Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Mar . 07, 2025 02:27

Back to list

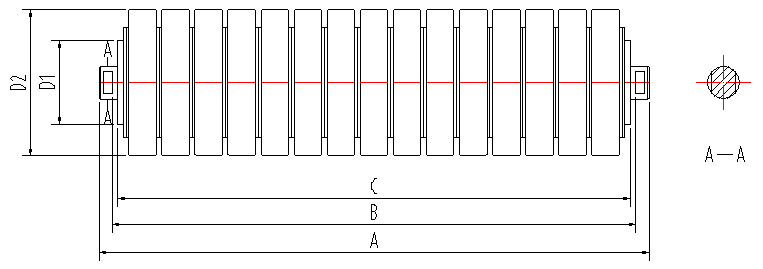

troughing roller

Troughing rollers are indispensable components in the material handling systems in industries like mining, agriculture, and manufacturing. They play a crucial role by supporting conveyor belts and facilitating the smooth transportation of bulk materials. Understanding their importance and functionality is imperative for businesses looking to enhance operational efficiency and optimize their conveyor systems.

The selection of troughing rollers requires a deep understanding of the conveyed material type, belt width, and carrying capacity. Attention to these details maximizes the effectiveness of the conveyor system and mitigates the risk of mechanical failures. For instance, operations handling abrasive substances like coal or gravel may opt for rollers with reinforced coatings to withstand material impact. Alternatively, industries dealing with food products may require rollers that comply with stringent hygiene standards, utilizing stainless steel to prevent contamination. Experienced practitioners in this field understand that regular maintenance and timely replacement of worn-out rollers can prevent the costly implications of conveyor malfunctions. Predictive maintenance strategies, enabled by technologies such as the Internet of Things (IoT), can alert operators to potential issues before they disrupt operations. This represents a proactive approach to asset management based on real-time data analysis and enhances operational reliability. Credibility in the discussion of troughing rollers extends to the manufacturers who supply them. Industry leaders employ rigorous testing protocols to ensure their products withstand the rigors of industrial use. Certifications from recognized authorities further cement the trustworthiness of these components, reassuring businesses of their operational integrity. These manufacturers also provide comprehensive customer support, offering expert guidance in product selection, installation, and troubleshooting, which ultimately maximizes the lifespan and efficacy of the rollers. Investing in quality troughing rollers provides tangible benefits, from enhanced durability and reduced operational costs to improved sustainability and optimized material flow. Businesses committed to continuous improvement in their material handling systems leverage these components to gain a competitive edge, ensuring reliability in their production lines and satisfaction in their service delivery. In conclusion, troughing rollers represent an essential intersection between engineering excellence and practical application in conveyor systems. Their role in shaping and sustaining efficient material transport cannot be understated, making them a focal point of investment for industries dedicated to operational excellence. Through strategic selection, ongoing technological innovation, and proactive maintenance, these rollers continue to drive productivity and profitability in robust industrial landscapes.

The selection of troughing rollers requires a deep understanding of the conveyed material type, belt width, and carrying capacity. Attention to these details maximizes the effectiveness of the conveyor system and mitigates the risk of mechanical failures. For instance, operations handling abrasive substances like coal or gravel may opt for rollers with reinforced coatings to withstand material impact. Alternatively, industries dealing with food products may require rollers that comply with stringent hygiene standards, utilizing stainless steel to prevent contamination. Experienced practitioners in this field understand that regular maintenance and timely replacement of worn-out rollers can prevent the costly implications of conveyor malfunctions. Predictive maintenance strategies, enabled by technologies such as the Internet of Things (IoT), can alert operators to potential issues before they disrupt operations. This represents a proactive approach to asset management based on real-time data analysis and enhances operational reliability. Credibility in the discussion of troughing rollers extends to the manufacturers who supply them. Industry leaders employ rigorous testing protocols to ensure their products withstand the rigors of industrial use. Certifications from recognized authorities further cement the trustworthiness of these components, reassuring businesses of their operational integrity. These manufacturers also provide comprehensive customer support, offering expert guidance in product selection, installation, and troubleshooting, which ultimately maximizes the lifespan and efficacy of the rollers. Investing in quality troughing rollers provides tangible benefits, from enhanced durability and reduced operational costs to improved sustainability and optimized material flow. Businesses committed to continuous improvement in their material handling systems leverage these components to gain a competitive edge, ensuring reliability in their production lines and satisfaction in their service delivery. In conclusion, troughing rollers represent an essential intersection between engineering excellence and practical application in conveyor systems. Their role in shaping and sustaining efficient material transport cannot be understated, making them a focal point of investment for industries dedicated to operational excellence. Through strategic selection, ongoing technological innovation, and proactive maintenance, these rollers continue to drive productivity and profitability in robust industrial landscapes.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS