Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu types of belt cleaners

Types of Belt Cleaners Ensuring Efficiency and Performance

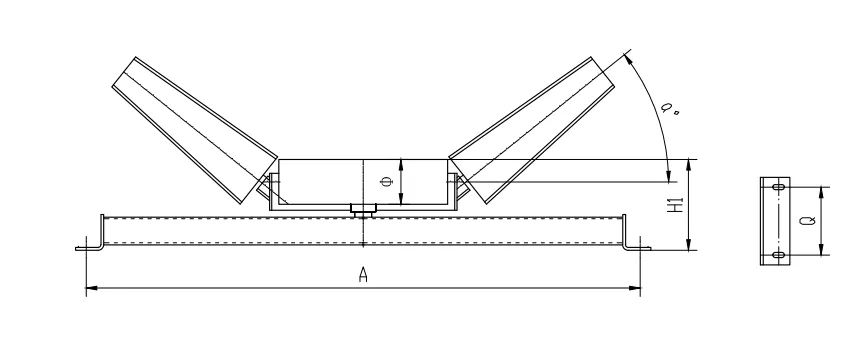

In many industrial settings, conveyor belts play a crucial role in material handling. To maintain their efficiency and extend their lifespan, effective cleaning solutions are essential. Belt cleaners are specific devices designed to remove material buildup from the surfaces of various types of belts, ensuring optimal performance. There are several types of belt cleaners available, each suited to different applications and challenges.

Types of Belt Cleaners Ensuring Efficiency and Performance

2. Secondary Belt Cleaners Installed further down the conveyor system, secondary cleaners work in conjunction with primary cleaners to remove residual material that was not cleaned off during the first pass. Secondary cleaners often feature multiple blades or enhanced cleaning technologies to ensure thorough cleaning. They are especially beneficial in operations where cleanliness is critical to avoid contamination of materials downstream.

types of belt cleaners

3. Specialty Cleaners These cleaners are tailored for specific applications or materials that require unique handling. For instance, magnetic belt cleaners are designed for magnetic materials, while air knife systems utilize high-velocity air to blow off debris without physical contact. Additionally, there are cleaners designed for high-temperature environments, capable of withstanding extreme heat without degrading.

4. Modular and Adjustable Cleaners Modular cleaners offer flexibility, allowing users to adjust the cleaning force and orientation based on the specific belt type and material characteristics. This adaptability helps maintain efficiency in diverse operational conditions.

5. Tensioned and Non-Tensioned Cleaners Tensioned cleaners, which apply constant pressure against the belt, are effective in maintaining contact and enhancing cleaning efficiency. Non-tensioned options, while easier to install and maintain, may require more frequent adjustments to ensure effective cleaning.

In conclusion, selecting the appropriate belt cleaner is vital for the maintenance of conveyor systems. Understanding the types available and their specific applications can lead to improved operational efficiency, reduced downtime, and extended life of the conveyor components. Investing in the right belt cleaning solutions is essential for any organization committed to maintaining an effective and productive material handling system.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025