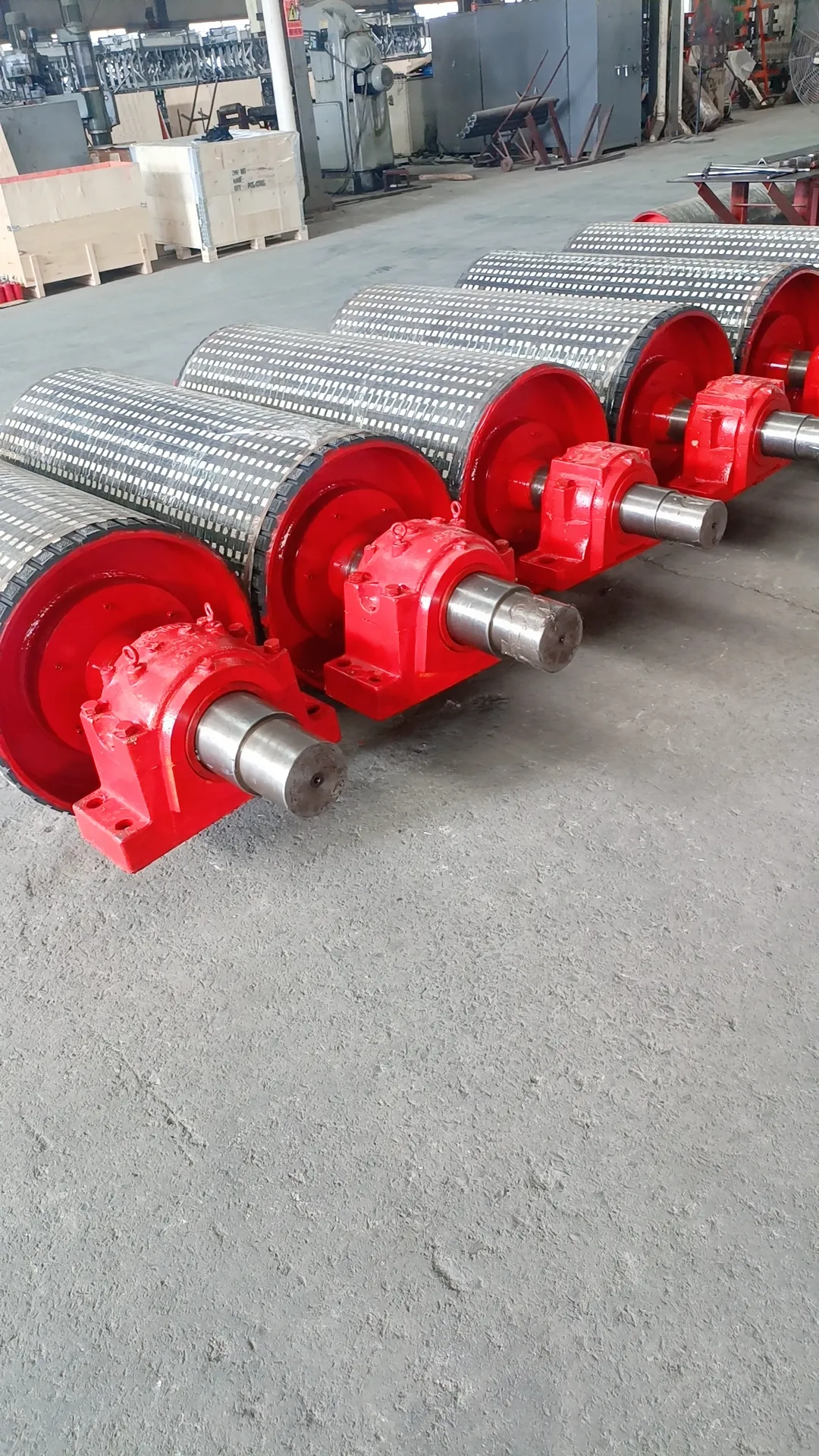

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS